A flat plate resistance testing device for experiment

A test device, flat plate resistance technology, which is applied in the field of experimental flat plate resistance test device, can solve the problems of small measuring range, error, and affecting the accuracy of measurement results, etc., and achieve the effect of reducing measurement error and appropriate measuring range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

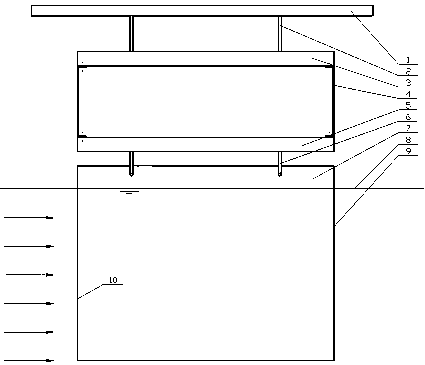

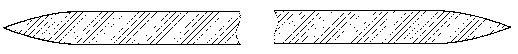

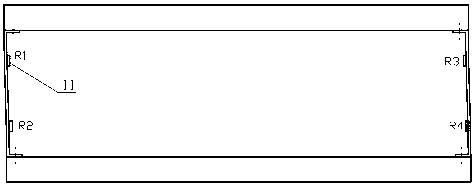

Embodiment 1

[0034] A test device for the resistance of an experimental flat plate, the test device comprising three parts of an experimental stand, a dynamometer and an experimental plate installed sequentially from top to bottom, the dynamometer, the experimental stand and the experimental plate are all connected by a hook; The width of the dynamometer is not less than the width of the experimental plate; the length of the experimental plate is a thin steel plate with a length of 1000 mm, a width of 700 mm, and a thickness of 4 mm to reduce wave resistance. The experimental flat plate is vertically hoisted on the lower end of the dynamometer in a two-point hoisting manner, so as to avoid the deformation of the experimental flat plate under the action of gravity and the occurrence of hydrodynamic excitation. The hoisting position is 25% away from the leading edge and the trailing edge of the experimental plate, that is, 50mm. The lower end of the experimental plate is immersed below the wat...

Embodiment 2

[0042] A test device for the resistance of an experimental flat plate, the test device includes three parts: an experimental stand, a dynamometer and an experimental plate installed from top to bottom. The dynamometer, the experimental stand and the experimental plate are all connected by a lifting ring; The width of the dynamometer is not less than the width of the experimental plate; the length of the experimental plate is a thin steel plate with a length of 2000 mm, a width of 1500 mm, and a thickness of 8 mm to reduce wave making resistance. The experimental plate is vertically hoisted on the lower end of the dynamometer in a two-point hoisting manner, so as to avoid the deformation of the experimental plate under the action of gravity and the occurrence of hydrodynamic excitation. The hoisting position is at a distance of 20% of the length of the pilot and follow-up test plates, that is, 400mm. The lower end of the test plate is immersed below the water surface; the leading...

Embodiment 3

[0044] A test device for the resistance of an experimental flat plate, the test device comprising three parts of an experimental stand, a dynamometer and an experimental plate installed sequentially from top to bottom, the dynamometer, the experimental stand and the experimental plate are all connected by a hook; The width of the dynamometer is not less than the width of the test plate; the test plate has a length of 500mm, a width of 300mm, and a thin steel plate with a thickness of 3mm to reduce wave resistance. The experimental plate is vertically hoisted at the lower end of the dynamometer in a two-point hoisting manner, so as to avoid the deformation of the experimental plate under the action of gravity and the occurrence of hydrodynamic excitation. The hoisting position is 15% away from the leading edge and the trailing edge of the experimental plate, which is 75mm. The lower end of the experimental plate is immersed below the water surface; the leading edge and trailing e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com