Extracting method of bovine pituitary extract

An extraction method and extract technology, applied in the field of biomedicine, can solve the problems of low extraction efficiency, inability to large-scale production, complex extraction method, etc., and achieve the effects of high extraction efficiency, suitable for large-scale production, and saving pretreatment time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

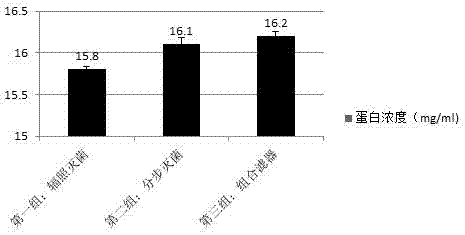

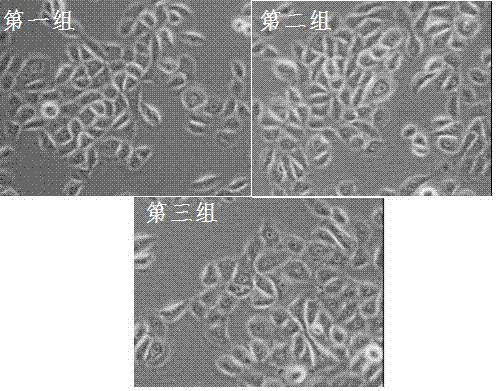

Embodiment 1

[0029] BPE extraction: Collect 40 fresh bovine pituitary glands, place them in RPMI-1640 medium, and transport them back to the operation room at low temperature. Brush with 4°C pre-cooled PBS for 3 to 5 times. After cleaning the blood stains, remove the external adhesion tissue and white fascia, expose the whole pituitary gland, then cut it into pieces with scissors, add PMSF with a final concentration of 10mmol / L, ultrasonic break, and ultrasonic The frequency is 300W, 5s / time, with an interval of 10s between each two times, until the tissue becomes a paste, and the diameter of the particles in the tissue does not exceed 0.05cm. Transfer the above treatment to a clean beaker, add 4°C pre-cooled PBS at a ratio of 1g / ml, then stir in a 4°C refrigerator at 300rpm for 150min, then transfer the mixture to a centrifuge tube, centrifuge at 8000rpm for 10min and collect The supernatant was subjected to secondary centrifugation at 10,000 rpm for 15 min, and the supernatant was collec...

Embodiment 2

[0031] BPE extraction: Collect 40 fresh bovine pituitary glands, place them in RPMI-1640 medium, and transport them back to the operation room at low temperature. Scrub with 4°C pre-cooled PBS for 3 to 5 times. After cleaning the blood stains, remove the external adhesion tissue and white fascia, expose the whole pituitary gland, then cut it into pieces with scissors, add PMSF with a final concentration of 50mmol / L, ultrasonic break, and ultrasonic The frequency is 500W, 5s / time, with an interval of 10s between each two times, until the tissue becomes a paste, and the diameter of the particles in the tissue does not exceed 0.05cm. Transfer the above treatment to a clean beaker, add 4°C pre-cooled physiological saline at a ratio of 2g / ml, then stir in a 4°C refrigerator at a speed of 300rpm for 100min, then transfer the mixture to a centrifuge tube, centrifuge at 6000rpm for 15min The supernatant was collected for secondary centrifugation at 10,000 rpm for 15 min, and the super...

Embodiment 3

[0033]BPE extraction: Collect 30 fresh bovine pituitary glands, place them in DMEM medium, and transport them back to the operation room at low temperature. Brush with 4°C pre-cooled PBS for 3 to 5 times. After cleaning the blood stains, remove the external adhesion tissue and white fascia, expose the whole pituitary gland, add PMSF with a final concentration of 100mmol / L, and then use a homogenizer at 2000rpm, Start for 3 seconds for the first time, and perform jogging and crushing at intervals of 1-2 seconds until the tissue becomes a paste, and the diameter of the particles in the tissue does not exceed 0.05cm. Transfer the above treatment to a clean beaker, add 4°C pre-cooled PBS at a ratio of 0.3g / ml, then stir in a 4°C refrigerator at a speed of 400rpm for 90min, then transfer the mixture to a centrifuge tube, and centrifuge at 6000rpm for 10min The supernatant was collected for secondary centrifugation at 13000 rpm for 10 min, and the supernatant was collected. Use a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com