System and method for monitoring the spontaneous combustion in round coal yard

A monitoring system and self-ignition technology, applied in thermometer parts, measuring devices, instruments, etc., can solve the problems of smashed sensors, difficult sensor replacement and maintenance, etc., to facilitate replacement, reduce blind spots in temperature monitoring, and reduce costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

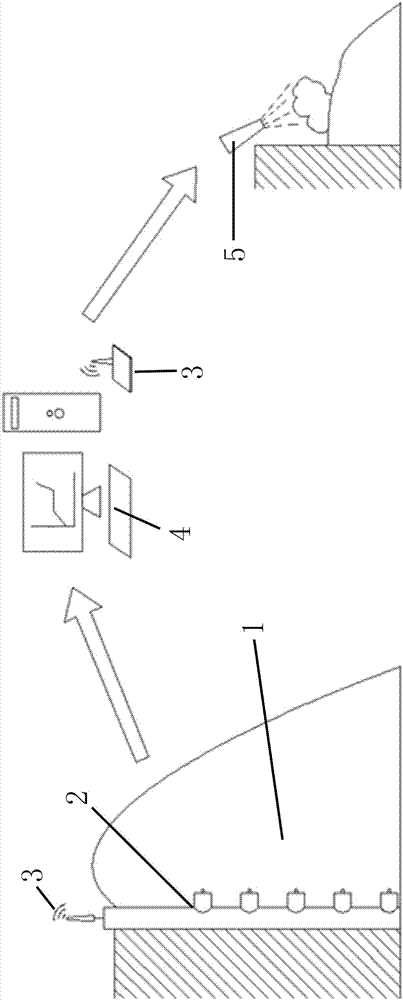

[0034] as attached figure 1 As shown, the coal yard temperature monitoring system includes a temperature data acquisition module 2 for collecting coal pile temperature data, a data transmission and reception module 3 for wirelessly transmitting and receiving the collected data, and a data processing module 4 for processing the received data , a spontaneous combustion control module 5 that performs spontaneous combustion control on the coal pile according to the temperature data of the coal pile.

