Metal bayonet for preparing metal detonating cord and cooling method

A cooling method and detonating cord technology, used in offensive equipment, ammunition, weapon accessories, etc., can solve problems such as intrinsic safety threats and dangers, and achieve the effect of improving intrinsic safety levels, simplifying production links, and overcoming potential dangers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

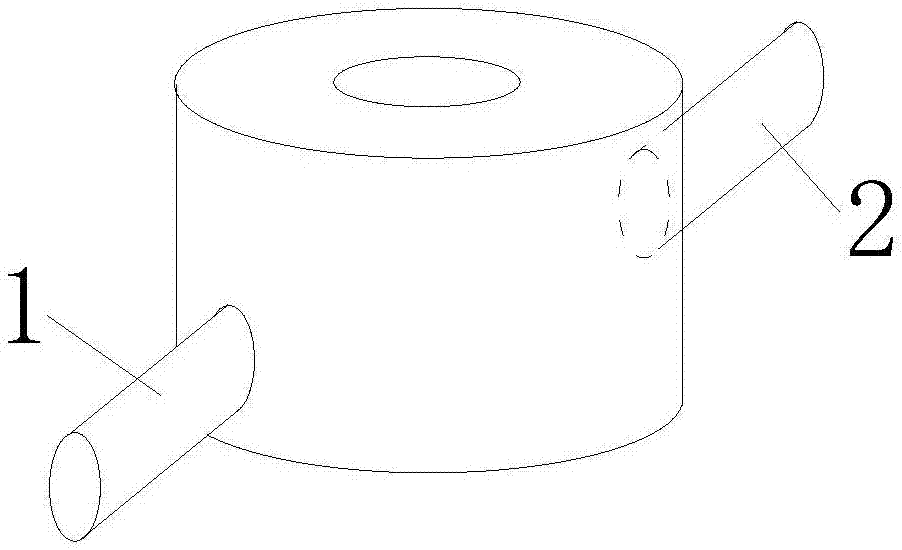

[0025] A metal bayonet for preparing a metal detonating cord, the metal bayonet has a tubular structure, its height is 50 mm, the outer diameter of the tube is 100 mm; the inner diameter of the tube is 1 mm, and the upper end of the metal bayonet is 5 mm away from the lower port. Circular branch port A, metal bayonet is provided with circular branch port B at a distance of 5 mm from the upper end port, the meridian position of circular branch port A and circular branch port B is symmetrical, and the metal bayonet is made of hard alloy become.

[0026] A cooling method for preparing a metal detonating cord, the steps of the method are as follows: step 1: turn on the low-temperature medium refrigerator, the low-temperature medium is liquid nitrogen, and pre-cool the metal bayonet; step 2: the temperature of the metal bayonet reaches -5°C At the same time, start the cable making machine, use fine cotton thread to guide Taian powder single substance medicine, use kraft paper as th...

Embodiment 2

[0028] A metal bayonet for preparing a metal detonating cord, the metal bayonet has a tubular structure, its height is 200mm, the outer diameter of the tube is 300mm; There is a circular branch port A, and a circular branch port B is provided at a distance of 30 mm from the upper port on the tubular metal bayonet. The meridian positions of the circular branch port A and the circular branch port B are symmetrical. Alloy.

[0029] A cooling method for preparing a metal detonating cord, the method steps are as follows: Step 1: Turn on the low-temperature medium refrigerator, the low-temperature medium is a mixture of ethylene glycol / water, and pre-cool the metal bayonet; Step 2: The temperature of the metal bayonet When the temperature reaches 0°C, start the cable-making machine, use fine cotton thread to introduce Taian powder single substance drug, use kraft paper as the drug core coating layer, and use the cable-making machine to guide the metal foil steadily at a rolling spee...

Embodiment 3

[0031] A metal bayonet for preparing a metal detonating cord, the metal bayonet has a tubular structure, its height is 70 mm, the outer diameter of the tube is 150 mm; the inner diameter of the tube is 3 mm, and the upper end of the tubular metal bayonet member is 10 mm away from the lower end port There is a circular branch port A, and the metal bayonet member is provided with a circular branch port B at a distance of 10 mm from the upper end port. The meridian positions of the circular branch port A and the circular branch port B are symmetrical. Made of quality alloy.

[0032] A cooling method for preparing a metal detonating cord, the method steps are as follows: step 1: turn on the low-temperature medium refrigerator, low-temperature medium sodium chloride aqueous solution, and pre-cool the metal bayonet; step 2: the temperature of the metal bayonet reaches 15°C At the same time, start the cable making machine, use fine cotton thread to lead down the powdery single substa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com