Lithium iron phosphate anode slurry stirring technology

A lithium iron phosphate and stirring process technology, applied in electrode manufacturing, battery electrodes, nanotechnology for materials and surface science, etc., can solve the problems of poor dispersibility and poor consistency of lithium iron phosphate cathode slurry, and achieve consistency Excellent, good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

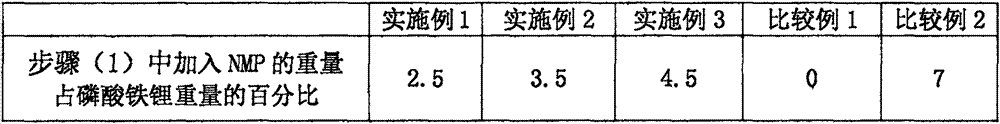

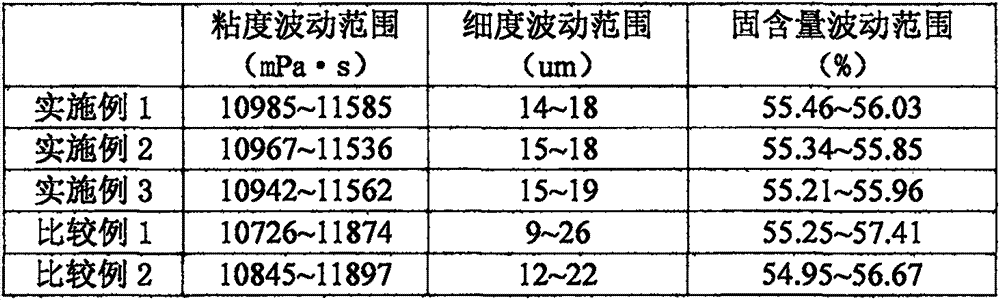

Embodiment 1

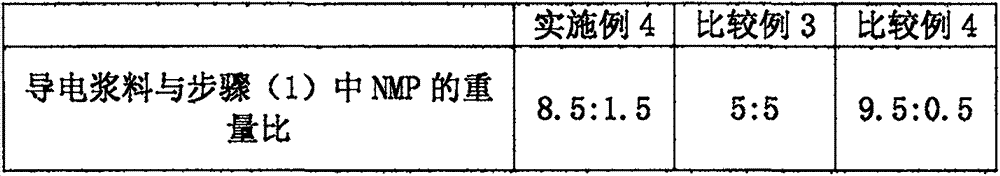

[0033] A lithium iron phosphate positive electrode slurry is prepared according to the following stirring process, which process includes:

[0034] (1) Add 75kg of conductive paste (6% solid content) and 8.75kg of NMP into the mixing tank; (2) Add 17kg of PVDF into the mixing tank, set the stirring speed to 15Hz, the dispersion speed to 400 rpm, and stir for 50min; (3) Add 350kg of lithium iron phosphate and 4kg of conductive carbon black, set the stirring speed to 30Hz, and disperse at 800 rpm, and dry mix for 150min; (4) Add 180kg of NMP, set the stirring speed to 30Hz, and the dispersion speed When the temperature is 1200 rpm, stir for 120min; (5) reverse defoaming, set the stirring speed to 15Hz, and stir for 30min; (6) detect the viscosity value of the slurry is 7000-13000mPa·s, and the fineness of the slurry is ≤30um , the solid content is 50-65%, and the slurry preparation is completed.

Embodiment 2

[0036] The difference from Example 1 is that the amount of NMP added in the step (1) is 12.25kg.

Embodiment 3

[0038] Different from Example 1, the amount of NMP added in the step (1) is 15.75kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity value | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com