Anti-fatigue damage element-replaceable assembled composite beam and construction method

An anti-fatigue damage, prefabricated technology, applied in the direction of erecting/assembling bridges, bridges, bridge parts, etc., can solve the problems of self-heavy, repair workload and long time, to improve construction efficiency, shorten construction period, and reduce maintenance costs and the effect of risks during use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

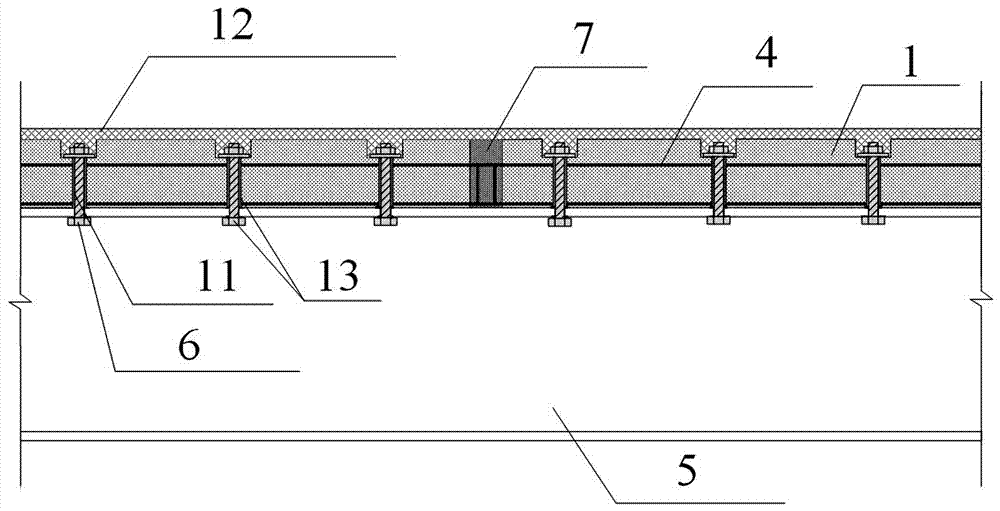

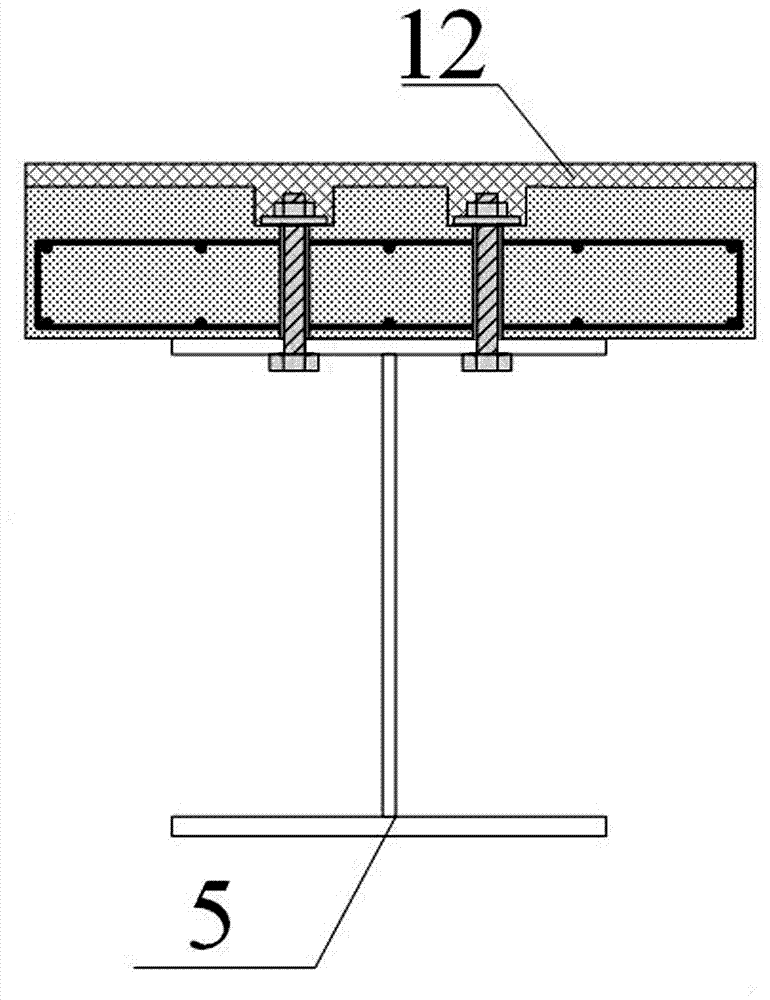

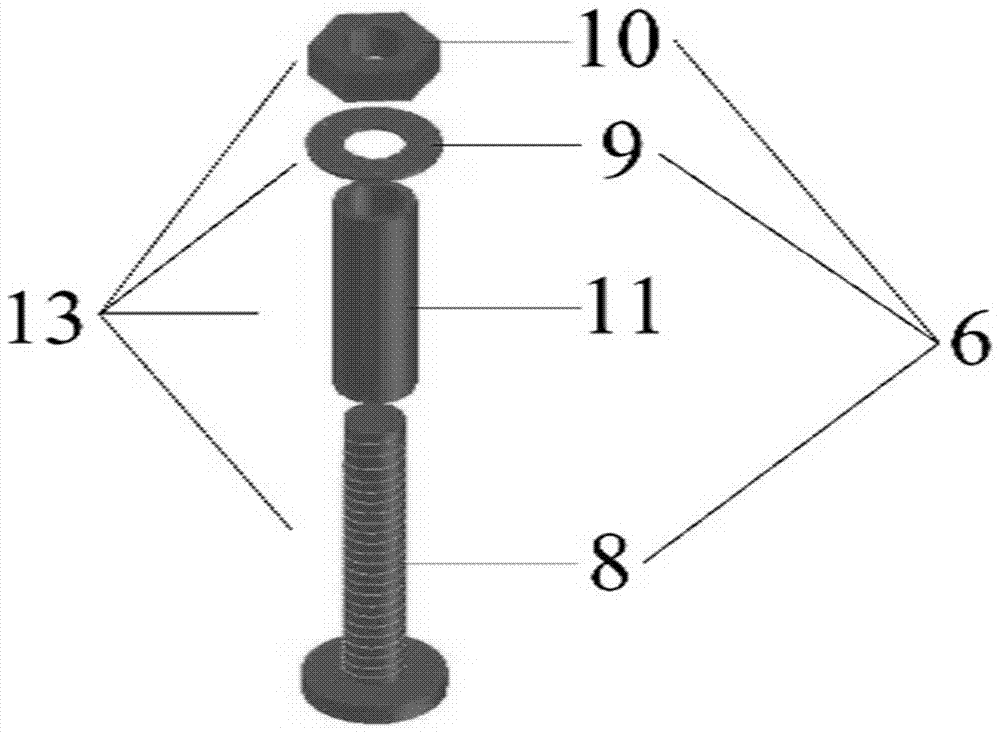

[0024] An assembled composite beam that can replace the anti-fatigue damage element, such as figure 1 , figure 2 , image 3 As shown, it includes a main structure, an anti-fatigue damage element 13 and a bridge deck pavement 12; the main structure includes a prefabricated high-performance concrete bridge deck 1, a high-strength steel beam 5, and a concrete post-cast belt 7; the anti-fatigue damage element 13 It includes a friction type high-strength bolt pair 6 and a rubber sleeve 11; the friction type high-strength bolt pair 6 includes a friction type high-strength bolt rod 8, a washer 9 and a nut 10; the prefabricated high-performance concrete bridge deck 1 is provided with reserved bolts Hole 3, the bolt hole 14 is reserved on the upper flange of the high-strength steel beam 5; the friction-type high-strength bolt rod 8 passes through the bolt hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com