Ectopic leaching and screening interlock control system of soil and leaching screening method of system

An interlocking control and rinsing technology, which is applied in the field of rinsing systems, can solve the problems of small particles sticking to each other and high content of gravel, and achieve the effects of reducing pollution, increasing rinsing time, and controlling rinsing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

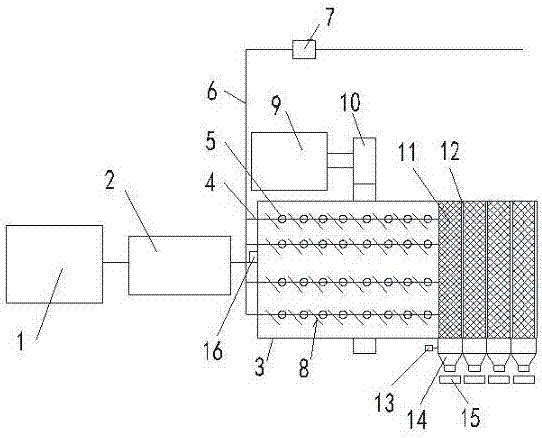

[0061] Such as figure 1 As mentioned above, the interlocking control system for ectopic soil rinsing and screening of the present invention includes a dispersing feeder 1, a weighing conveyor 2, a rinsing device, a screening device and a frequency conversion spraying pipeline. The dispersing feeder 1, the weighing conveyor 2 and the rinsing drum 3 in the rinsing device are sequentially connected. The bulk feeder 1 and the weighing conveyor 2 adopt existing equipment. The breaking feeder 1 is used to break up and push the soil to the weighing conveyor 2 . The weighing conveyor 2 is used to weigh and transport the loose soil with a low moisture content to the washing drum 3 . The weighing conveyor 2 can be a screw conveyor or a belt conveyor. The screening device is connected to the outlet end of the washing device. The frequency conversion spray pipeline is arranged in the rinsing drum 3 of the rinsing and screening device.

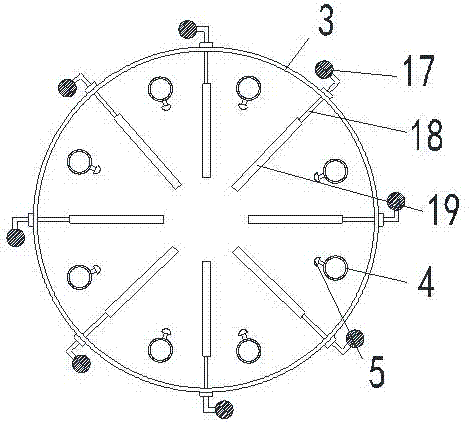

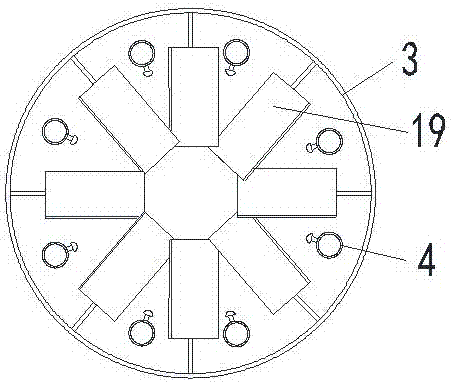

[0062] The rinsing device includes a rinsing dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com