A method for purifying medium-chain and medium-long-chain mixed diglycerides

A technology of diglyceride and purification method, which is applied in the field of oil and fat, and can solve the problems such as the complexity of the crude product system of medium and long chain diglyceride

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

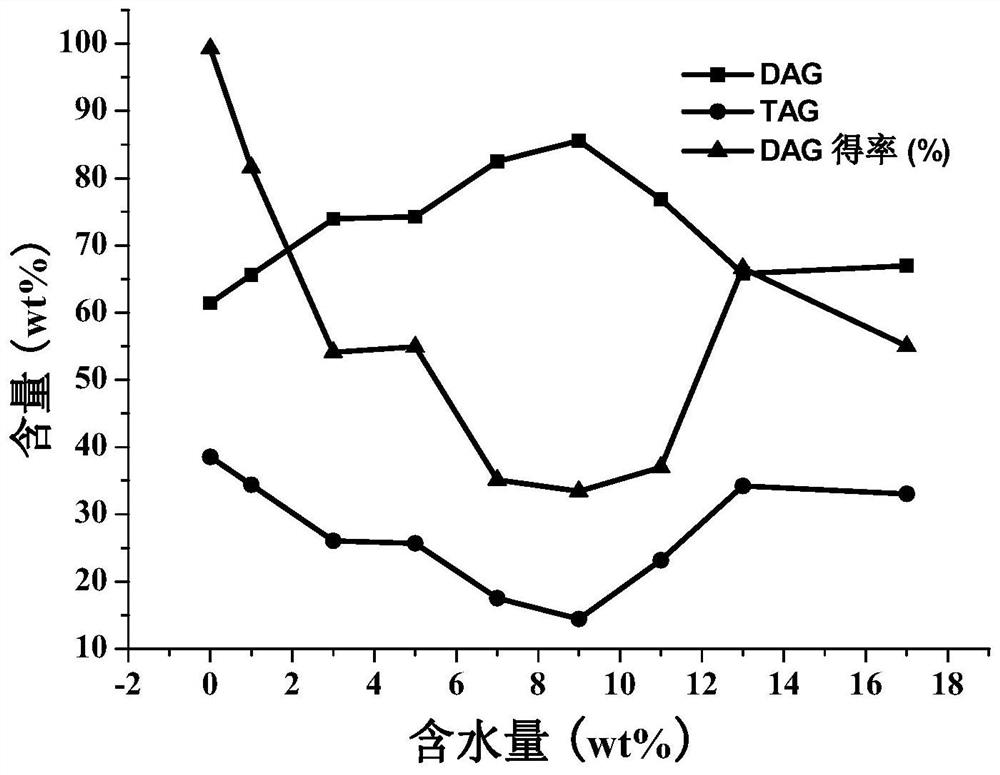

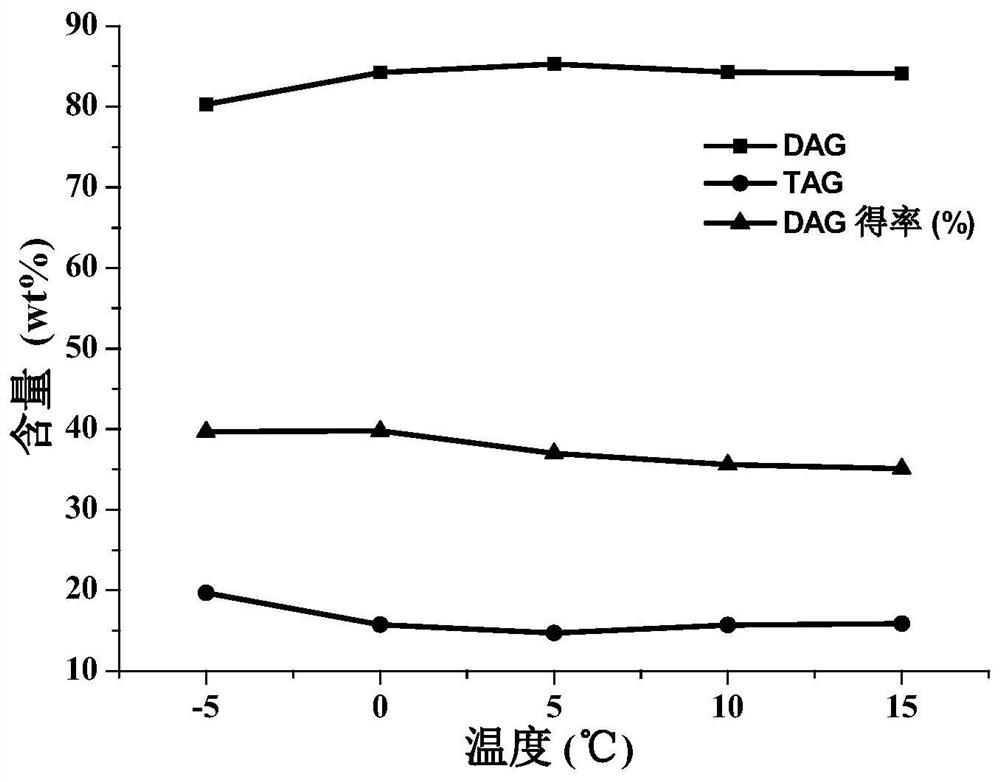

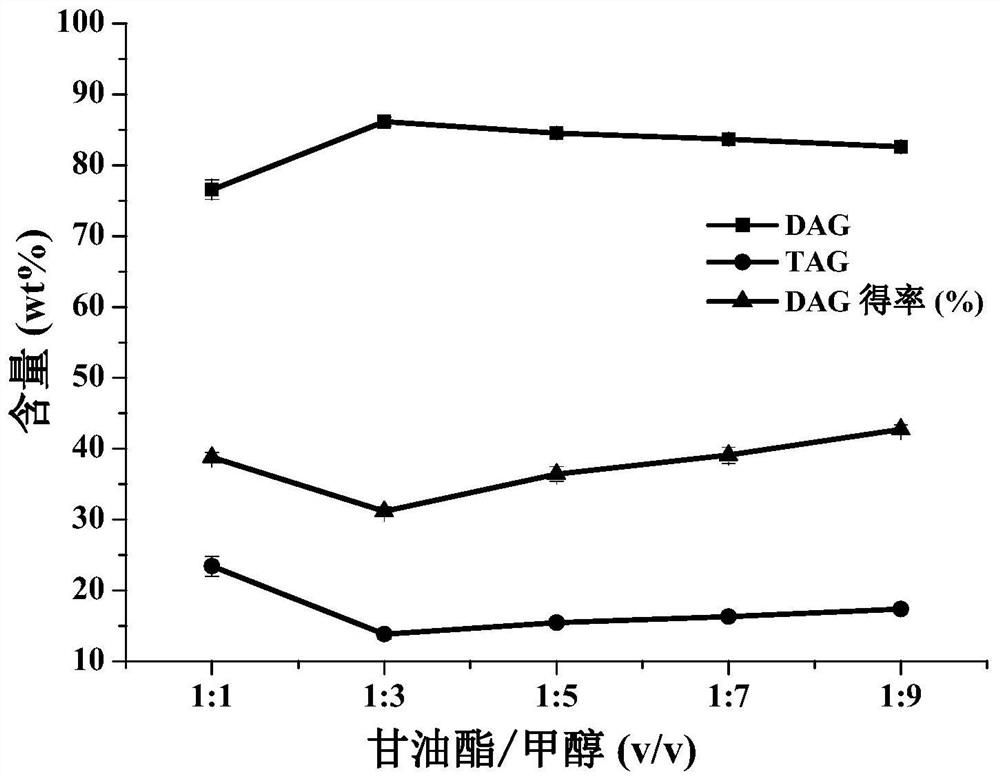

Method used

Image

Examples

Embodiment 1

[0037](1) Novozyme 435 enzyme (Novozyme 435) that is equivalent to 5% of the total mass of the reactant is placed in a round-bottomed flask with magnetic stirring in an oil bath, then the oil bath heating switch is turned on to heat the oil bath, and the oil bath is heated. Heat the pot to 65°C; long-chain fatty acids mixed with monoglyceride and caprylic acid (monoglyceride / caprylic acid, 1:3 (mol / mol)) as reactants; after the temperature of the oil bath is preheated to 65°C, turn on the magnetic force Stir to 20rpm, stir the reactants evenly in the oil bath, initiate the enzyme-catalyzed reaction, and collect the crude product of lactonization in the round bottom flask; after the reaction is carried out for 40 minutes, turn off the magnetic stirring and the oil bath;

[0038] (2) molecular distillation is carried out on the obtained esterification crude product, and at distillation temperature is 160 ℃, and the rotating speed of scraping film electrode is 200rpm, and vacuum d...

Embodiment 2

