Processing device and technique for molten iron of titanium slag smelting by-product

A technology for processing equipment and by-products, which is applied in the field of processing equipment for molten iron, a by-product of titanium slag smelting, can solve the problems of low economic efficiency and high production cost of by-product molten iron, and achieve the effects of compact structure, improved utilization rate, and increased added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

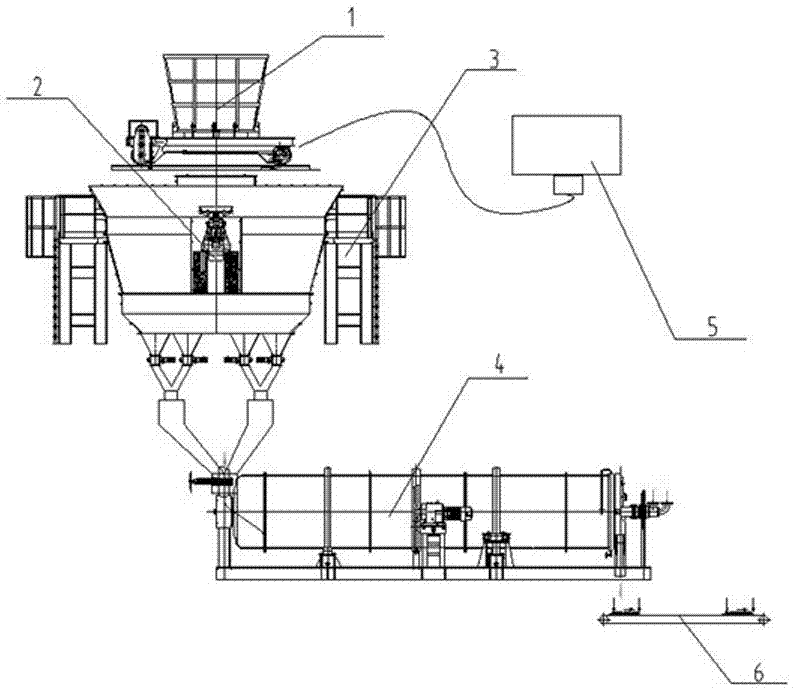

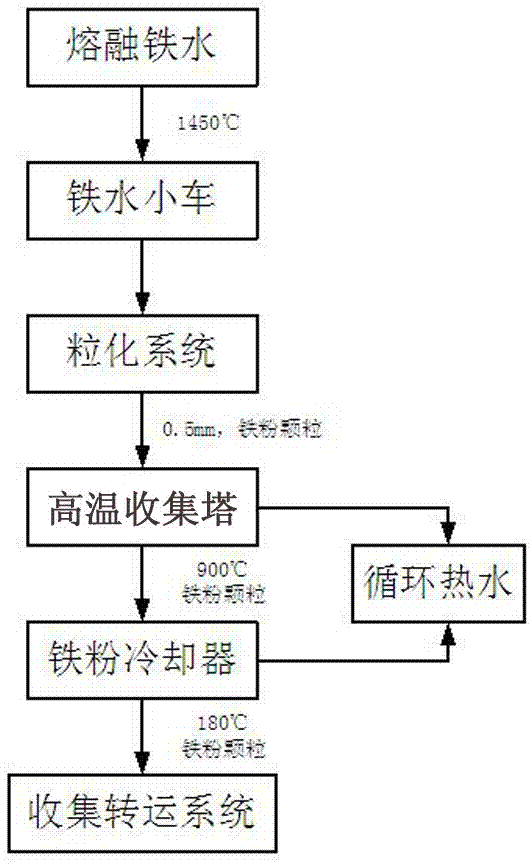

[0049] A treatment equipment and process for molten iron, a by-product of titanium slag smelting, which consists of a molten iron trolley 1, a granulation system 2, a collection tower 3, an iron powder cooler 4, a control system 5, and a collection and transfer system 6 for the treatment of molten iron, a by-product of titanium slag smelting system. The above-mentioned molten iron trolley 1 is arranged on the track, and the molten iron trolley is composed of a driving wheel, a driven wheel, a car body, a stopper mechanism, etc., and the molten iron trolley transports molten iron from the molten iron ditch to the granulation system 2, and passes through The stopper mechanism controls the molten iron flow rate; the granulation system 2 is located below the molten iron trolley 1, and is mainly composed of a frequency conversion motor, bearings, granulation discs, and a rotating shaft. The molten iron enters the granulation disc of the granulation system, Driven by the high-speed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com