Environment-friendly paving brick for efficiently purifying air and manufacturing method thereof

A technology for purifying air and paving bricks, which is applied to pavements, roads, roads and other directions paved with prefabricated blocks. , the effect of protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

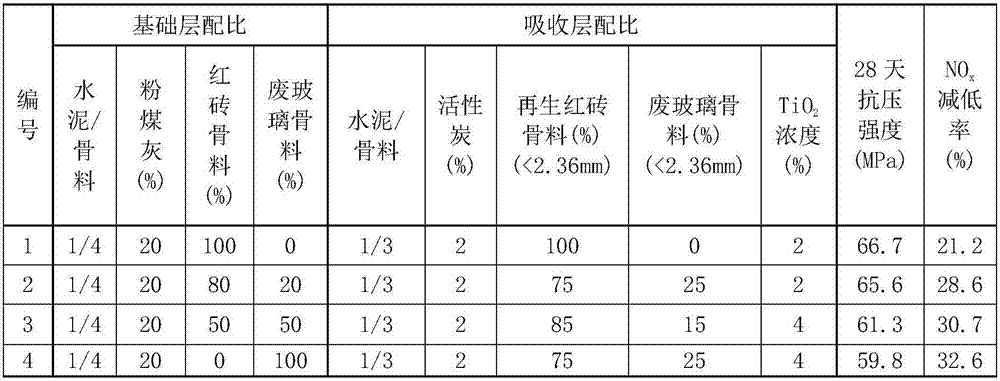

[0025] Produce concrete paving bricks according to the ratio in Table 1. Compressive strength and NO x The method for determining the rate of reduction is recognized in the art.

[0026] From the ratio listed in Table 1 and the characteristics of the produced concrete paving bricks, it can be seen that due to the increase in the amount of waste glass aggregate, the strength of the paving bricks has decreased, but the strength of all concrete paving bricks still reaches above 49MPa. Fully meet the requirements of Hong Kong Building Code and British Standards. Under the same content of titanium dioxide, when waste glass aggregates are added, the brick has no effect on NO x The reduction rate increases, which is mainly due to the increase in the probability of titanium dioxide participating in the reaction due to the refraction of light by glass.

[0027] Table 1. Proportion and performance measurement results of environmentally friendly bricks

[0028]

[0029] Note: In T...

Embodiment 2

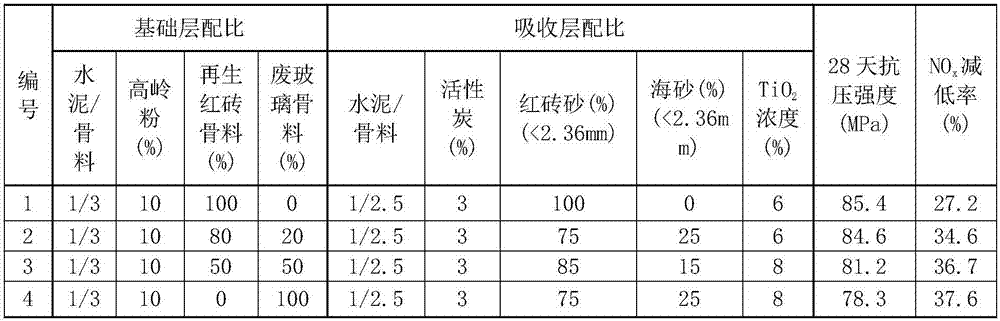

[0031] Proportionally produce concrete paving bricks according to Table 2. And measure the compressive strength and NO x reduction rate.

[0032] From the listed proportions of Table 2 and the characteristics of the manufactured concrete paving bricks, it can be seen that the compressive strength of the bricks increases due to the increase in the amount of cement, compared with Example 1, the content of titanium dioxide increases, and the NO x The reduction rate increases, but when the titanium dioxide exceeds 6%, the increase in the absorption rate is not obvious.

[0033] Table 2. Proportion and performance measurement results of environmentally friendly bricks

[0034]

Embodiment 3

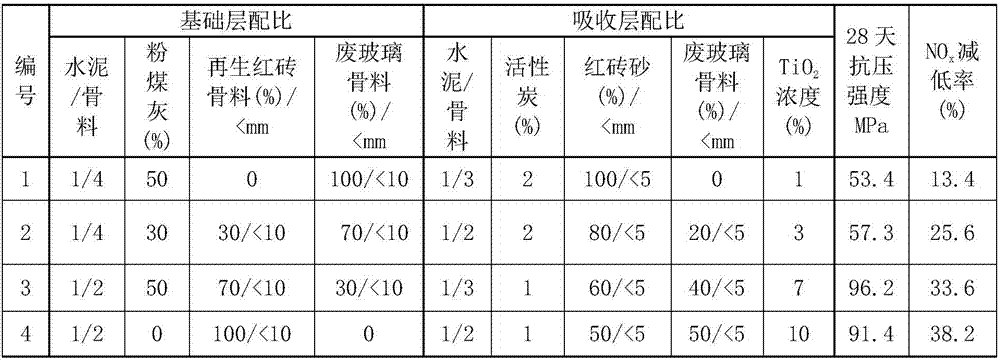

[0036] Produce concrete paving bricks according to the ratio in Table 3. And measure the compressive strength and NO x reduction rate.

[0037] It can be seen that the paving bricks manufactured according to the ratio in the table can obtain good compressive strength and NO x Reduce rate.

[0038] Table 3. Proportion and performance measurement results of environmentally friendly bricks

[0039]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com