Horizontal type foam pump

A foam pump, horizontal technology, applied in the field of horizontal foam pumps, can solve the problems of pump cut-off, reduced conveying capacity, difficult discharge, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

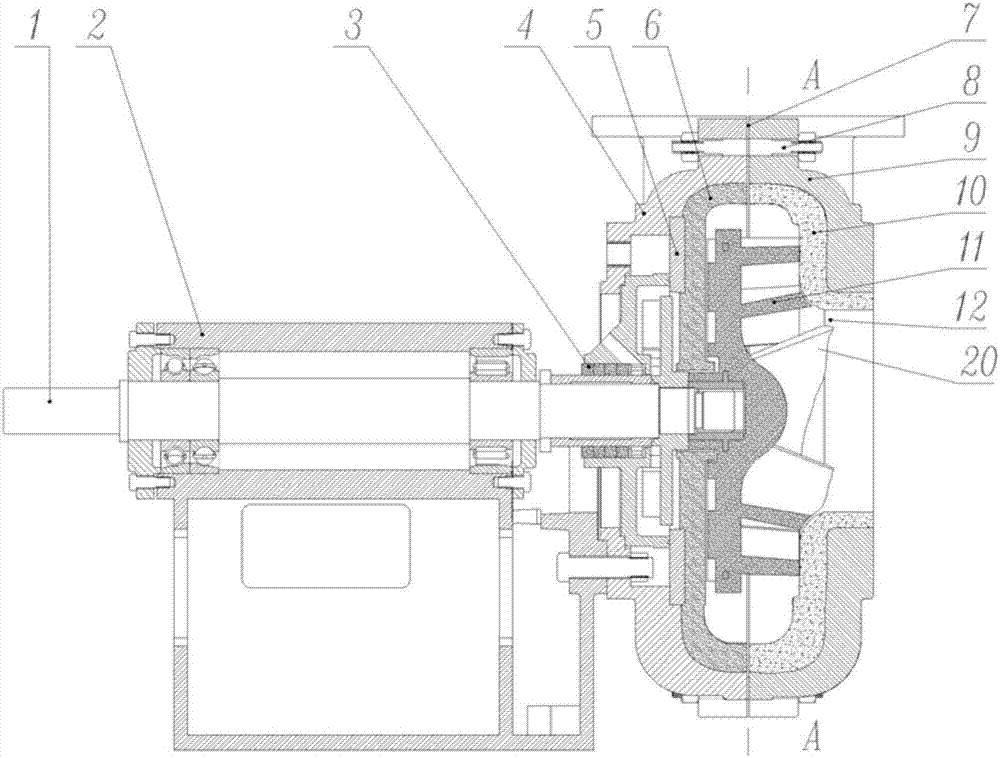

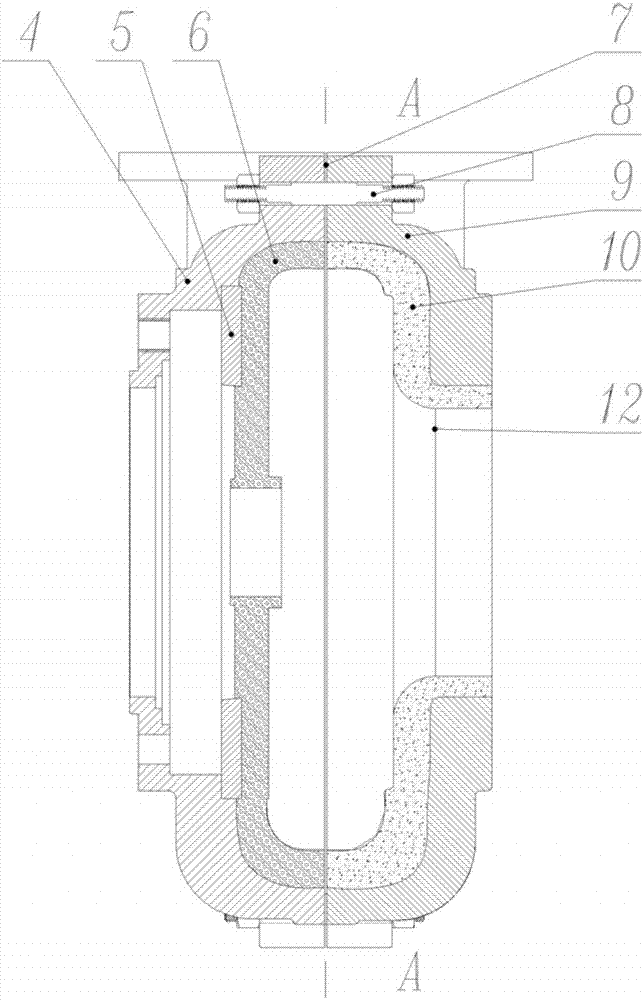

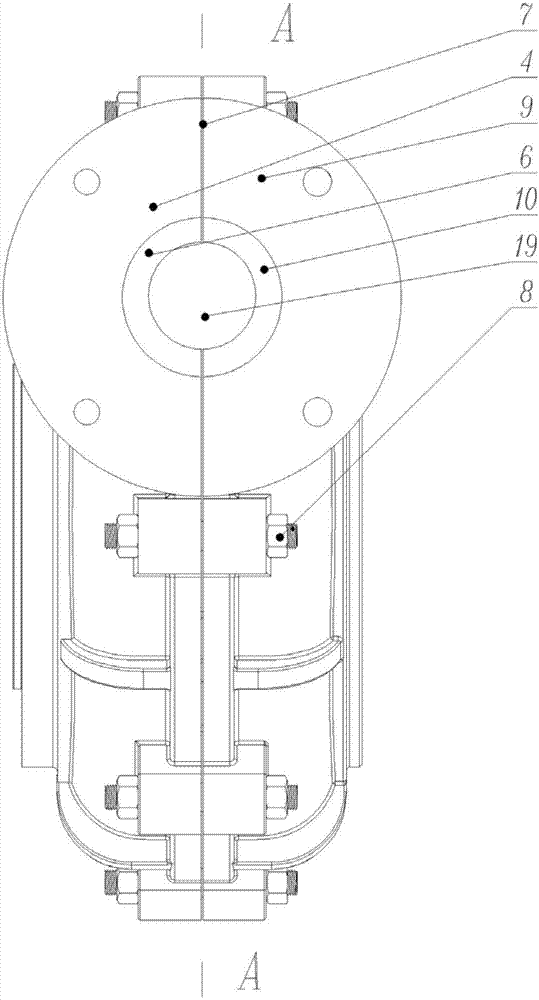

[0043] Such as Figure 1-7 as well as Figure 9As shown, a horizontal foam pump includes a pump body, the pump body is provided with a suction port 12 and a discharge port 19, the pump body is provided with an impeller 11, and the impeller 11 is provided with 3- Five main blades 13 and the same number of splitter blades 14; the splitter blades 14 are distributed between two adjacent main blades 13.

[0044] In practical applications, the setting of the splitter vanes 14 can significantly reduce the circulation intensity between the vanes, such as Figure 8 The middle is an ordinary foam pump impeller, its rotation direction is counterclockwise as shown by the arrow, and the generated circulation 16 is clockwise. And as Figure 6 The impeller of the shown embodiment 1 also rotates counterclockwise. Due to the arrangement of the splitter blades 14, the intensity of the circulation 17 is relatively high. Figure 8 The circular flow 16 in the conventional foam pump impeller sh...

Embodiment 2

[0058] Figure 10 , Figure 11 , Figure 12 In the shown embodiment 2, the impeller 11 is made of high chromium alloy, and its main blade 13 is twisted at the inlet end 18, and the inlet end 18 extends to the suction port 12. The length of the splitter blade is 0.56 times the length of the main blade, and the front inner The lining 10 and the rear inner lining 6 are made of rubber. A front sealing lip 21 is arranged on the outer edge of the front inner lining 10, and a rear sealing lip 22 is also arranged on the corresponding position of the rear inner lining 6. The rest of the structure Similar to Example 1. The manufacturing cost of this embodiment is relatively low, and is suitable for light abrasive working conditions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com