Novel diversion enhanced oxygen dissolving and mass transferring sewage processing tower

A technology of sewage treatment and dissolved oxygen, applied in biological water/sewage treatment, water/sludge/sewage treatment, aerobic process treatment, etc. and other problems, to achieve the effect of saving floor space, saving operating costs, and realizing multiple recycling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

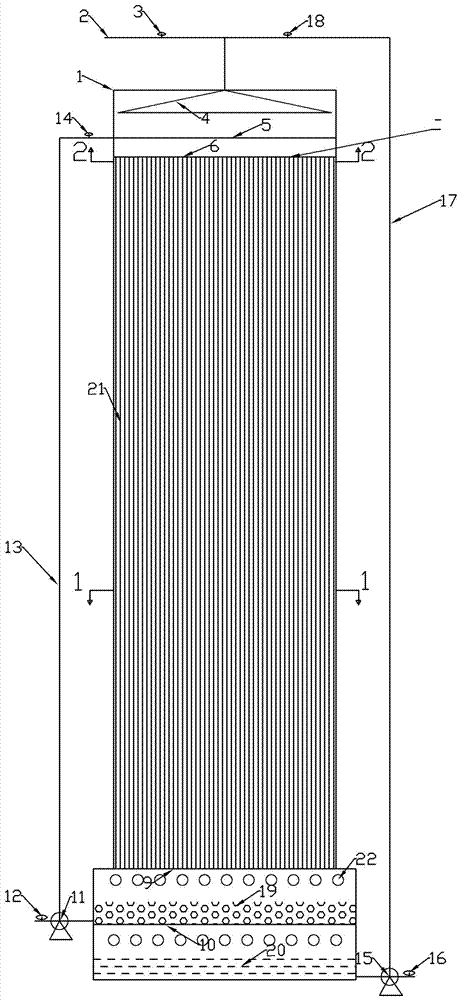

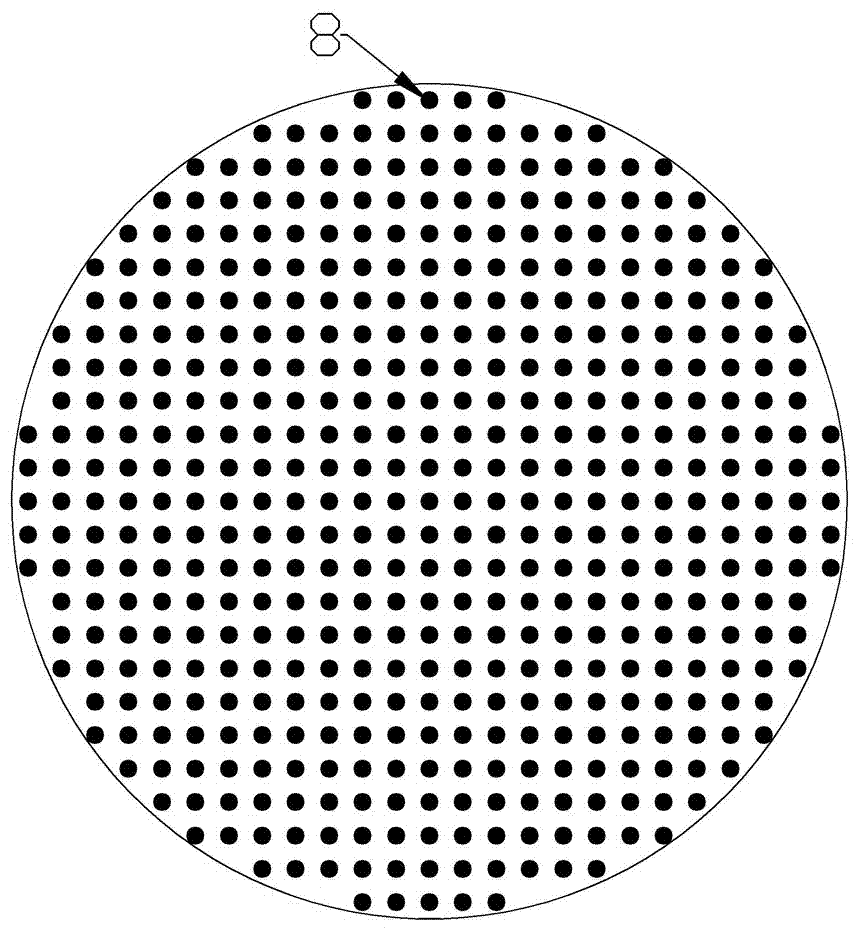

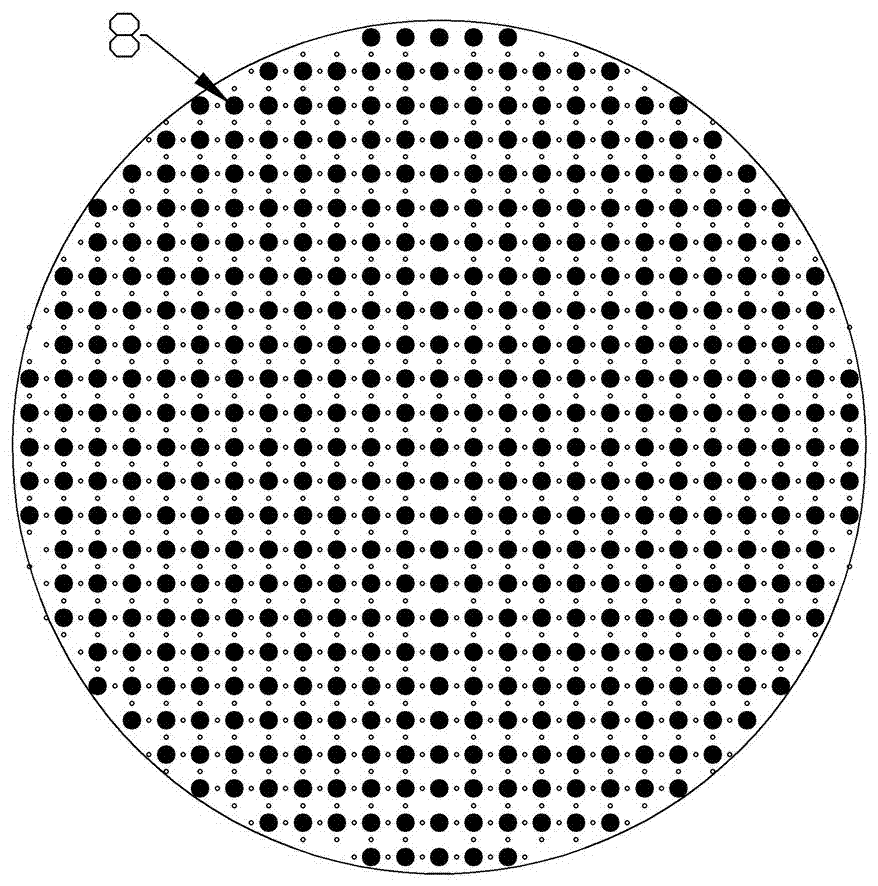

[0022] Such as figure 1 As shown, the structure schematic diagram of the sewage treatment tower of the novel flow diversion enhanced dissolved oxygen and mass transfer of the present invention is provided, which consists of tower body 1, water inlet pipe 2, water distributor 4, mud distribution plate 5, diversion grid 6 , a contact grid 8, a fixed plate with holes 9, a sludge retention plate 10, a sludge lifting pump 11, a sludge return pipe 13, a sewage lifting pump 15, and a sewage return pipe 17. The upper end of the tower body 1 shown is open, and the inner for the cavity. The diversion grid 6 and the fixed plate with holes 9 are arranged on the upper and lower parts of the inner cavity of the tower body 1 respectively, which divide the inner cavity of the tower body 1 from top to bottom into a water distribution and mud distribution area and a con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com