Coding beam-splitting phase measurement device and method

A technology of phase measurement and beam splitting, which is applied in measurement devices, measurement optics, optical radiation measurement, etc., can solve problems such as low measurement resolution, limited number of Hartmann sensor array units, and high price of interferometers. High signal-to-noise ratio, simple structure and data recording process, and high-resolution effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the protection scope of the present invention should not be limited thereby.

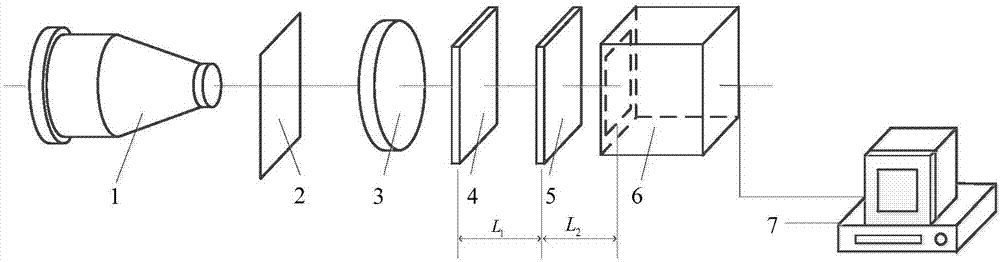

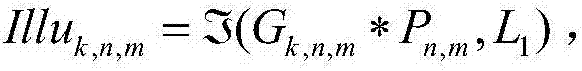

[0040] see first figure 1 , figure 1It is a schematic diagram of the encoding beam splitting phase measuring device of the present invention. It can be seen from the figure that a coded beam-splitting phase measurement device of the present invention includes: a beam reducer 1, an incident plane 2, a lens 3, and a diffraction grating 4 with known order distribution along the propagation direction of the incident light of the beam to be measured. , distribution known diffraction sample 5, spot detector 6 and computer 7, described incident plane 2 is positioned at described lens 3 front 2 times of focal length place, the target surface of described spot detector 5 and described The distance of the lens 3 is 2 times the focal length, the diffraction grating 4 is placed betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com