Low smoke zero halogen flame resistant cable

A fire-resistant cable and fire-resistant layer technology, which is applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of low temperature resistance of insulating layers and sheaths, and achieve good flame-retardant effects, long escape time, and long burning time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

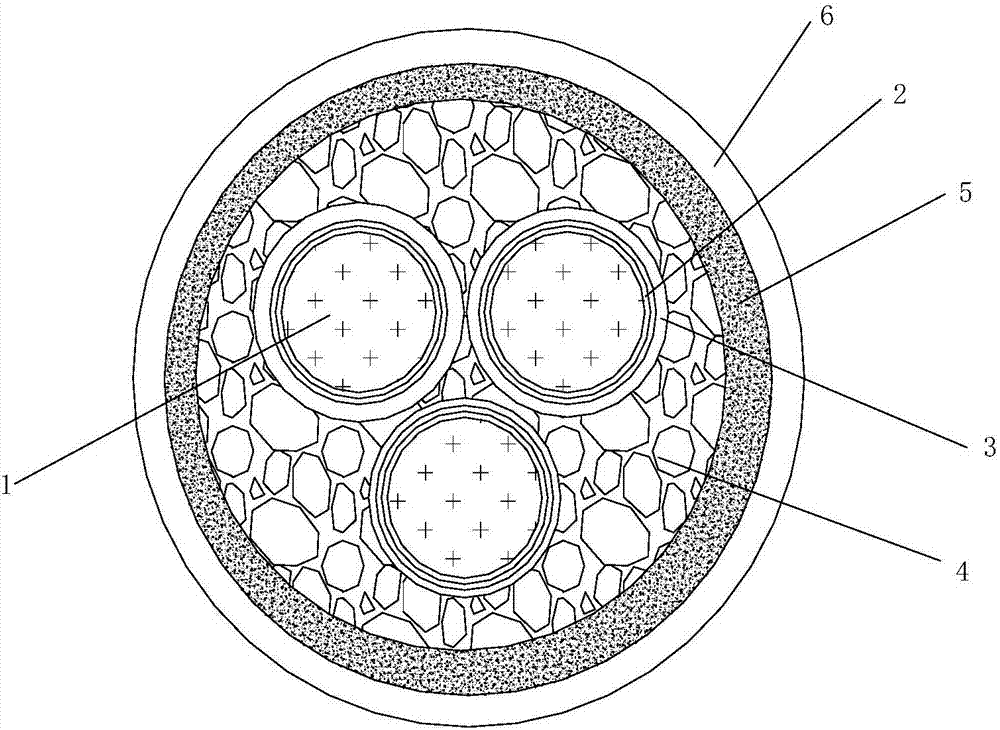

[0009] Such as figure 1 As shown, the present invention provides a low-smoke, halogen-free, fire-resistant cable, which includes a cable body, and the cable body includes a multi-strand twisted wire core, a halogen-free flame-retardant tape 5 and a halogen-free, low-smoke, flame-retardant polyolefin outer shell. Sheath 6, the wire core includes conductor 1, two layers of mica refractory layer 2 and low-smoke halogen-free polyolefin insulation layer 3, the mica refractory layer 2 is wrapped around the conductor 1, and the low-smoke halogen-free polyolefin insulation layer 3 is extruded on Outside the mica refractory layer 2; the wire core is wrapped in the halogen-free flame-retardant tape 5, and the gap between the wire core and the halogen-free flame-retardant tape 5 is filled and extruded with ceramizable halogen-free polyolefin 4, and the halogen-free flame-retardant tape 5 Outer sheath 6 of halogen-free low-smoke flame-retardant polyolefin outer sheath.

[0010] In the ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com