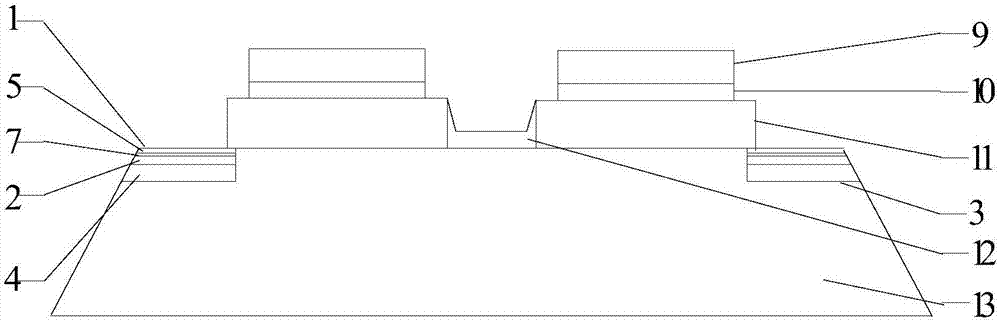

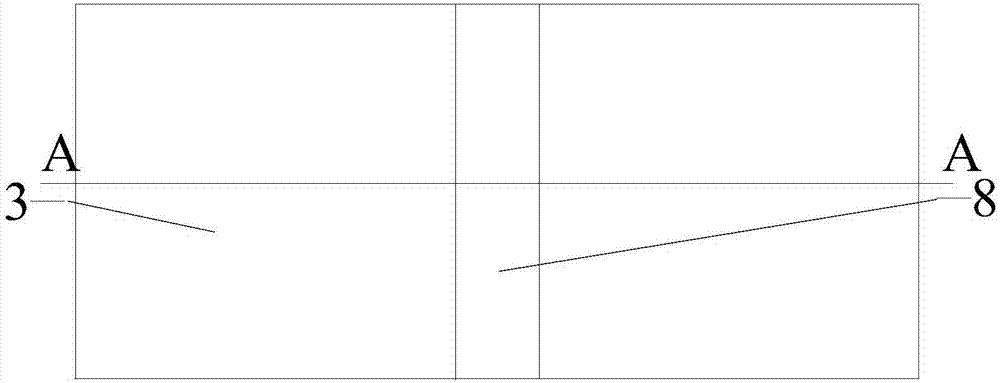

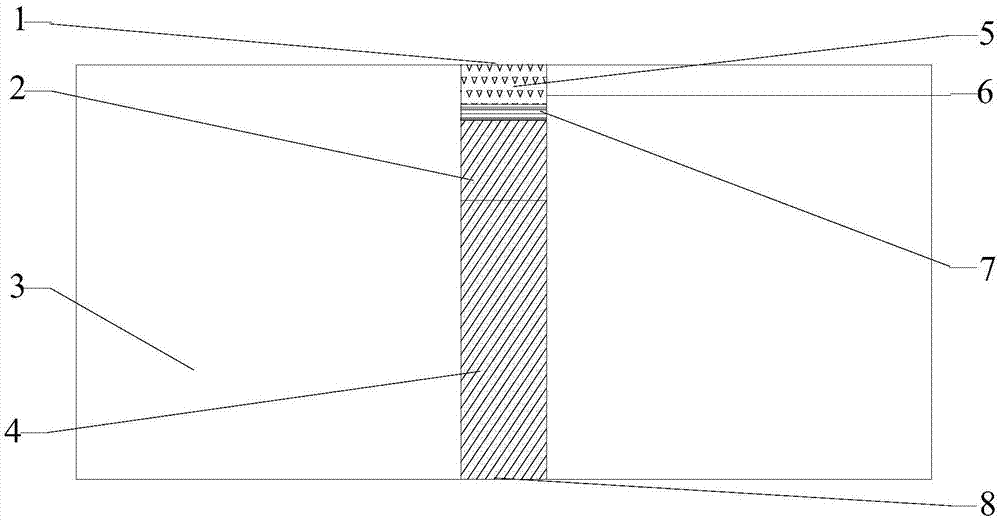

Leakproof structure for waterproof-layer expansion joints in cold-region high-speed railway trackless-track subgrade surface

A high-speed railway and sealing structure technology, applied in the direction of roads, tracks, buildings, etc., can solve the problems of low freeze-thaw resistance, low durability, weak interface adhesion, etc., and achieve strong chemical activity and adhesion, waterproof and waterproof. Good sealing effect and strong durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The sealing structure of the present invention for the expansion joint of the waterproof layer of the subgrade surface of the high-speed railway ballastless track in cold regions will be described in detail below in conjunction with specific embodiments.

[0033] Various materials used in the present invention are commercially available. In the following specific examples:

[0034] The epoxy resin grouting material adopts EPX epoxy resin grouting material produced by Shanghai Tunnel Building Waterproof Material Co., Ltd.

[0035] The nano-silane gel material adopts PERTEX31 nano-silane gel material produced by Tianjin Keyi Xinyida Technology Development Co., Ltd.

[0036] The nano-silica waterproof coating adopts Yizhong 986 nano-silica waterproof coating produced by Tianjin Keyi Xinyida Technology Development Co., Ltd.

[0037] The polyacrylamide dispersant adopts PA2100 polyacrylamide dispersant produced by Shanghai Puyi Environmental Protection Technology Developme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com