Engineering bacteria and application thereof

A technology for engineering strains and genetically engineered bacteria, applied in the field of bioengineering, can solve the problems of high cost of racemic α-hydroxycarboxylic acid and expensive substrates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Construction of three-gene co-expression system.

[0043] (1) Primer design

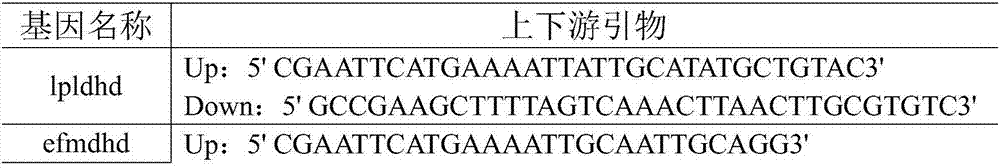

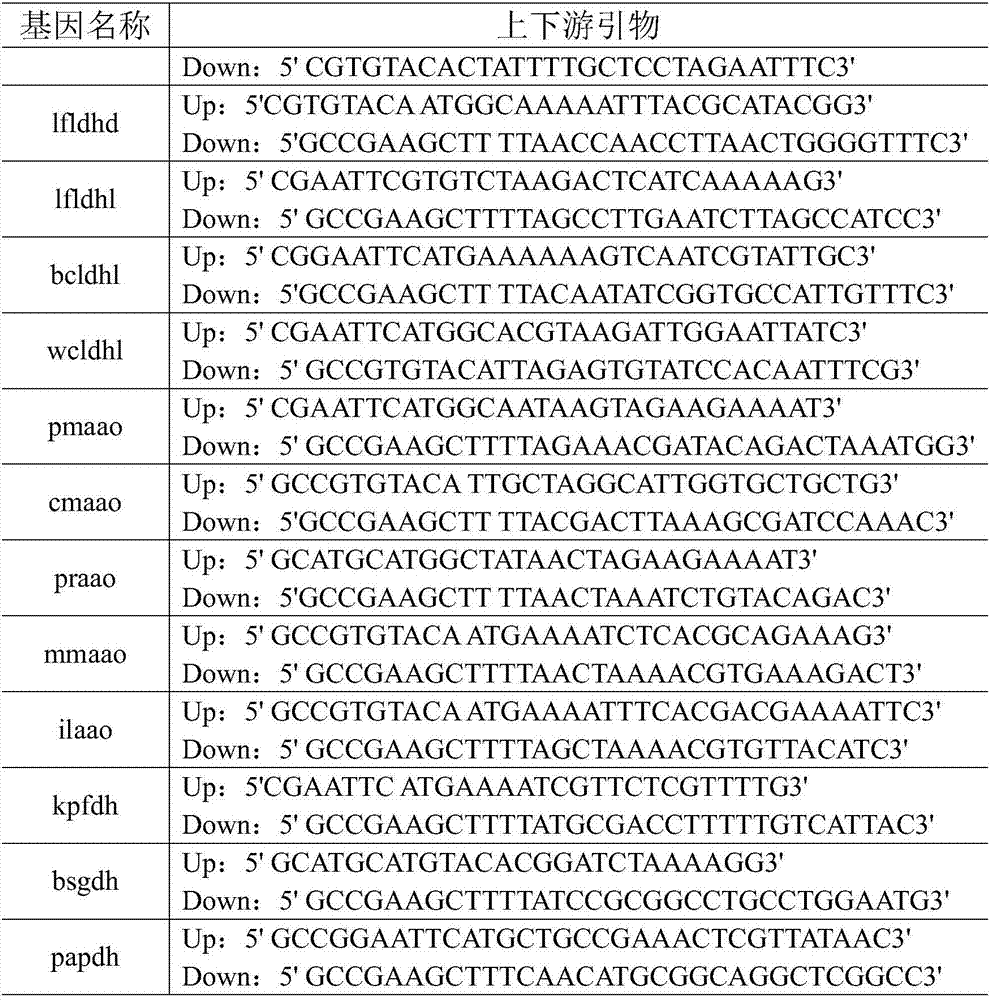

[0044] Design primers, the primer sequences are shown in Table 1

[0045] Table 1 Primers used for gene amplification

[0046]

[0047]

[0048] (2) PCR amplification

[0049]According to the instructions provided by the manufacturer, Genomic DNA Purification Kit (Takara) was used to extract the genomic DNA of the strains in logarithmic growth phase, and the primers in Table 1 were used for PCR amplification from the corresponding strains. Amplification system: PrimeSTAR HS DNA Polymerase (2.55U / μL) 0.5μL, 10×PrimeSTAR Buffer 10μL, dNTP Mixture (2.5mM each) 4μL, template DNA 1μL, Up primer (20μM) 1μL, Down primer (20μM) 1μL ,ddH 2 O to make up to 50 μL. The amplification program is: 94°C, 10min; 94°C, 30sec; 55°C, 30sec; 72°C, 2min, a total of 30 cycles; 72°C, 10min. PCR products were sent to Huada Genomics for confirmation.

[0050] From Lactobacillus plantarum ATCC 8041, Enteroc...

Embodiment 2

[0067] Induced expression of the genetically engineered bacteria obtained in Example 1.

[0068] Pick the single bacterium colony of genetically engineered bacteria that has been constructed and inoculate in 10mL LB medium (containing 0.1g / L ampicillin), cultivate at 37 ℃ for 12 hours, inoculate in LB medium (200mL of 1000mL shake flask liquid) at a volume ratio of 2%. , containing 0.1g / L ampicillin), continue to cultivate at 37°C for 2.5hr, until the bacterial logarithmic growth phase (OD 600 0.6-0.8), add IPTG to a concentration of 0.4mM, and culture at 20°C and 200rmp for 8h. After induction of expression, the cells were collected by centrifugation at 20° C., 8000 rpm, and 20 minutes. According to the amount of cells required for transformation, the number of shake flasks can be increased to obtain sufficient cells.

Embodiment 3

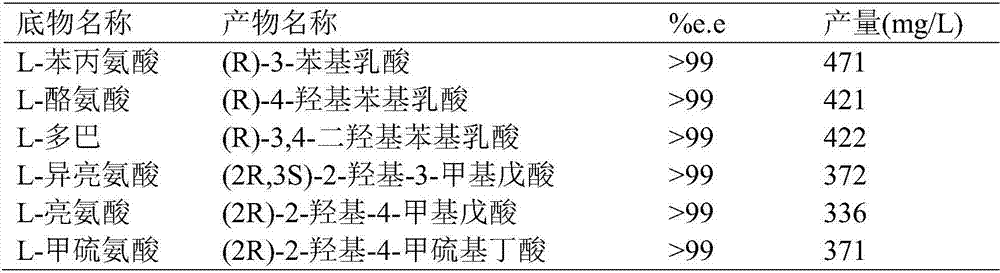

[0070] According to the induced expression method described in Example 2, the recombinant E. coli M15 / pQLinkN-cmaao-lpldhd-bsgdh was induced and expressed, and the bacterial cells were collected. In a reaction volume of 100ml, the transformation of different substrates mixed with whole cells was investigated. , the final concentration of the substrate is 0.5g / L, the glucose concentration is 10g / L, the pH is adjusted to 7.0, the weight of fresh whole cells is added to 20g (wet weight), the temperature is 30°C, and the results are measured after 24 hours of transformation. Various substrates The responses are shown in the table below.

[0071] Table 2 Transformation of different substrates by E. coli M15 / pQLinkN-cmaao-lpldhd-bsgdhcf

[0072]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com