Drying and degassing unit for printing machines

An air box technology for printing presses, applied in printing presses, general parts of printing machinery, printing and other directions, can solve problems affecting work quality and efficiency, pollute the environment, and a large amount of volatilization, so as to protect the environment, reduce pollution, occupy The effect of reducing the ground space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

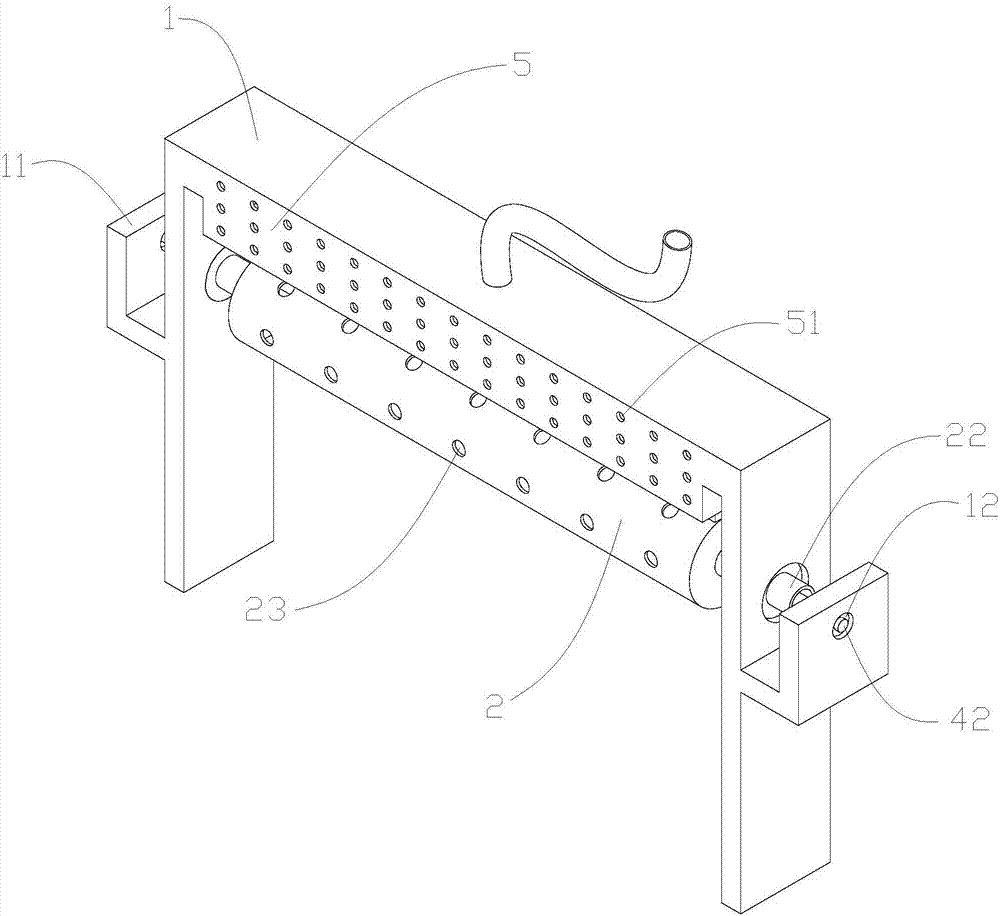

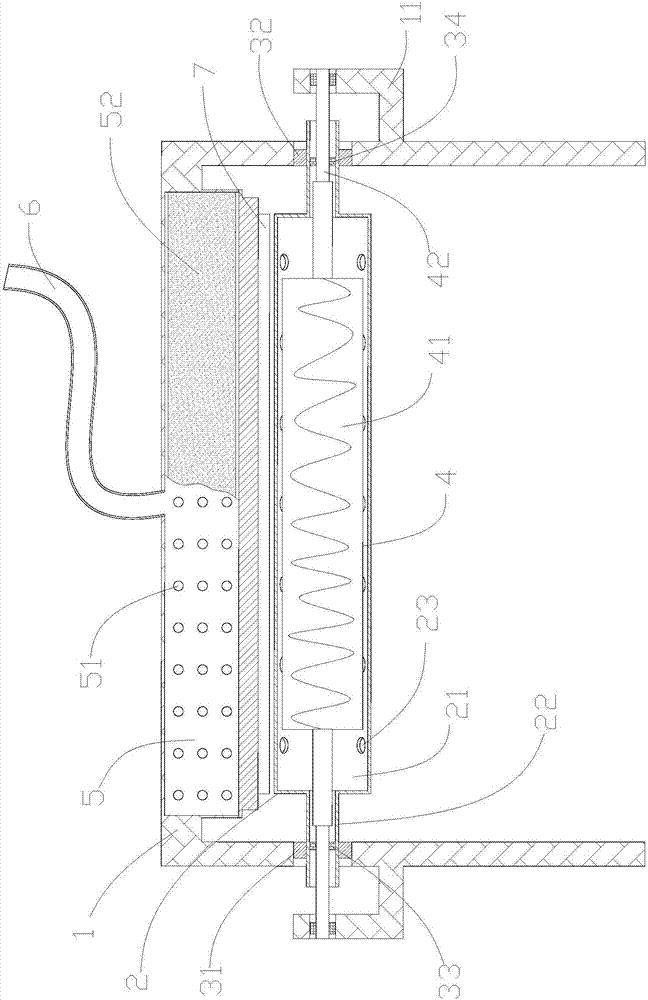

[0022] like figure 1 , figure 2 As shown, the present invention discloses a drying and degassing unit for a printing machine, which includes a frame 1, a paper transfer roller 2 and a degassing box 5, and the paper transfer roller 2 and the degassing box 5 are fixed on the on the frame 1, and the degassing box 5 is located above the paper transfer roller 2; The roller shaft 22 is respectively fixed on the frame 1 through the first bearing 31 and the second bearing 32, the roller body 21 and the roller shaft 22 are all penetrated along the axis, and the inside of the two roller shafts 22 are respectively The third bearing 33 and the fourth bearing 34 are fixedly provided; the paper transfer roller 2 is provided with a heating pipe 4, and the heating pipe 4 includes a pipe body 41 and conductive ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com