Nitrogen-rich porous material preparation method and application of nitrogen-rich porous material to recovery of precious metals in circuit board

A technology of porous materials and circuit boards, which is used in chemical instruments and methods, other chemical processes, and the improvement of process efficiency to achieve the effect of protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

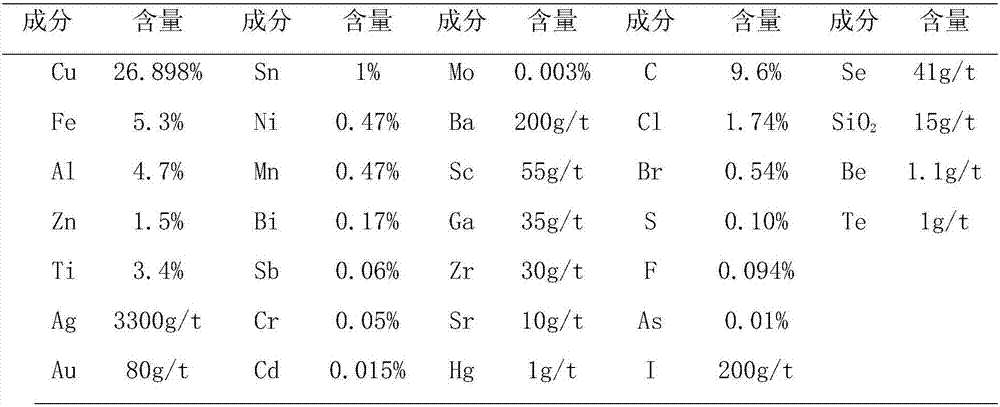

Problems solved by technology

Method used

Image

Examples

Embodiment 1

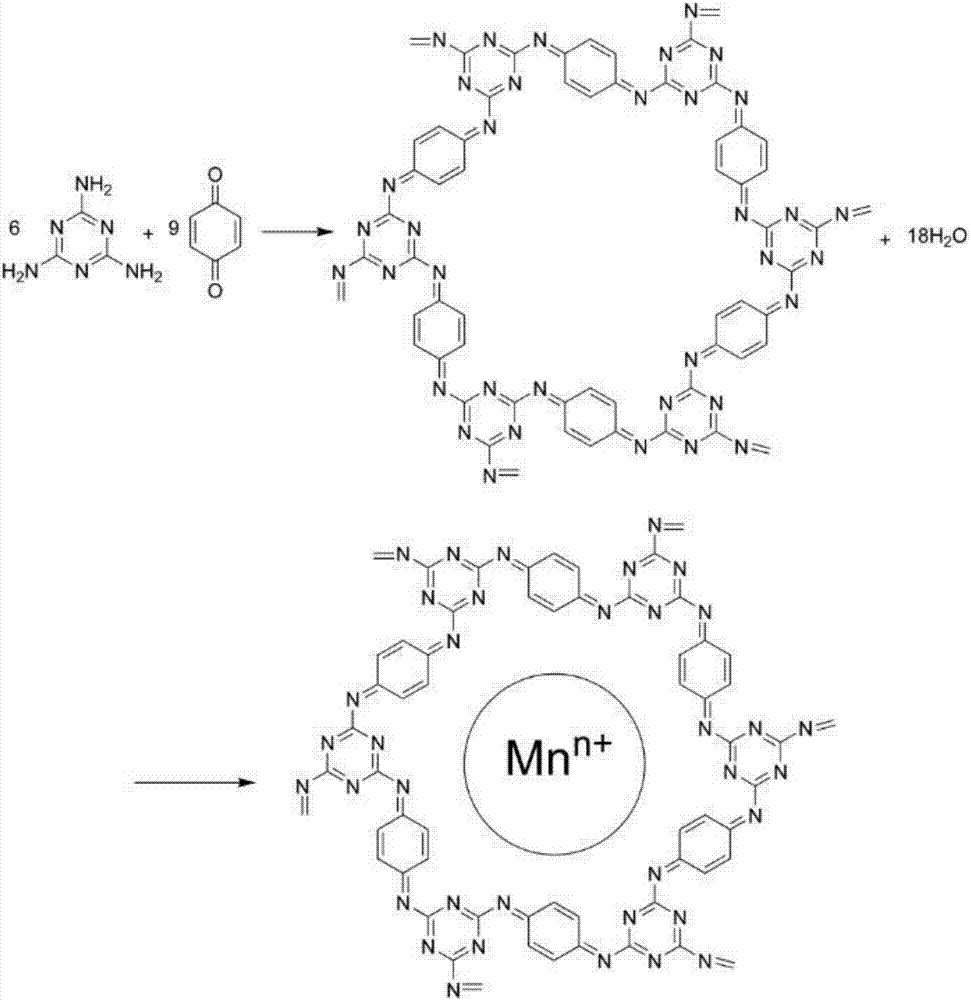

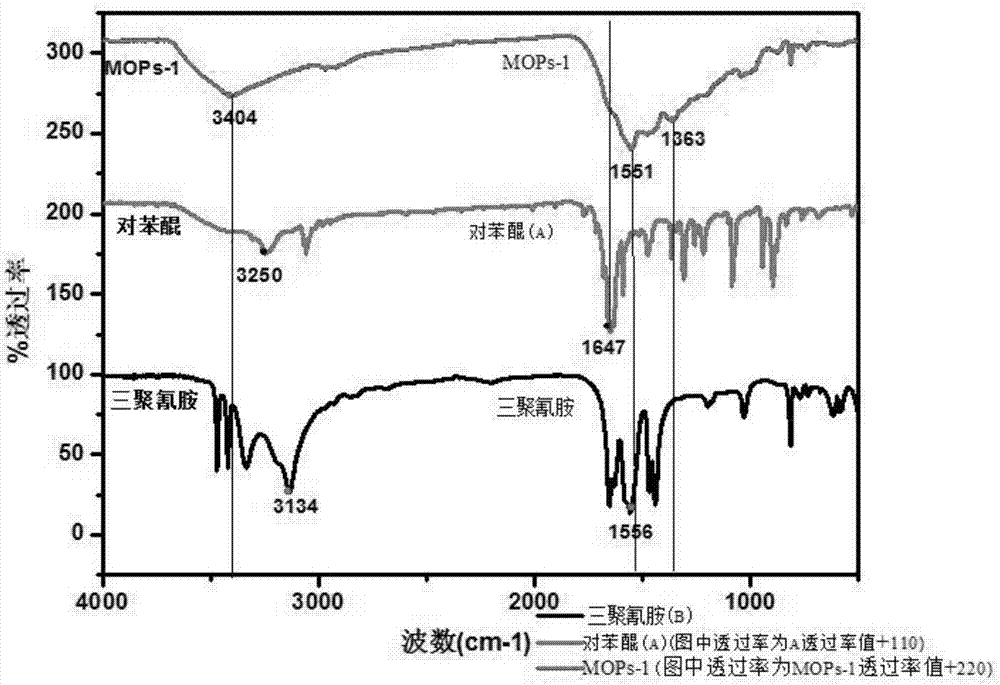

[0038] In 1L of ethylene glycol, add 0.20mol of melamine and 0.30mol of p-benzoquinone, heat, stir, keep the temperature stable at 180°C for 5 hours, add 300mL of xylene, install a water separator, and set the temperature at 136-140°C for 5 hours The toluene was refluxed to take away the water, polycondensed for 4 hours, stopped stirring, naturally cooled to room temperature, filtered to obtain a brown precipitate, washed three times with 100 mL of ethanol, and dried in vacuum at 80°C to obtain 40.5 g of a brown blocky solid with a yield of 86.5%.

Embodiment 2

