Heating device of new energy passenger car

A warm air device and new energy technology, applied in vehicle parts, transportation and packaging, heating/cooling equipment, etc., can solve the problems of easy pollution of the environment, insufficient comfort, low efficiency, etc., and achieve uniform temperature, comfort and safety Good performance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

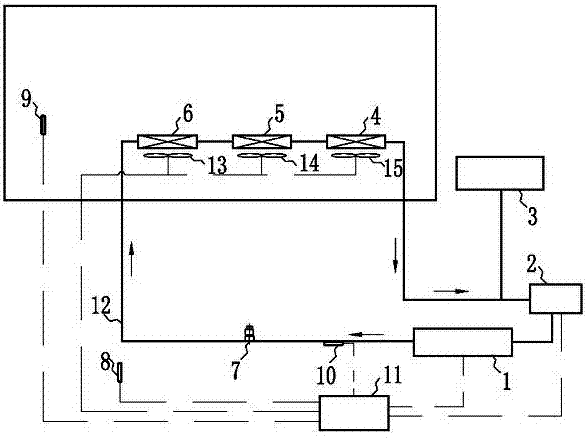

[0042] see figure 1 . The invention relates to a connection structure of water heating series for a heater device of a new energy bus, which includes a PTC liquid heater 1, a water pump 2, an expansion water tank 3, a first heater core 4, a second heater core 5, a third heater Air core 6, exhaust valve 7, first temperature sensor 8, second temperature sensor 9, third temperature sensor 10, controller 11, pipeline 12, first warm air blower 13, second warm air blower 14 and The third heater blower 15. The warm air device is a closed circulation system, which uses antifreeze and antirust liquid with certain insulation capacity as the circulating fluid, and the circulation is realized under the power of the water pump 2 .

[0043] Connect the inlet end of the PTC liquid heater 1 to the water outlet of the water pump 2 through the pipeline 12, and connect the water inlet (also the water return port) of the water pump 2 to the expansion tank 3 and the first heater through the pipe...

Embodiment 2

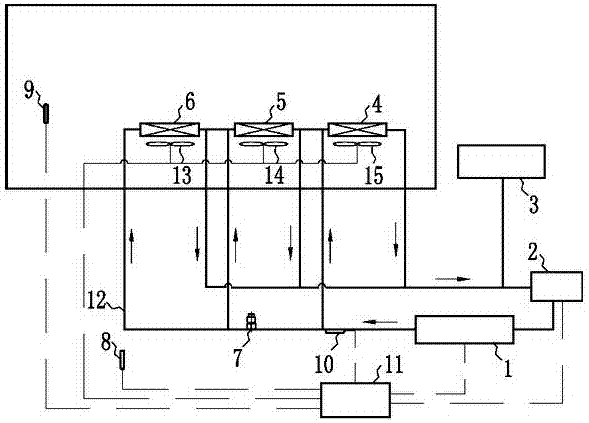

[0048] see figure 2 . The invention relates to a water heating parallel connection structure for a heater device of a new energy bus, comprising a PTC liquid heater 1, a water pump 2, an expansion water tank 3, a first heater core 4, a second heater core 5, a third heater Air core 6, exhaust valve 7, first temperature sensor 8, second temperature sensor 9, third temperature sensor 10, controller 11, pipeline 12, first warm air blower 13, second warm air blower 14 and The third heater blower 15. The warm air device is a closed circulation system, which uses antifreeze and antirust liquid with certain insulation capacity as the circulating fluid, and the circulation is realized under the power of the water pump 2 .

[0049] Connect the inlet end of the PTC liquid heater 1 to the water outlet of the water pump 2 through the pipeline 12, and connect the water inlet (also the water return port) of the water pump 2 to the expansion tank 3 and the first heater through the pipeline...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com