Brushless motor controller system facilitating mos transistor heat radiation

A mos tube, brushless motor technology, applied in the direction of a single motor speed/torque control, electric solid device, circuit, etc., can solve the problems of poor heat dissipation effect, increased power loss of mos tube, overheating damage, etc., which is conducive to heat dissipation. The effect of cooling, avoiding the increase of power loss and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

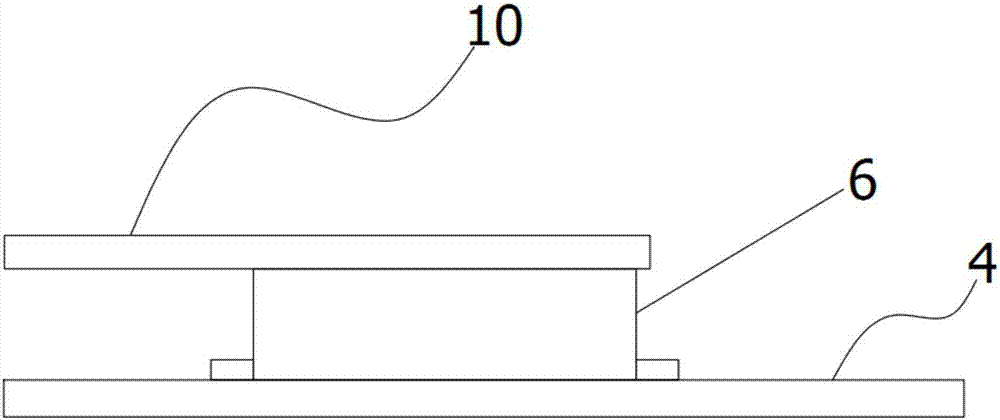

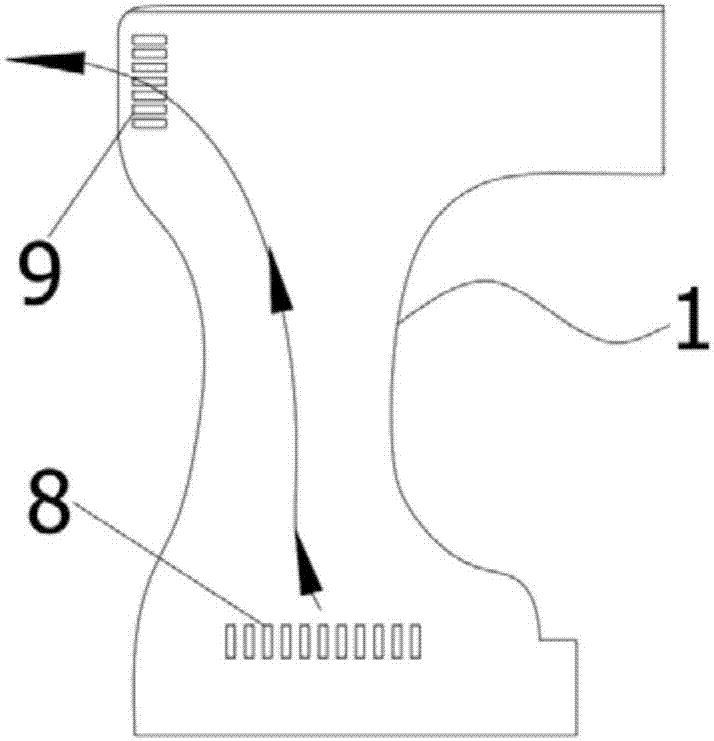

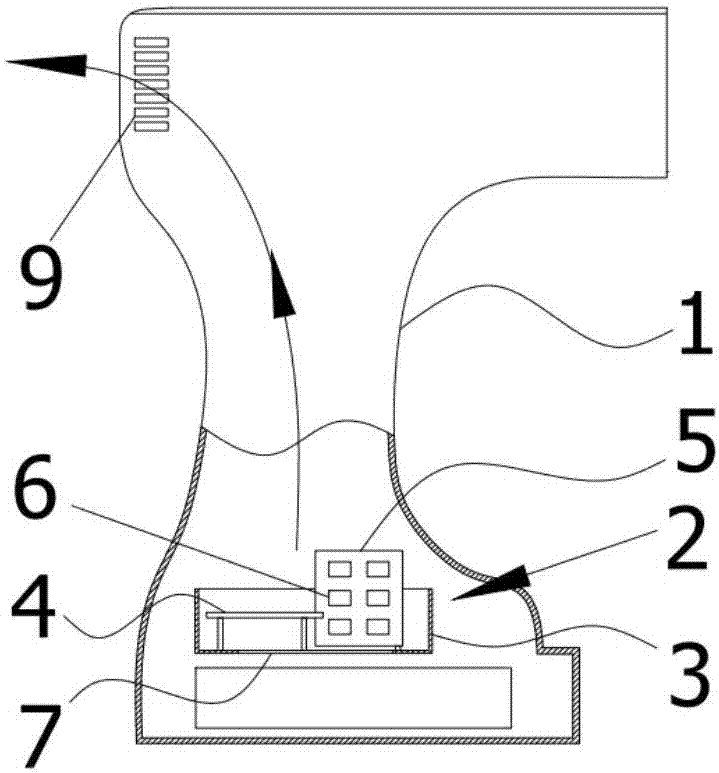

[0037] This embodiment provides a brushless motor controller system that facilitates the heat dissipation of the mos tube 6, wherein: figure 2The outline drawing of the brushless motor controller system that is beneficial to the heat dissipation of mos tube 6 provided by the present invention; image 3 A cross-sectional view of the controller 2 part of the brushless motor controller system that facilitates the heat dissipation of the mos tube 6 provided by the present invention; Figure 4 A schematic structural view of the ventilation base of the brushless motor controller system that is beneficial to the heat dissipation of the mos tube 6 provided by the present invention; Figure 5 A schematic structural diagram of the controller 2 of the brushless motor controller system that facilitates the heat dissipation of the mos tube 6 provided by Embodiment 1 of the present invention. like Figure 2-5 As shown, the brushless motor controller system provided by this embodiment to ...

Embodiment 2

