All-direction wheel type movable heavy casting robot

A robot and wheeled technology, applied in foundry workshops, foundry equipment, manipulators, etc., can solve the problems of high labor intensity, small working range, and limited movement of workers, so as to reduce labor intensity and production costs, and improve movement flexibility , Improve the effect of support stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

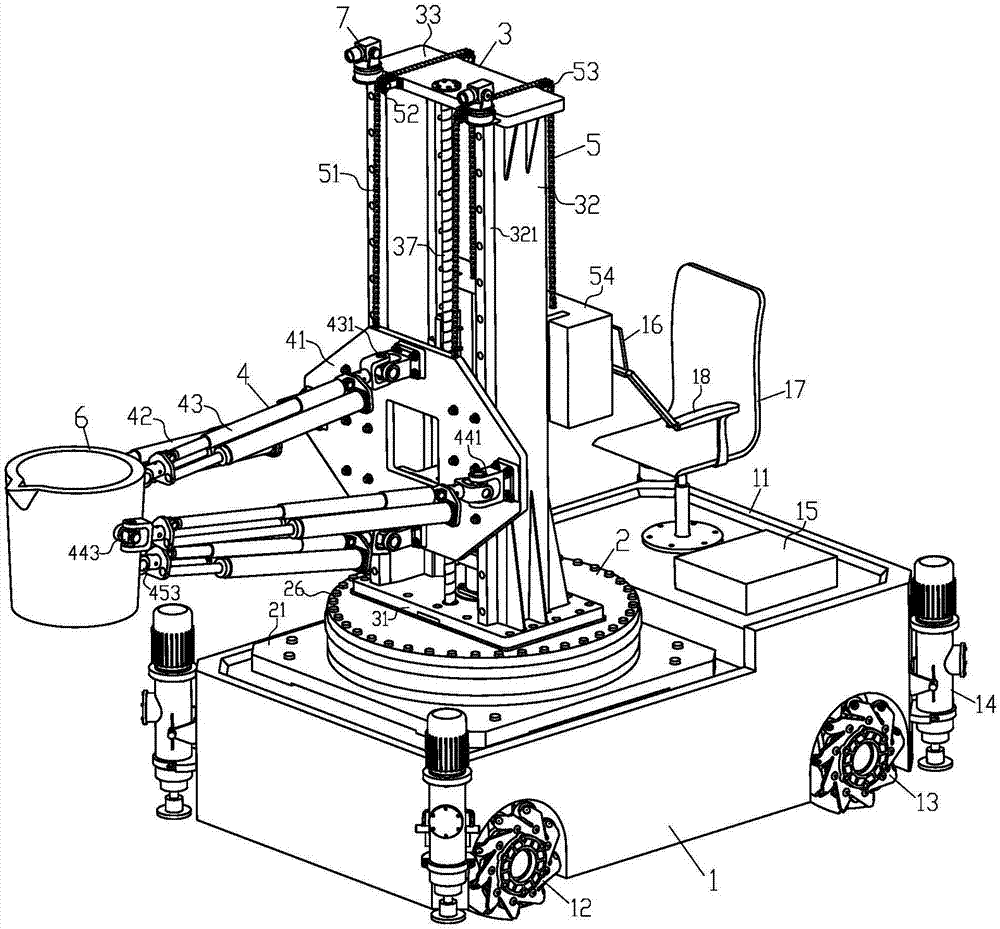

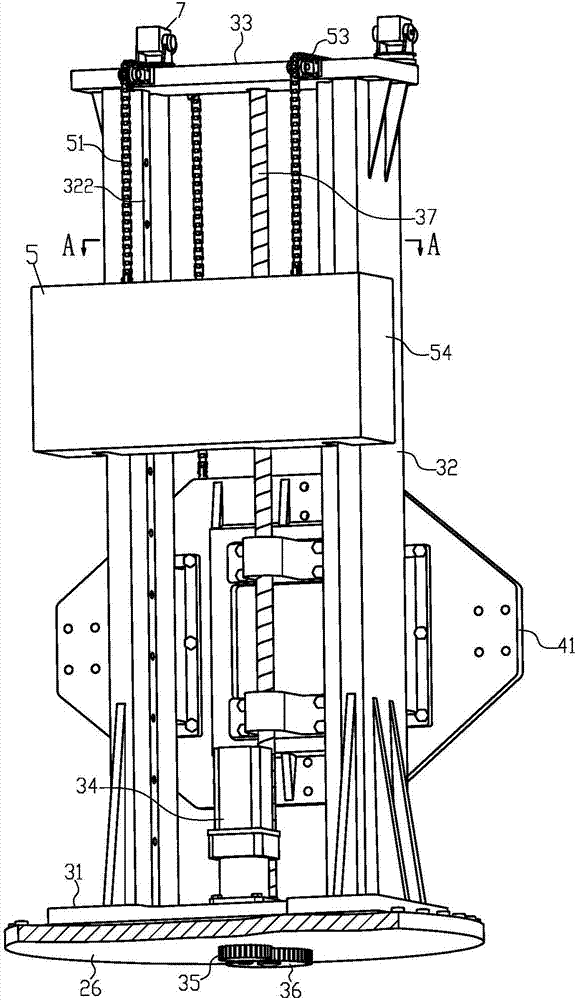

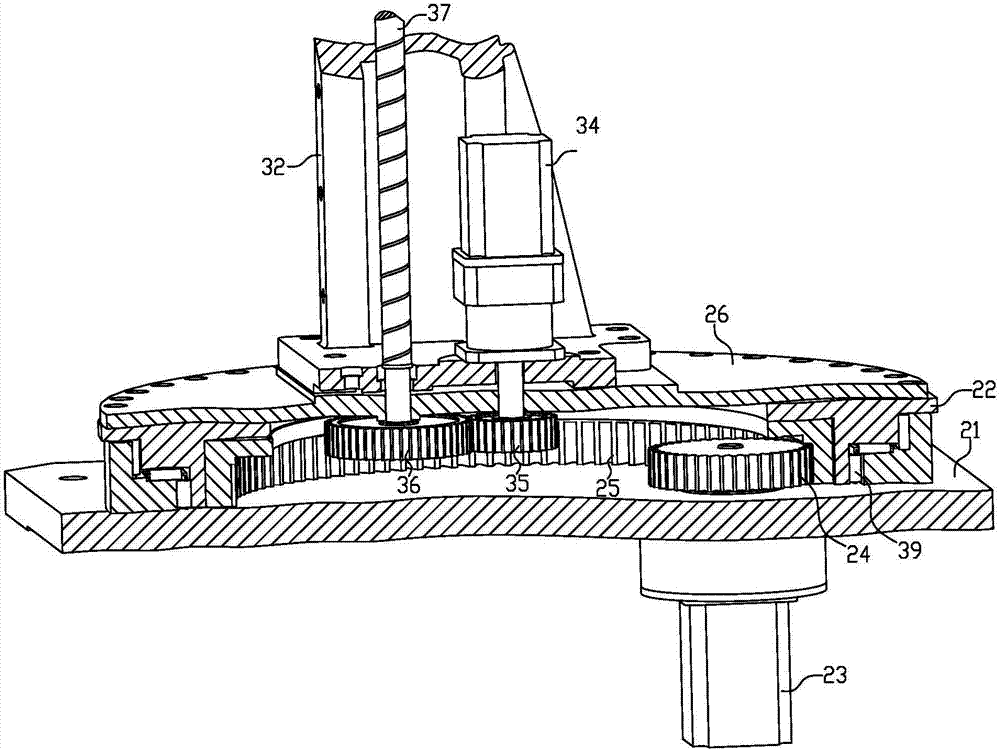

[0029] Such as figure 1 , figure 2 , image 3 and Figure 5 As shown, an omnidirectional wheeled mobile heavy-duty casting robot includes a four-wheel drive wheeled mobile platform 1, a slewing device 2, a lifting device 3, a parallel working arm 4, a counterweight device 5, an end effector 6 and a binocular Vision system7. Wherein, the four-wheel-drive wheeled mobile platform 1 is a carrying and mobile platform of the present invention, including a platform frame 11, a front drive wheel 12, a rear drive wheel 13, a self-balancing hydraulic support leg 14, a controller 15 and a monitor 16. The bottoms of the front and rear ends of the platform frame 11 are provided with navigation sensors, and the navigation sensors adopt magnetic navigation sensors or laser scanners or infrared emitters or ultrasonic emitters; at the front of the platform frame 11 The side, the rear side, the left side and the middle part of the right side are provided with ranging sensors, and the rang...

specific Embodiment approach 2