[0040] In 1L of ethylene glycol, add 0.19mol of melamine and 0.30mol of p-benzoquinone, heat and stir, keep the temperature stable at 180°C for 5 hours, add 300mL of xylene, install a water separator, and set the temperature at 136-140°C Toluene was refluxed to take away water, polycondensed for 4 hours, stopped stirring, naturally cooled to room temperature, filtered to obtain a brown precipitate, washed three times with 100 mL of ethanol, and dried under vacuum at 80°C to obtain 35.6 g of a brown solid with a yield of 80.1%.

Embodiment 3

[0042] In 1L of ethylene glycol, add 0.22mol of melamine and 0.30mol of p-benzoquinone, heat, stir, keep the temperature stable at 180°C for 5 hours, add 300mL of xylene, install a water separator, and set the temperature at 136-140°C Toluene was refluxed to take away water, polycondensed for 4 hours, stopped stirring, naturally cooled to room temperature, filtered to obtain a brown precipitate, washed three times with 100 mL of ethanol, and dried in vacuum at 80°C to obtain 40.2 g of a brown solid with a yield of 85.9%.

[0043] It can be seen from Examples 1-3 that when the molar ratio of melamine to p-benzoquinone is 1.9-2.2:3, the reaction yield is higher. According to the molar ratio of melamine and p-benzoquinone being 2:3, it will be further elaborated in the examples.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com