[0046] This embodiment provides a brushless motor controller system that facilitates the heat dissipation of the mos tube 6, wherein: Image 6 A schematic structural diagram of the controller 2 of the brushless motor controller system that facilitates the heat dissipation of the mos tube 6 provided by Embodiment 2 of the present invention. like Figure 2~4 As shown in , 6 , the brushless motor controller system provided by this embodiment, which facilitates the heat dissipation of the mos tube 6 , includes a housing 1 , a motor body built in the housing 1 , and a controller 2 . The motor body and the controller 2 are electrically connected to each other.

[0047] Specifically, the controller 2 includes a ventilation base 3, a first circuit board 4, and a second circuit board 5;

[0048] Wherein, the mos tube 6 of the controller 2 is arranged on the second circuit board 5, and the remaining electronic components of the controller 2 are arranged on the first circuit board 4, a...

Embodiment 3

[0054] This embodiment provides a brushless motor controller system that facilitates the heat dissipation of the mos tube 6, wherein: Figure 7 A schematic structural diagram of the controller 2 of the brushless motor controller system that facilitates the heat dissipation of the mos tube 6 provided by Embodiment 3 of the present invention. like Figure 2~4 As shown in , 7 , the brushless motor controller system provided by this embodiment, which facilitates the heat dissipation of the mos tube 6 , includes a housing 1 , a motor body built in the housing 1 , and a controller 2 . The motor body and the controller 2 are electrically connected to each other.

[0055] Specifically, the controller 2 includes a ventilation base 3, a first circuit board 4, and a second circuit board 5;

[0056] Wherein, the mos tube 6 of the controller 2 is arranged on the second circuit board 5, and the remaining electronic components of the controller 2 are arranged on the first circuit board 4, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com