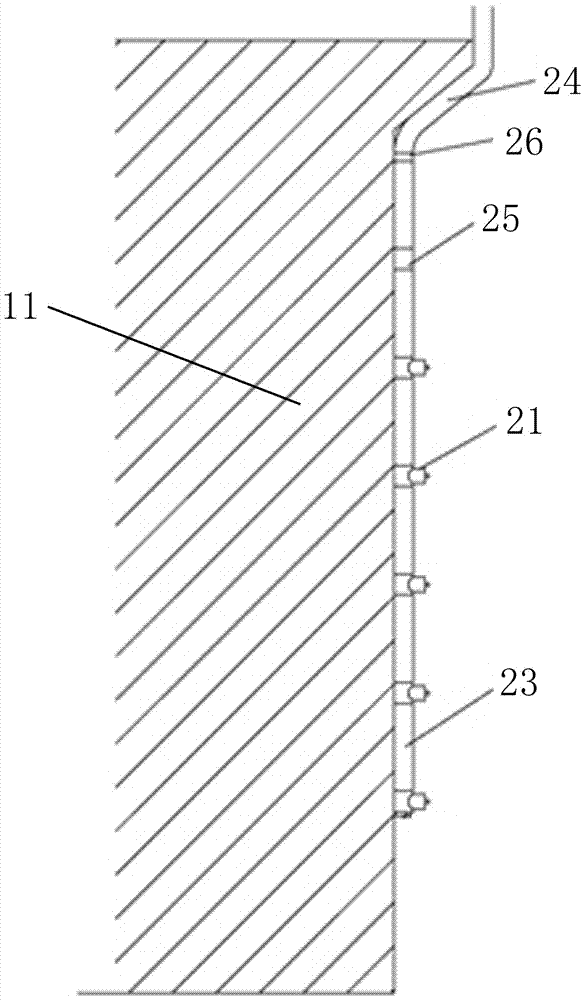

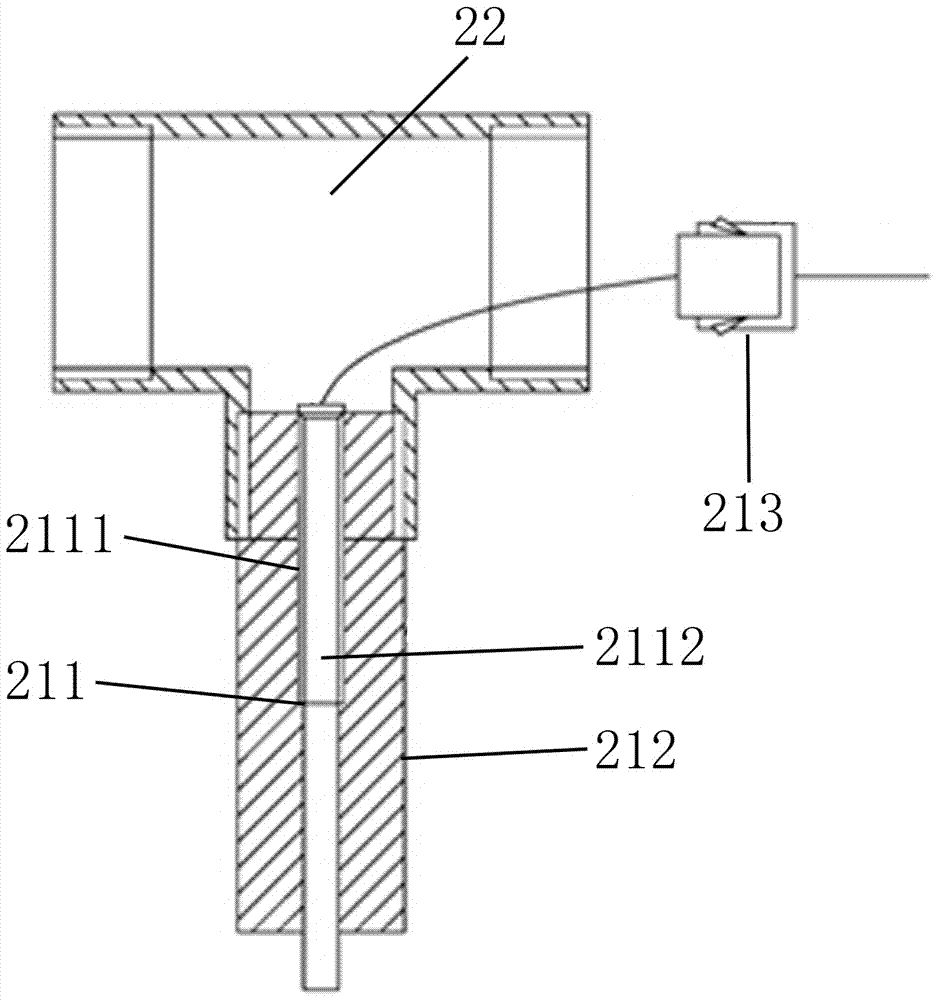

[0035] as attached figure 2 As shown, a plurality of temperature nodes 21 in the temperature data acquisition module 2 are connected to the main pipeline 23 through a tee 22. For the convenience of installation, the main pipeline 23 provided with sensors is connected through a flexible joint 25, and the top pipeline at the knuckle at the top of the retaining wall 11 24 (a metal hose) is connected with the main pipeline 23 through a self-fixing joint 26, and the multi-section main p...

Embodiment 2

[0038] Based on the method of the above-mentioned embodiment one monitoring system, the temperature data acquisition module 2 is used to detect the temperature information in the coal storage yard 1 in real time, and the data transmitting and receiving module 3 is based on ZigBee wireless communication technology, and the nodes communicating with each other send their own coordinate positions and temperature information Sent to the central node, the central node transmits the temperature data through the GPRS network to the remote server host computer software (data processing module 4) through the Zigbee to GPRS module, and the server-side host computer software processes the coal pile temperature data. The upper computer software has the overall layout of the coal yard and the layout of the measuring points, giving the operator an intuitive experience. The software can display the cloud map of the temperature of the entire coal yard in real time, and can also display the chang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com