Sugarcane peel fiber based blended PBS (polybutylene succinate) degradable plastic and preparation method thereof

A technology for degrading plastics and sugarcane husks, applied in the field of PBS plastics, to achieve the effects of avoiding environmental pollution, accelerating degradation, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

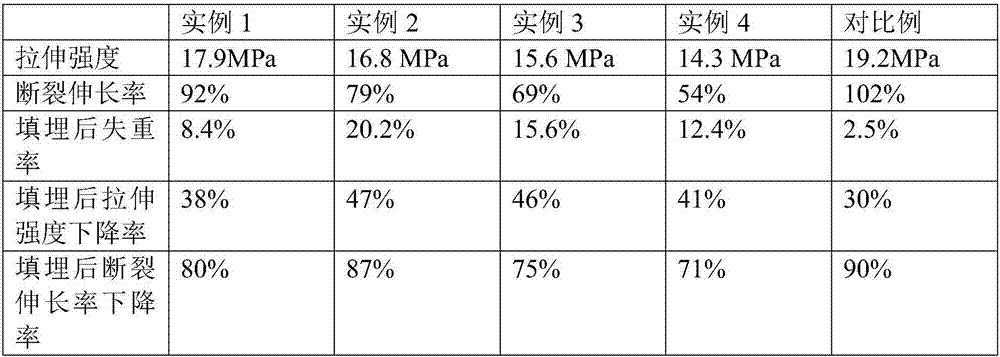

Examples

Embodiment 1

[0039] A sugarcane husk fiber-based blended PBS degradable plastic, the formula is as follows:

[0040] PBS resin 1000g, silane coupling agent modified sugarcane husk fiber 50g, PP-g-MAH 10g, corn oil 5g, antioxidant 168 5g.

[0041] The preparation method of the above-mentioned sugarcane husk fiber-based blended PBS degradable plastic is as follows: 1000g of PBS resin, 50g of silane coupling agent modified sugarcane husk fiber, 10g of PP-g-MAH, 5g of corn oil, and 5g of antioxidant 168 Put into a high-speed mixer and mix evenly, then pour the mixed raw materials into a twin-screw extruder to melt, set the temperature of the extruder to 165°C, 175°C, 180°C, 190°C, 195°C, mix evenly, extrude and cut Granules, that is, sugarcane husk fiber-based blended PBS degradable plastics.

[0042] Wherein, the preparation method of described silane coupling agent modified sugarcane husk fiber is:

[0043] (1) Collect the sugarcane skins discarded by the fruit stand, remove the horizontal...

Embodiment 2

[0048] A sugarcane husk fiber-based blended PBS degradable plastic, the formula is as follows:

[0049] PBS resin 1000g, silane coupling agent modified sugarcane husk fiber 100g, PP-g-MAH 20g, sesame oil 5g, antioxidant 1010 10g.

[0050] The preparation method of the above-mentioned sugarcane husk fiber-based blended PBS degradable plastic is as follows: 1000g of PBS resin, 100g of silane coupling agent modified sugarcane husk fiber, 20g of PP-g-MAH, 5g of sesame oil, and 10g of antioxidant 1010 are put into The high-speed mixer is mixed evenly, and then the mixed raw materials are poured into the twin-screw extruder to melt. The temperature of the extruder is set at 165°C, 175°C, 180°C, 190°C, and 195°C. After mixing evenly, extrude and pelletize , that is, sugarcane husk fiber-based blended PBS degradable plastics.

[0051] Wherein, the preparation method of described silane coupling agent modified sugarcane husk fiber is:

[0052] (1) Collect discarded green sugarcane sk...

Embodiment 3

[0057] A sugarcane husk fiber-based blended PBS degradable plastic, the formula is as follows:

[0058] PBS resin 1000g, silane coupling agent modified sugarcane husk fiber 150g, PP-g-MAH 20g, rapeseed oil 10g, antioxidant PS800FL 5g.

[0059] The preparation method of the above-mentioned sugarcane husk fiber-based blended PBS degradable plastic is as follows: 1000g of PBS resin, 150g of silane coupling agent modified sugarcane husk fiber, 20g of PP-g-MAH, 10g of rapeseed oil, and antioxidant PS800FL Put 5g into a high-speed mixer and mix evenly, then pour the mixed raw materials into a twin-screw extruder to melt, set the temperature of the extruder to 165°C, 175°C, 180°C, 190°C, 195°C, mix evenly and extrude Cut into pellets to obtain the sugarcane husk fiber-based blended PBS degradable plastic.

[0060] Wherein, the preparation method of described silane coupling agent modified sugarcane husk fiber is:

[0061] (1) Collect red sugarcane skins, remove cross-sections, wash...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com