[0035] Such as figure 1 , Figure 5 , Figure 6 and Figure 7 As shown, the first branch chain 42 includes a first rear universal joint 421, a first telescopic rod group 422 and a first front universal joint 423, and the rear end of the first rear universal joint 421 is connected to the working The arm mounting base 41 is fixedly connected, the rear end of the first telescopic rod group 422 is fixedly connected with the front end of the first rear universal joint 421, and the front end of the first telescopic rod group 422 is connected with the first front universal joint. The rear ends of the joints 423 are fixedly connected, and the front end of the first front universal joint 423 is fixedly connected with the end effector 6 . The second branch chain 43 includes a second rear universal joint 431, a second telescopic rod group 432 and a first front hinge 433, the rear end of the second rear universal joint 431 is fixedly connected to the working arm mounting seat 41, The ...

specific Embodiment approach 3

[0038] Such as figure 1 , Figure 8 and Figure 9 As shown, the end effector 6 specifically adopts a multi-finger asynchronous pneumatic gripper, and the multi-finger asynchronous pneumatic gripper includes an air gripper connecting seat 6-1, a connecting bracket 6-2, and an air gripper mounting plate 6-3, jaw finger 6-4 and finger cylinder 6-5. Wherein, the air claw connecting seat 6-1 is fixedly installed on the front end of the parallel working arm 4; the upper end of the connecting bracket 6-2 is fixedly connected with the air claw connecting seat 6-1, and the lower end of the connecting bracket 6-2 It is fixedly connected with the top of the air claw mounting plate 6-3, and a reinforcing connecting rod 6-21 is also provided in the middle of the connecting bracket 6-2; a guide sleeve 6 is provided at the bottom of the air claw mounting plate 6-3 -31, anti-slip rubber 6-41 is provided on the inside of the lower end of the jaw finger 6-4, and a guide rod 6-42 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com