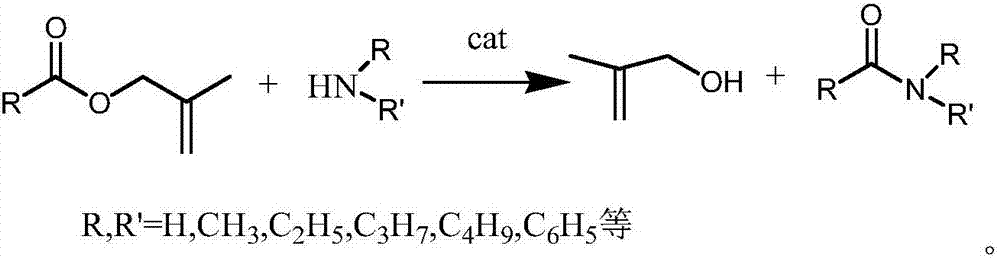

Method for preparing methallyl alcohol and amide simultaneously

A technology of methallyl alcohol and methallyl carboxylate, which is applied in the field of preparation of methallyl alcohol and a series of amide compounds, can solve the problems of instability and easy polymerization of methallyl aldehyde, and achieve the reaction Effects of mild conditions and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The preparation method of embodiment 1 raw material methallyl acetate

[0023] In a 5L reaction flask, stir, and add 2000g of a 30% sodium acetate aqueous solution. Heat to about 70°C, add 100g of cuprous chloride as a catalyst, slowly add 600g of methallyl chloride dropwise, control the temperature within 70°C, after the dropwise addition of methallyl chloride is completed, slowly raise the temperature and keep reflux, Until the reflux temperature is 94°C, the reaction is over; standing for stratification, the upper layer is methallyl acetate, rectification to obtain 520g, 99% methallyl acetate, the obtained methallyl acetate HNMR 1.7ppm3H, 2.0ppm3H, 4.75ppm2H, 4.9ppm1H, 5.0ppm1H.

Embodiment 2

[0024] The preparation of embodiment 2 methallyl alcohol and formamide

[0025] Stir in a 5L reaction flask, add 2000g of methallyl formate, add 100g of basic alumina, and cool to 0°C. Ammonia gas is introduced slowly, and the temperature of the reaction system is controlled at about 0-5°C. About 350g of ammonia gas was introduced, and the gas phase detection of methallyl formate was basically consumed. Stop responding. Atmospheric distillation collected fractions at 114°C, which were 1368 g of methallyl alcohol, with a yield of 95%. The obtained methallyl alcohol HNMR 1.7ppm3H, 4.2ppm2H, 4.9ppm1H, 5.0ppm1H, 2.0ppm1H. Change vacuum distillation, collect formamide distillate 850g, yield 94.4%. Formamide HNMR 2.0 ppm 2H, 8.1 ppm 1H.

Embodiment 3

[0026] The preparation of embodiment 3 methallyl alcohol and N-methylformamide

[0027] In a 5L reaction flask, stir, add 2000g of methallyl formate, add 90g of basic alumina, and cool to 5°C. Slowly feed methylamine gas, and control the temperature of the reaction system in the range of 3-10°C. About 650g of methylamine gas was introduced, and the gas phase detection of methallyl formate was basically consumed. Stop responding. Atmospheric pressure distillation collects 114°C fraction, which is 1400g of methallyl alcohol. Distill under reduced pressure to collect 1080 g of N-methylformamide fractions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com