Integrated High Power All Fiber Laser

An all-fiber and laser technology, which is applied to lasers, laser parts, phonon exciters, etc., can solve the problems of increasing the length of the transmission fiber of the fiber laser, increasing the volume of the high-power all-fiber laser, and reducing the integration of the fiber laser. Achieve the effects of easy maintenance and assembly, compact structure, and reduced time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

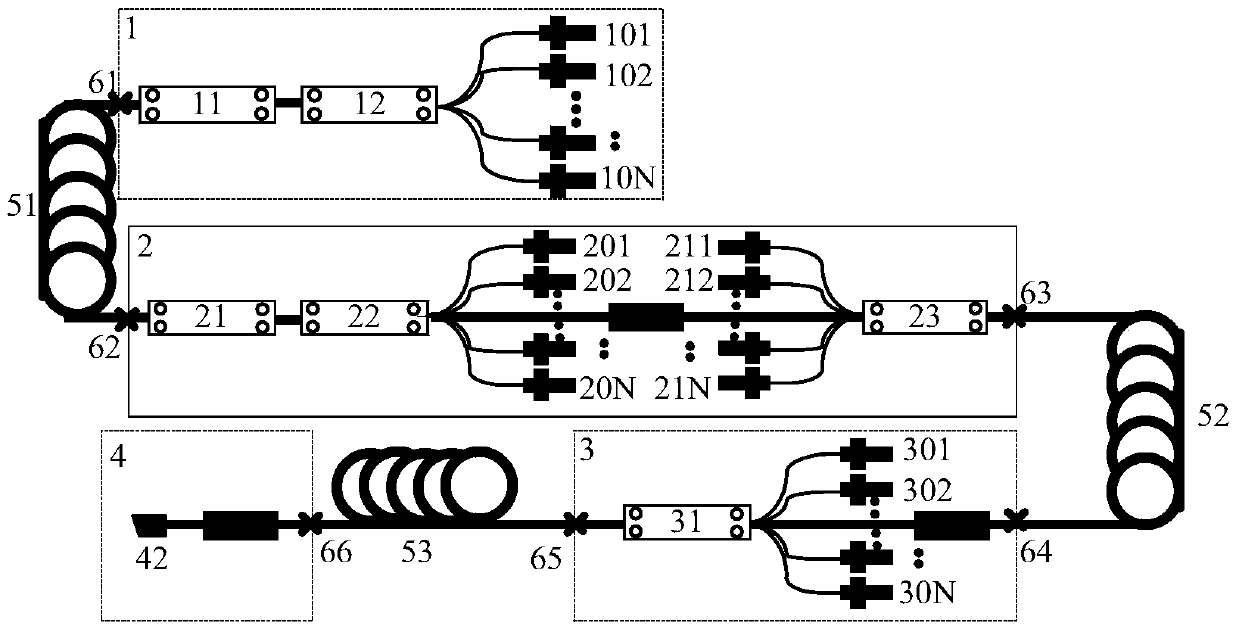

[0026] An integrated high-power all-fiber laser, characterized in that,

[0027] The left end of the first all-fiber device 1 is connected to the upper end of the first gain fiber 51 through the first melting point 61;

[0028] The lower end of the first gain fiber 51 is connected to the left end of the second all-fiber component 2 through the second melting point 62;

[0029] The right end of the second all-fiber component 2 is connected to the upper end of the second gain fiber 52 through the third melting point 63;

[0030] The lower end of the second gain fiber 52 is connected to the right end of the third all-fiber component 3 through the fourth melting point 64;

[0031] The left end of the third all-fiber component 3 is connected to the right end of the third gain fiber 53 through the fifth melting point 65;

[0032] The left end of the third gain fiber 53 is connected with the right end of the fourth all-fiber component 4 through the sixth melting point 66 .

[0033...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com