6-nitro-1, 2-diazooxy-4-naphthalene sulfonate acidification material washing kettle tail gas purification device

An exhaust gas purification and treatment device technology, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve problems such as increased production cost, exhaust emission resistance, complex exhaust gas composition, etc., to reduce overall costs and reduce the use of reagents Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

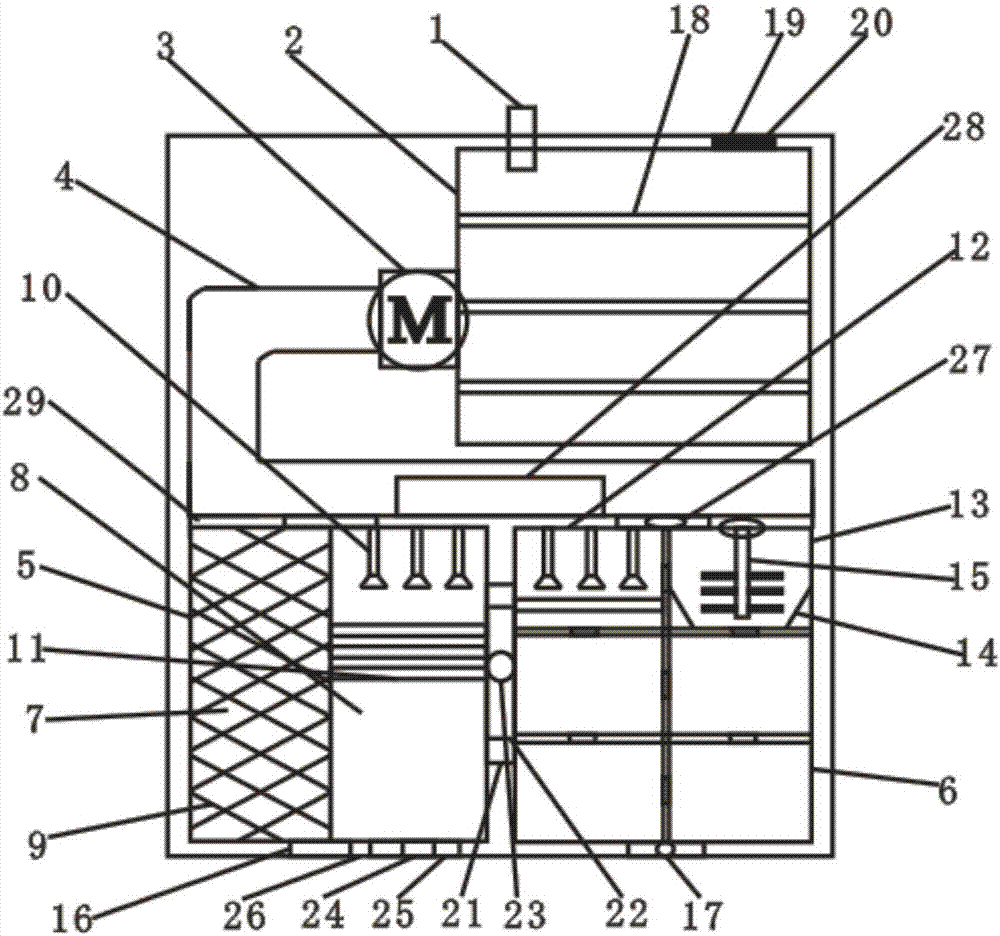

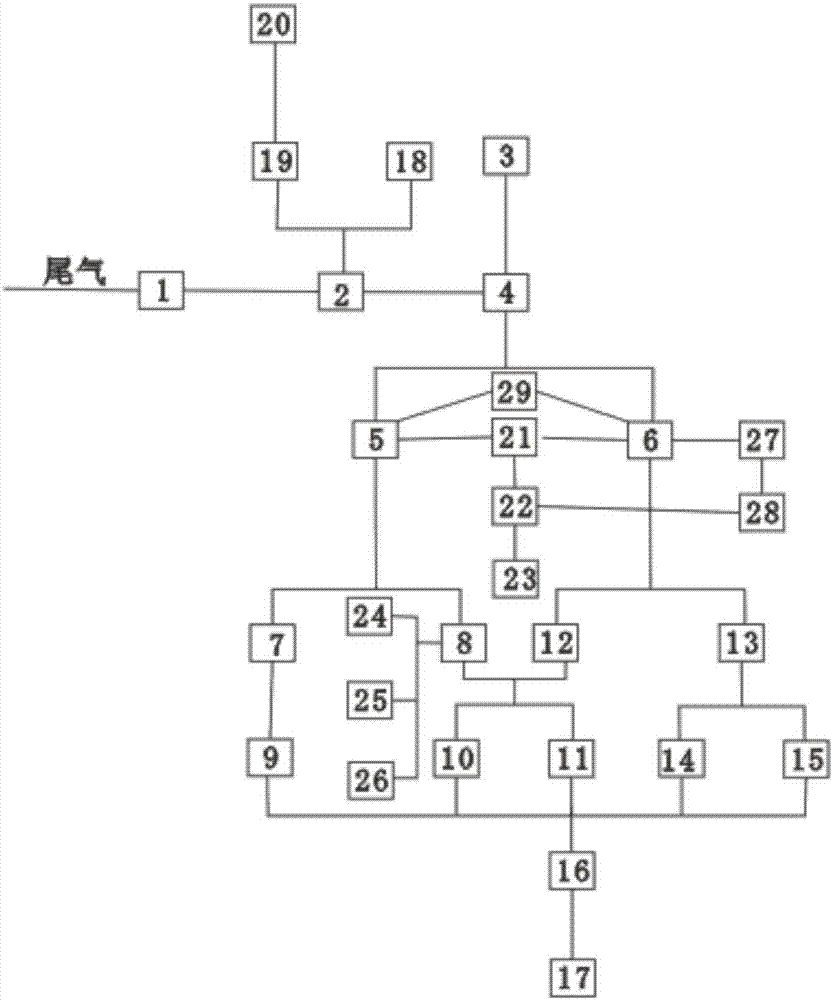

[0022] A kind of nitrate body acidification washing tank tail gas purification treatment device, comprises air inlet 1, and described air inlet 1 is the inlet that tail gas enters purification treatment device, and described air inlet 1 is connected with buffer gas storage tank 2, and described The function of the buffer gas storage tank 2 is to reduce the speed, temperature and pressure of the tail gas entering the air inlet at high speed. A series of capillary heat collectors 18 are fixedly installed on the outer surface of the buffer gas storage tank 2. There is a pressure relief hole 19 on the top of the tank. The capillary heat collection tube 18 gathers and gathers the heat that has just entered the exhaust gas naturally dissipated, and the pressure relief hole 19 releases the pressure that has entered the buffer gas storage tank 2. To the outside world, an air collection fan 3 and an air guide pipe 4 are installed on the side of the buffer gas storage tank 2, and the air...

Embodiment 2

[0032] For the embodiment 2 shown in the figure, the difference from the embodiment 2 is that the critical pressure value of the pressure semi-permeable membrane 20 is 0.55715 MPa.

Embodiment 3

[0034] For the embodiment 2 shown in the figure, the difference from the embodiment 2 is that the critical pressure value of the pressure semi-permeable membrane 20 is 1.013 MPa.

[0035] Based on the above, the advantage of the present invention is that, through the application of the buffer gas storage tank, the pressure can be released and dissipated in time, and the residual heat can be stored through the heat collection function of the capillary heat collector, and the temperature and pressure can be lowered without affecting normal production. The follow-up treatment provides a good foundation, and optimizes the treatment route through component analysis, and processes the exhaust gas through the physical treatment room and the chemical treatment room respectively according to the actual components. Raw materials, reduce the use of reagents as much as possible, and reduce the overall cost. After multiple treatments, the gas quality test is carried out, and it is discharge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com