Box body sanding machine

A technology of grinding machine and grinding mechanism, which is applied in the direction of grinding frame, grinding machine, abrasive belt grinding machine, etc., can solve the problems of laborious grinding, low processing efficiency, high work-related injury rate, etc., achieve good grinding effect, improve grinding efficiency, and ensure The effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below.

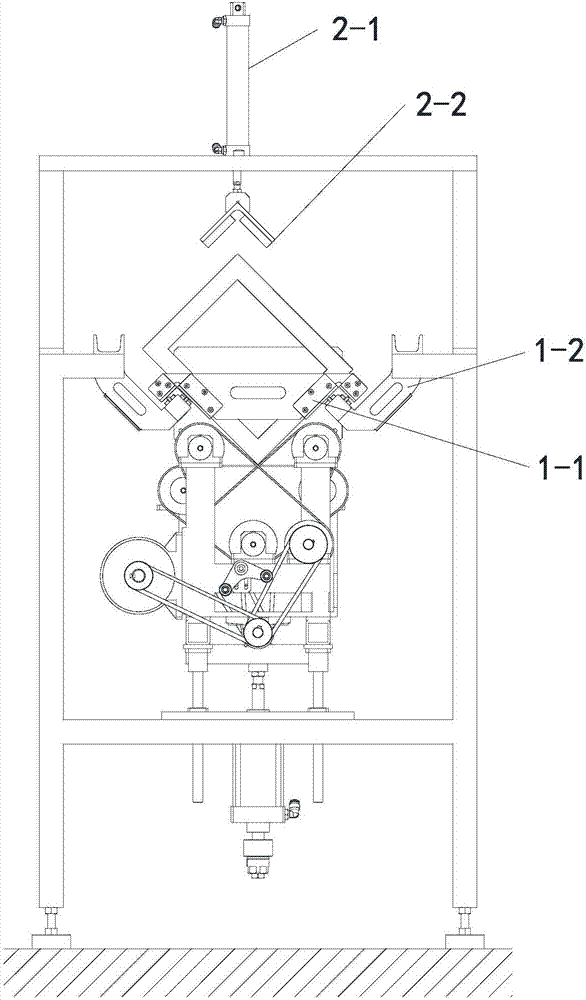

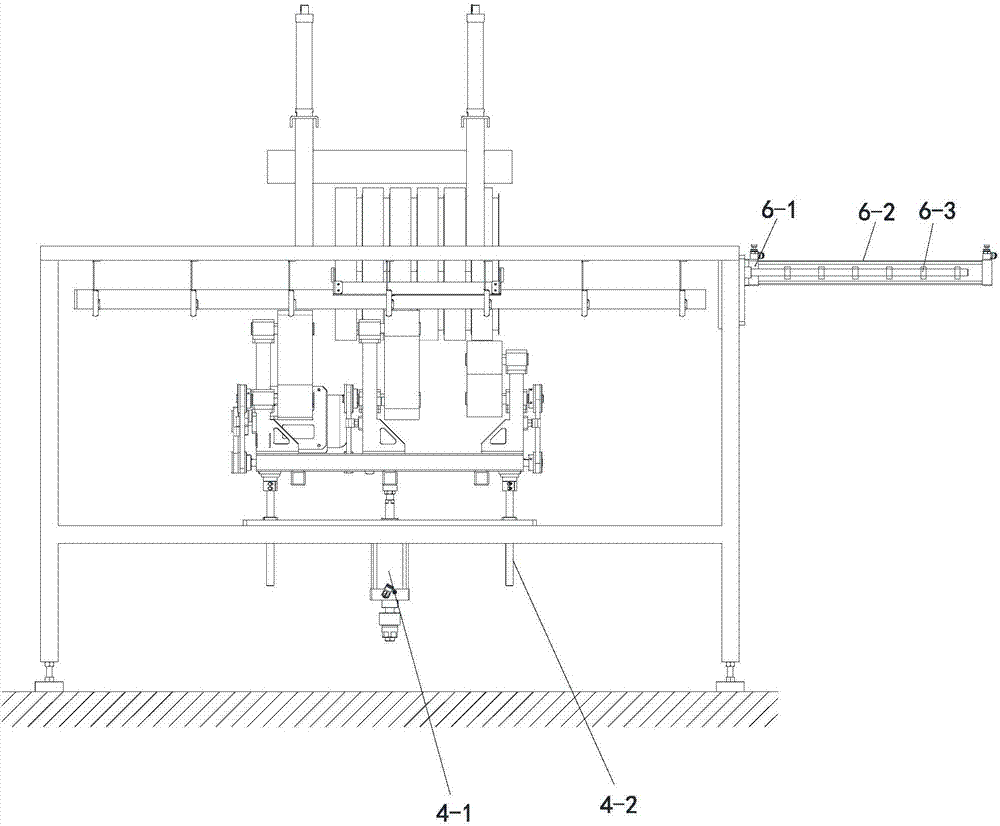

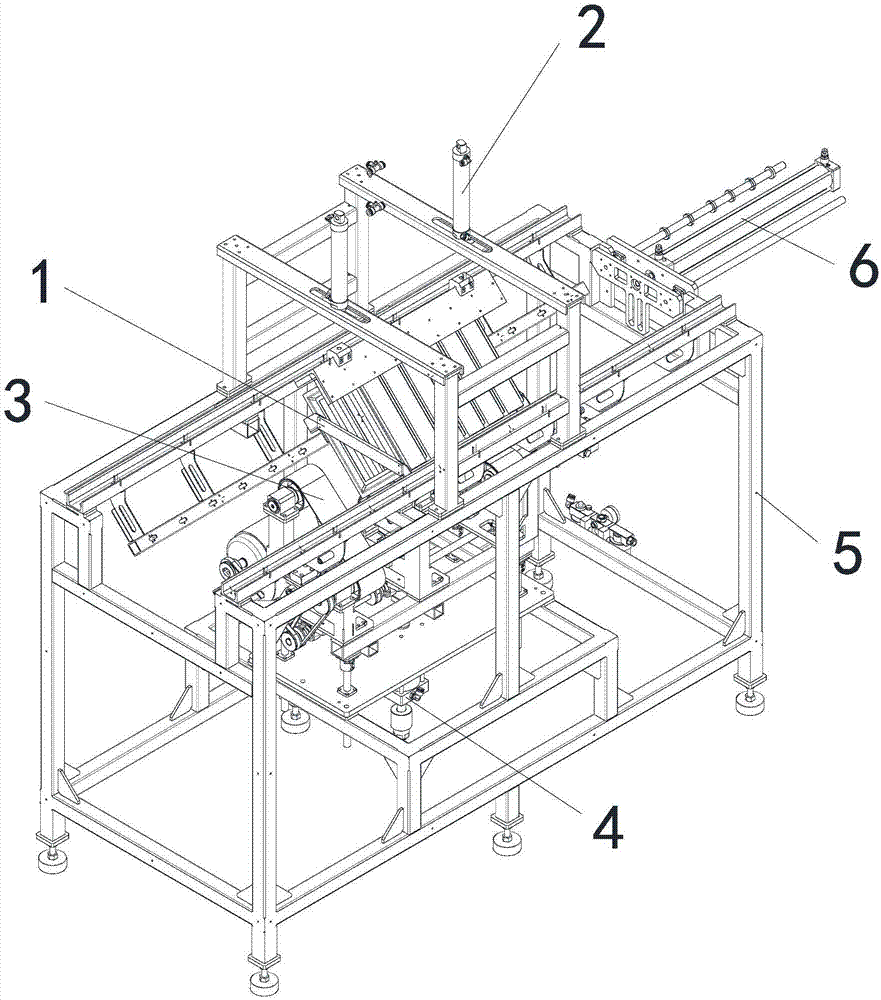

[0031] The box grinding machine includes a box supporting mechanism, a pressing mechanism, an abrasive belt grinding mechanism, an up and down translation mechanism, a frame, and a pushing mechanism for pushing the box forward. The box with the side to be polished facing downward is fixed on the frame through the box support mechanism, and the pressing mechanism compresses the box from above; the abrasive belt grinding mechanism moves up and down on the frame through the up and down translation mechanism to approach or leave the box; The pushing mechanism is installed at the rear end of the frame.

[0032] In this embodiment, six boxes are placed in one workpiece placement jig, and multiple workpiece placement jigs can be placed in sequence between the two V-shaped rails.

[0033] The box support mechanism includes a workpiece placing fixture and two V-shaped rails; the V-shaped rail extends along the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com