Ultrasonic flowmeter probe disassembling and assembling method

A disassembly method and flowmeter technology, which is applied in the direction of measuring devices, volume measurement, measuring flow/mass flow, etc., can solve the problems of measurement system inaccuracy, probe measurement influence, probe pull-out, etc., so as to reduce accident losses and shorten Accident handling time and the effect of avoiding wind-off accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

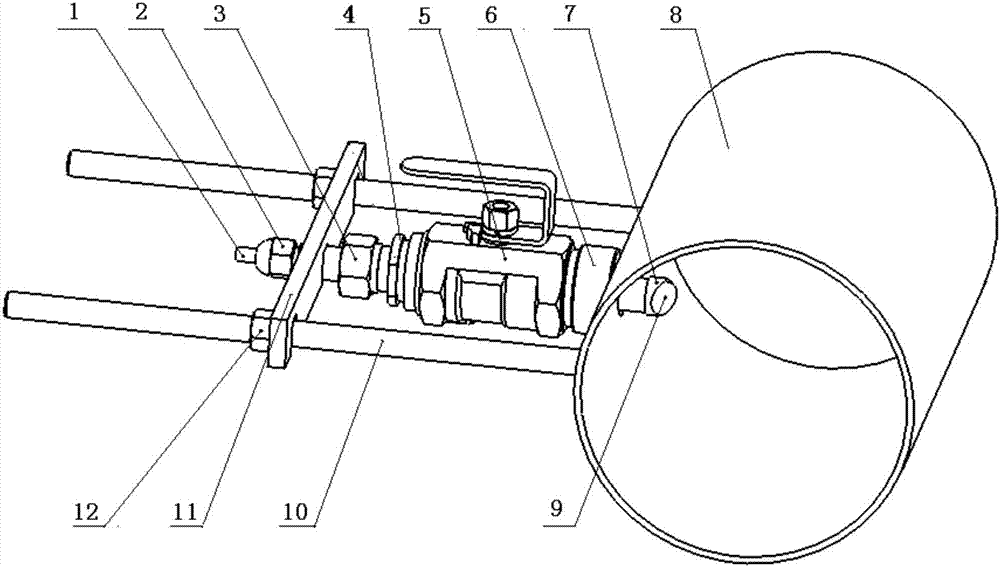

[0021] Depend on figure 1 It can be seen that the ultrasonic flowmeter probe is mainly composed of signal cable 1, outlet nut 2, lock nut 3, connection nut 4, ball valve 5, connection seat 6, probe rod 7 and acoustic wedge surface 9. The specific steps of the ultrasonic flowmeter probe disassembly and cleaning method of the present invention are:

[0022] 1. Prepare the screw rod 10, the clamping plate 11 and the positioning nut 12. Clamp 11 series adopts the steel plate processing of long 300mm, wide 30mm, thick 10mm to form. Have three grooves with a depth of 20mm and a width of 14mm at equal intervals on the wide surface of one side of the clamping plate 11. At the same time, two M14 screw rods 10 with full threads and two positioning nuts 12 matched with the screw rods 10 were prepared. The length of the screw rods 10 was 340 mm, which was 100 mm longer than the length of the ultrasonic flowmeter probe.

[0023] 2. Weld two screw rods 10 with positioning nuts 12 to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap