Preparation method of menthol microcapsules

A technology of microcapsules and menthol is applied in the field of preparation of menthol microcapsules, and achieves the effects of reduced preparation and use costs, good film-forming properties and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

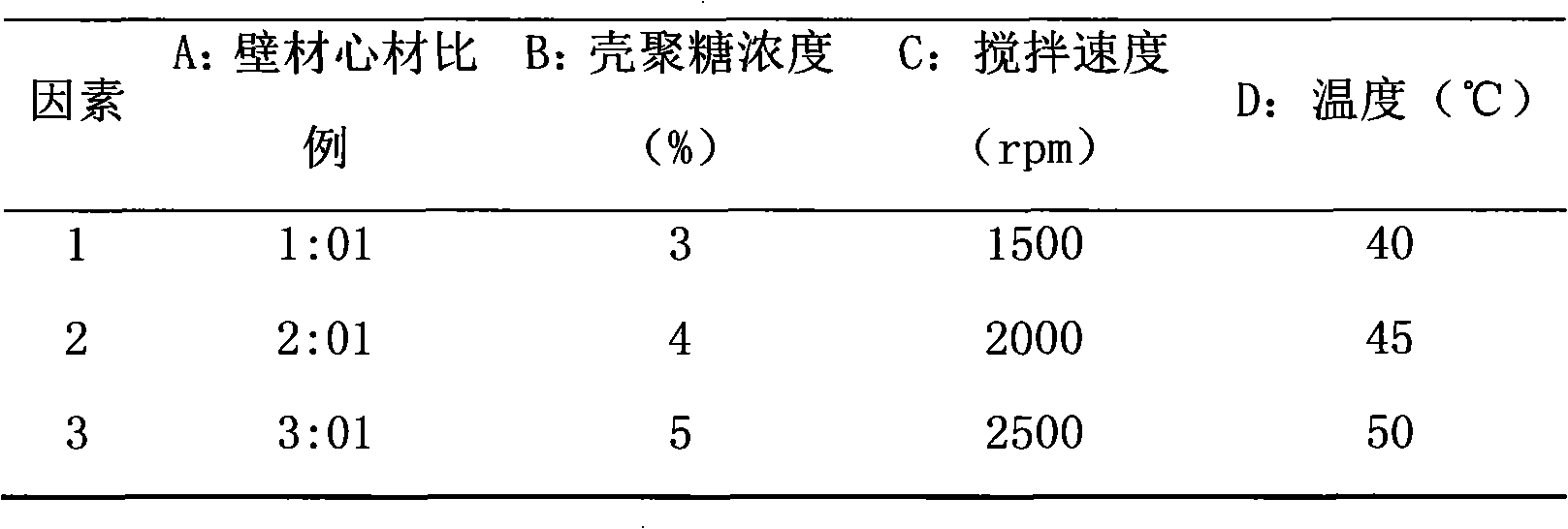

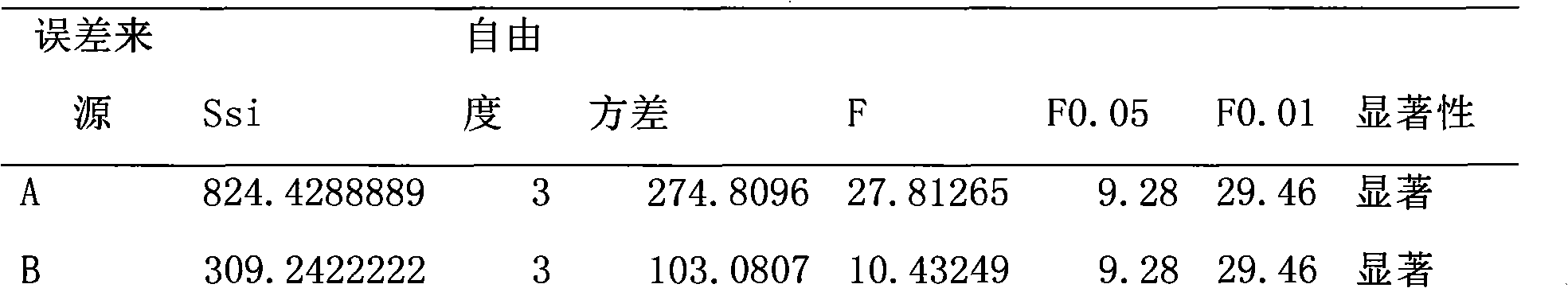

Method used

Image

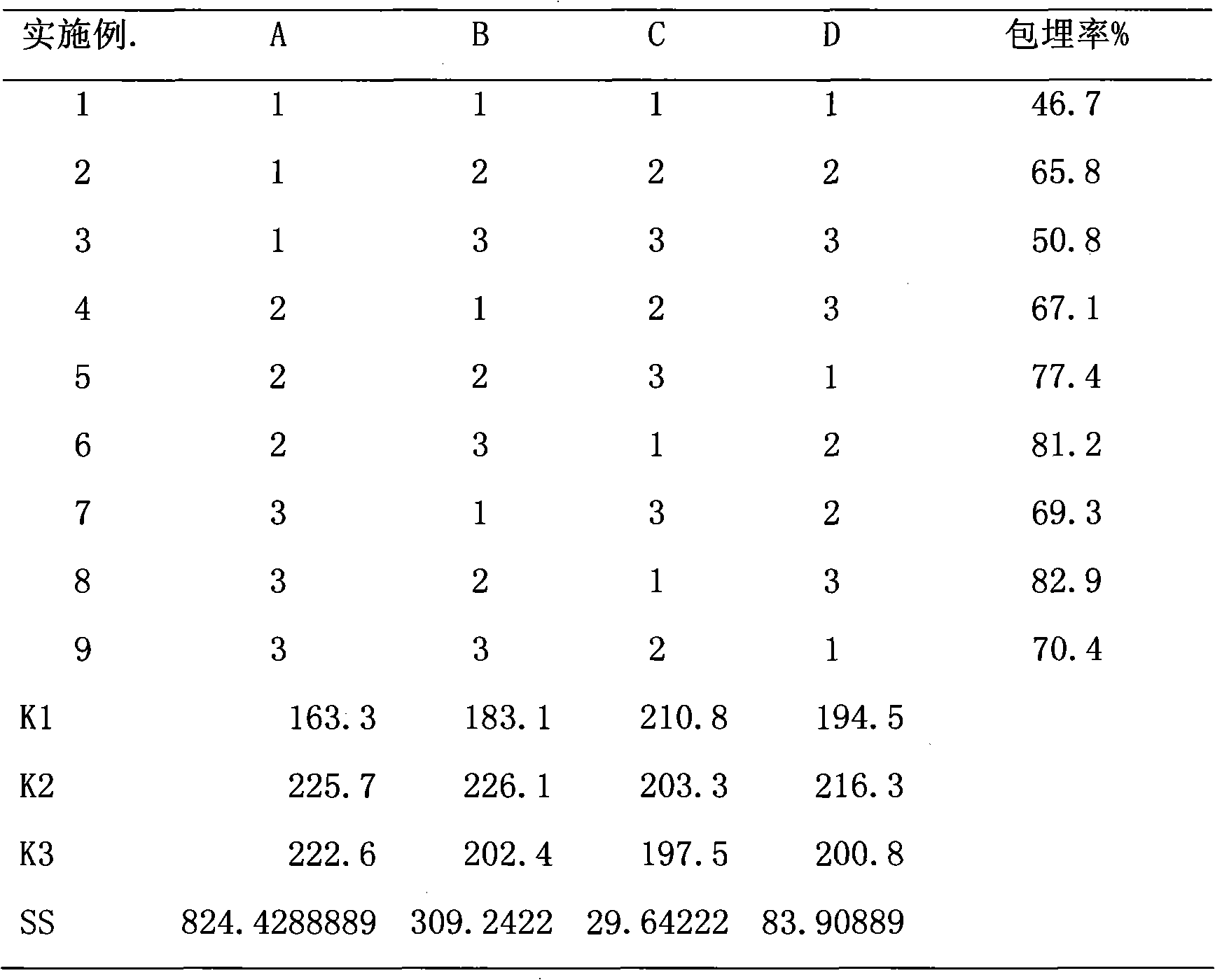

Examples

Embodiment 1

[0034] A method for preparing menthol microcapsules uses menthol as a core material, chitosan as a wall material, and uses soluble chitosan with a degree of deacetylation of 80%. Monoglycerides and Tween 40 are used as composite emulsifiers. The monoglycerides used are glycerin fatty acid esters in powder form with an HLB of 5. The Tween 40 used is a yellowish waxy solid with an HLB of 15.5. After high-pressure emulsification, modified starch is added for cross-linking, and finally spray drying technology is used to prepare powdered menthol microcapsule products. The specific preparation steps are as follows:

[0035] (1) Preparation of modified starch: corn starch is used as raw material, the corn starch used is white powder, modified starch is obtained after treatment, and the modified starch is characterized by: ionic type is anion, appearance is white powder, gelatinization temperature is 65℃ , Gelatinized liquid is stable and does not stratify. Sodium periodate is the oxida...

Embodiment 2

[0046] The steps are similar to those in Example 1, except that the final mass percentage of the microcapsule emulsion is controlled as follows: chitosan 4%, menthol 4%, crosslinking temperature 45°C, and stirring speed during crosslinking 2000rpm.

[0047] After testing, the obtained menthol microcapsule embedding rate was 65.8%.

Embodiment 3

[0048] Example 3: The steps are similar to Example 1, except that the final mass percentage of the microcapsule emulsion is controlled as follows: chitosan 5%, menthol 5%, cross-linking temperature is 50°C, and the stirring speed during cross-linking is 2500 rpm .

[0049] After testing, the embedding rate of the obtained menthol microcapsules was 50.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com