Planar waxy split leather and manufacturing method thereof

A production method and technology of two-layer leather, which are applied in the directions of leather softening, leather drying, leather surface mechanical treatment, etc., can solve the problems of scratch resistance on the surface, easy discoloration of oil wax leather, uneven leather surface, etc. , to achieve the effect of soft hand feeling and no greasy feeling, easy operation of the production method, and good resistance to dry and wet rubbing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

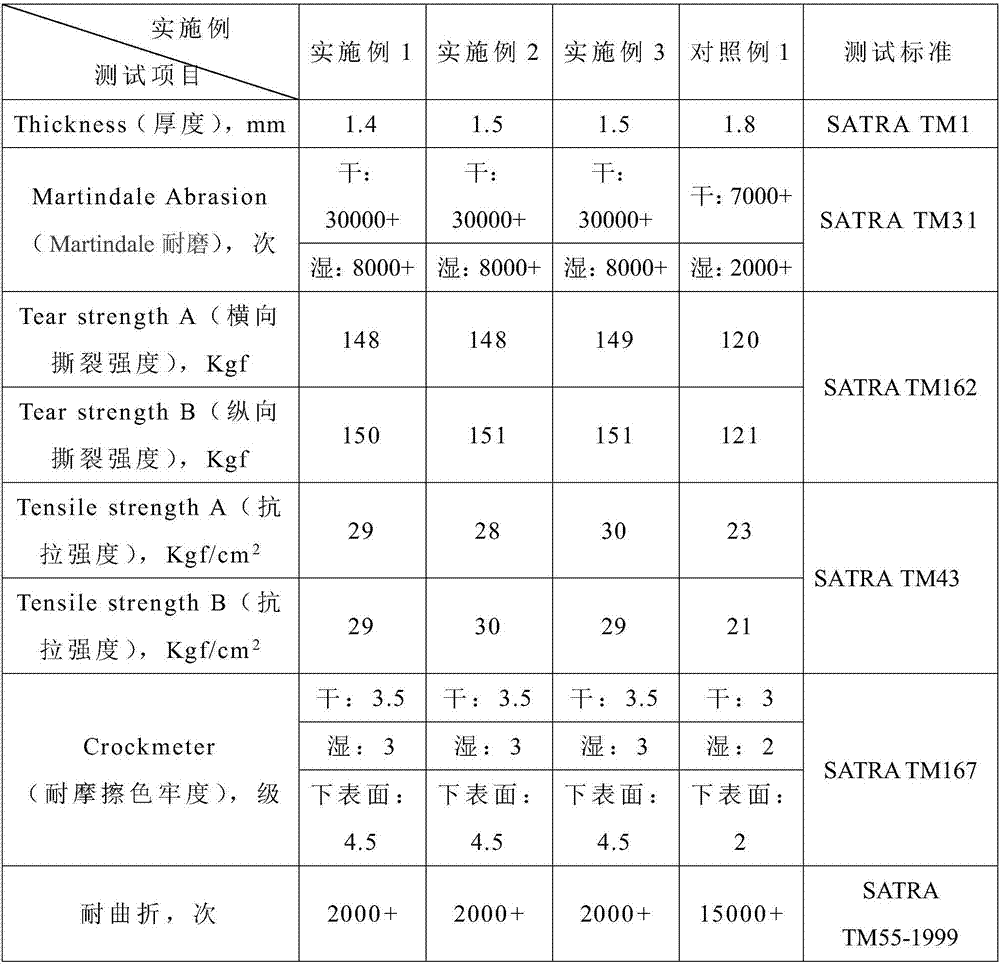

Examples

Embodiment 1

[0034] The preparation method of the two-layer plane waxy oily wax skin specifically includes the following steps:

[0035] Step 1: Take the processed and dyed split skin, dry the split skin once, and vibrate to soften it to obtain vibrated soft skin. When vibrating, the vibrating value is set to 6, and the speed is 0.6cm / s;

[0036] Step 2: Grind the leather once, and use 180 # 、220 # Sand the bottom with 180 # 、280 # Grind the surface with sandpaper to get a buffed leather;

[0037] Step 3, Roller coating: Roll the paint onto the surface of the first-time grinding leather obtained in Step 2, and roll-coat it twice continuously to obtain a roll-coated leather. The ratio of rolling speed to conveyor belt speed during rolling coating is 20:10, and rolling twice The amount of wet coating applied is: 10g / SF for the first time and 6g / SF for the second time. The coating includes the following components in parts by mass: 600 parts of water, 400 parts of water-based polyacrylate...

Embodiment 2

[0047] The preparation method of the two-layer plane waxy oily wax skin specifically includes the following steps:

[0048] Step 1: Take the processed and dyed split skin, dry the split skin once, and vibrate until softened to obtain vibrated soft skin. When vibrating, the vibrating value is set to 7, and the speed is 0.7cm / s;

[0049] Step 2: Grind the leather once, and use 180 # 、220 # Sand the bottom with 180 # 、280 # Grind the surface with sandpaper to get a buffed leather;

[0050] Step 3, Roller coating: Roll the paint onto the surface of the first-time grinding leather obtained in Step 2, and roll-coat it twice continuously to obtain a roll-coated leather. The ratio of rolling speed to conveyor belt speed during rolling coating is 20:10, and rolling twice The amount of wet coating applied is: 8g / SF for the first time and 4g / SF for the second time. The coating includes the following components in parts by mass: 550 parts of water, 350 parts of water-based polyacrylat...

Embodiment 3

[0060] The preparation method of the two-layer plane waxy oily wax skin specifically includes the following steps:

[0061] Step 1: Take the processed and dyed split skin, dry the split skin once, and vibrate to soften it to obtain vibrated soft skin. When vibrating, the vibrating value is set to 6, and the speed is 0.5cm / s;

[0062] Step 2: Grind the leather once, and use 180 # 、220 # Sand the bottom with 180 # 、280 # Grind the surface with sandpaper to get a buffed leather;

[0063] Step 3, Roller coating: Roll the paint onto the surface of the first-time grinding leather obtained in Step 2, and roll-coat it twice continuously to obtain a roll-coated leather. The ratio of rolling speed to conveyor belt speed during rolling coating is 20:10, and rolling twice The amount of wet coating applied is: 12g / SF for the first time and 8g / SF for the second time. The coating includes the following components in parts by mass: 650 parts of water, 450 parts of water-based polyacrylate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com