[0044] This example is the same as Example 1 except the following technical features: caprylic acid monoglyceride described in step (4): anhydrous methanol carries out low-temperature high-speed centrifugal purification according to 1:3 (v / v) and 9% water, The temperature is 0°C, the rotation speed is 10000r / min, and the time is 5min.

[0045] Through the detection and calculation of the method described in Example 1, the content of medium-chain and medium-long-chain diglyceride mixture in the heavy phase of the crude product obtained after step (2) molecular distillation in this example is 56.3%; The content of the product reaches 61.3% after uniform stirring and crystallization; the final product is obtained after step (4) low-temperature high-speed centrifugation, and the content of the medium-chain and medium-long-chain diglyceride mixture is 86.6%.

Embodiment 3

[0047] This implementation example is the same as Example 1 except the following technical features: the raw material caprylic acid monoglyceride described in step (4): anhydrous methanol carries out low-temperature high-speed centrifugal purification according to 1:5 (v / v) and 9% water , temperature 0°C, rotation speed 10000r / min, time 5min.

[0048] Through the detection and calculation of the method described in Example 1, the content of the mixture of medium-chain and medium-long-chain diglycerides in the heavy phase of the crude product obtained after step (2) molecular distillation in this example is 56.3%; The content of the product reaches 61.3% after uniform stirring and crystallization; the final product is obtained after step (4) low-temperature high-speed centrifugation, and the content of the medium-chain and medium-long-chain diglyceride mixture is 84.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com