Preparation technology for wave-absorbing material with honeycomb sandwich structure

A technology of honeycomb sandwich structure and wave absorbing material, which is applied in protective equipment, clothing, lamination devices, etc., can solve the problem of difficulty in controlling the distribution uniformity of wave absorbing particles, and achieve the effect of wide wave absorbing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Fiber material: choose fine denier carbon black fiber (22.2dtex / 4F×12) containing nano-carbon black particles and fine denier polyester fiber (81dtex / 30F×3) to cooperate.

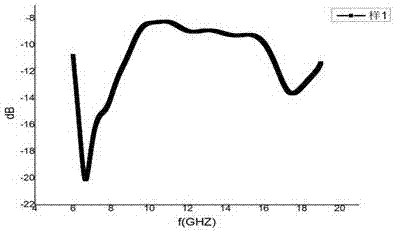

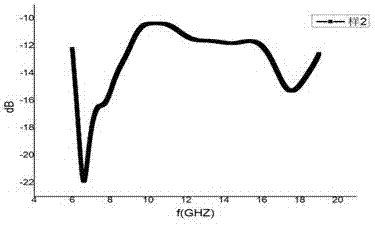

[0034] (2) Design of honeycomb layered structure: the designed honeycomb shape is square rhombus, arranged in relative arrangement, the diagonal size of sample 1 rhombus (2.8cm×4.9cm), see figure 1 , sample 2 rhombus diagonal size (1.5cm×2.5cm), see figure 2 . The square diamonds of the two fibers of each type are equal in size, each diamond is a double-layer single-sided plain weave, and the upper and lower fabrics are interwoven at the junction of the diamonds; the front and back of the fabric are mirror images of each other.

[0035] (3) Weaving of fabric with honeycomb layered structure: According to the design requirements of yarn thickness and honeycomb layered structure, design the pattern and color structure of the fabric in the computerized flat knitting machine pattern design system, ...

Embodiment 2

[0044] (1) Fiber material: choose to add nano-TiO 2 Matte polyester fiber (81dtex / 30F×3) with particles and fine-denier carbon black fiber (22.2dtex / 4F×12) containing nano-carbon black particles are combined.

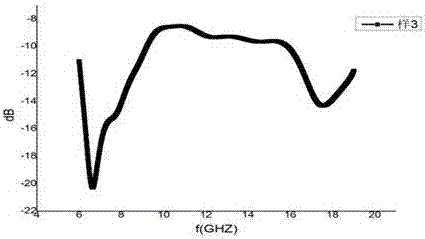

[0045] (2) Design of honeycomb layered structure: the designed honeycomb structure is a quadrangular rhombus, and the diagonal size of the rhombus (2.7cm×5.2cm) is arranged in a staggered manner, see Figure 5 shown. The fabric is a double-layer single-sided plain weave, and the upper and lower fabrics are interwoven at the intersection of the two yarns; the front and back of the fabric are mirror images of each other.

[0046] (3) Weaving of fabric with honeycomb layered structure: According to the design requirements of yarn thickness and honeycomb layered structure, design the pattern and color structure of the fabric in the computerized flat knitting machine pattern design system, and weave on the machine. The needle size of the computerized flat knitting machine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com