Method for ultra-quickly preparing high-performance ZrNiSn bulk thermoelectric material through one step

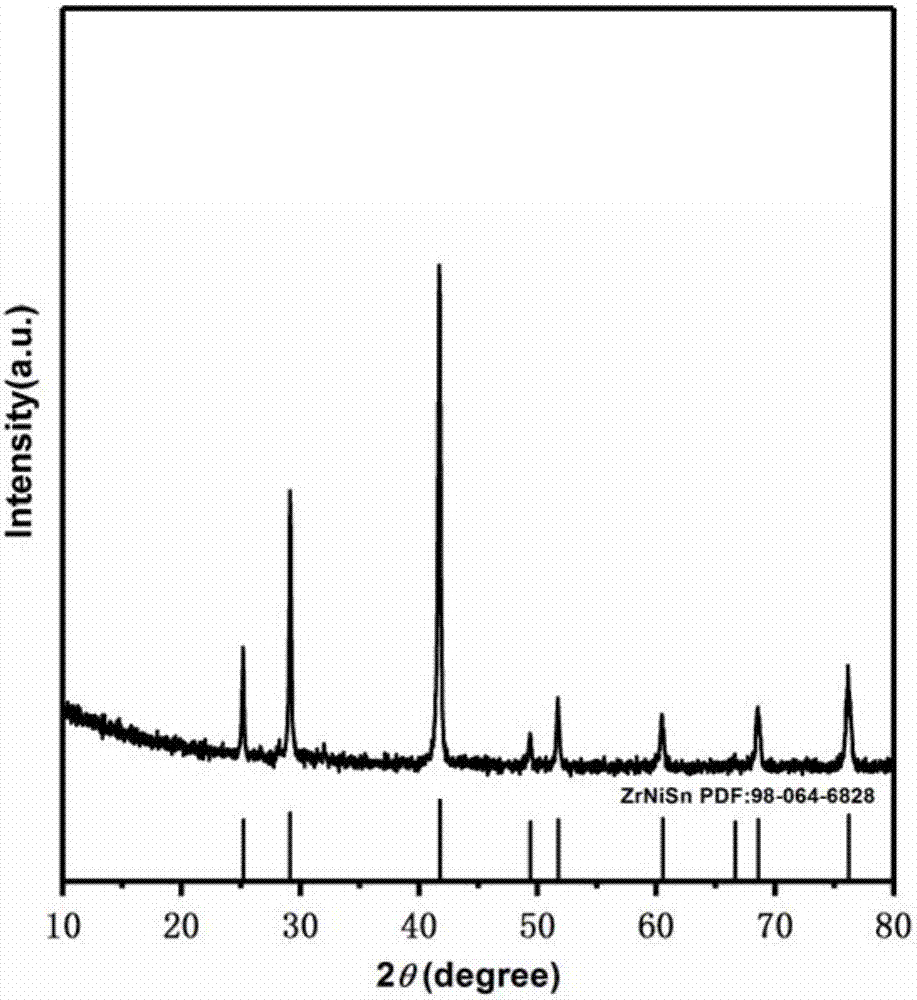

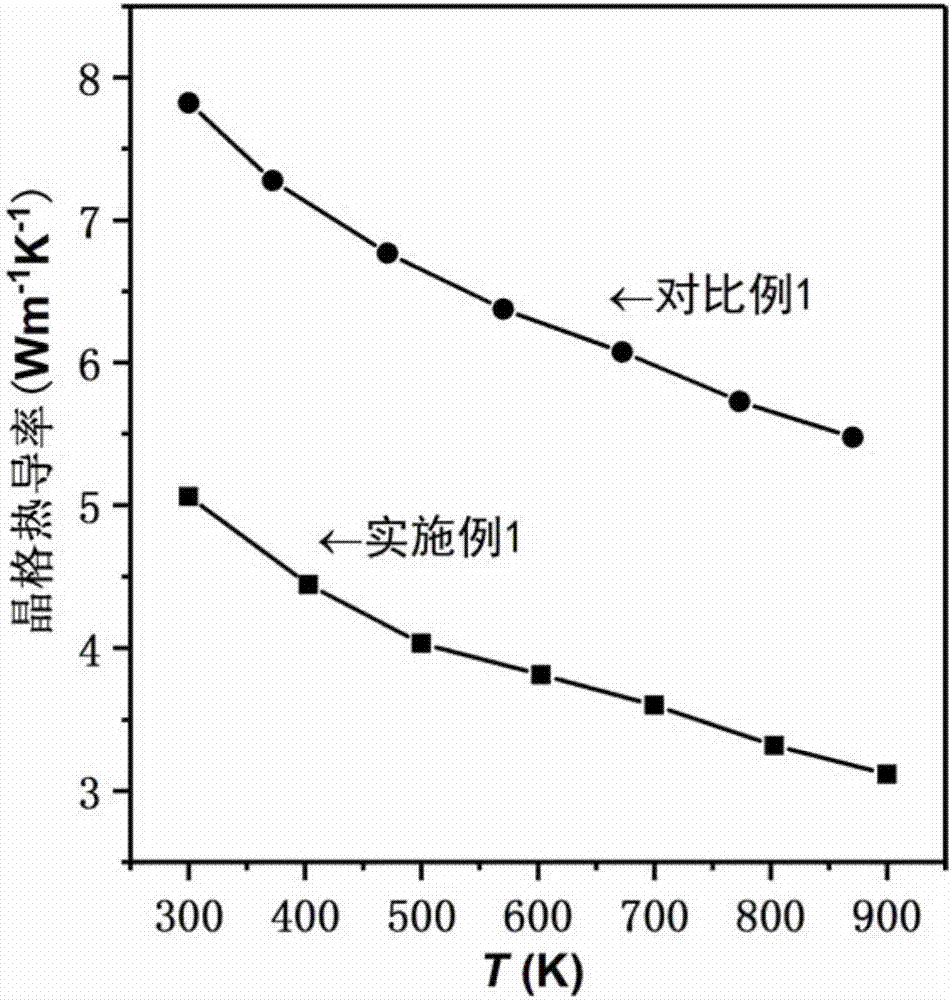

A thermoelectric material and high-performance technology, which is applied in the field of ultra-fast preparation of high-performance ZrNiSn bulk thermoelectric materials, can solve problems such as oxidation, and achieve the effects of simple operation, reduced lattice thermal conductivity, and improved thermoelectric performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] One-step ultrafast method for preparing high-performance ZrNiSn bulk thermoelectric material, it comprises the following steps:

[0038] 1) Weigh 12g of Zr powder, Ni powder, and Sn powder according to the stoichiometric ratio of 1:1:1 as raw materials, and mix them uniformly to obtain the reactant; cold press the reactant at 4MPa for 2min to obtain a preform with a diameter of 16mm and a height of 12mm cylindrical body;

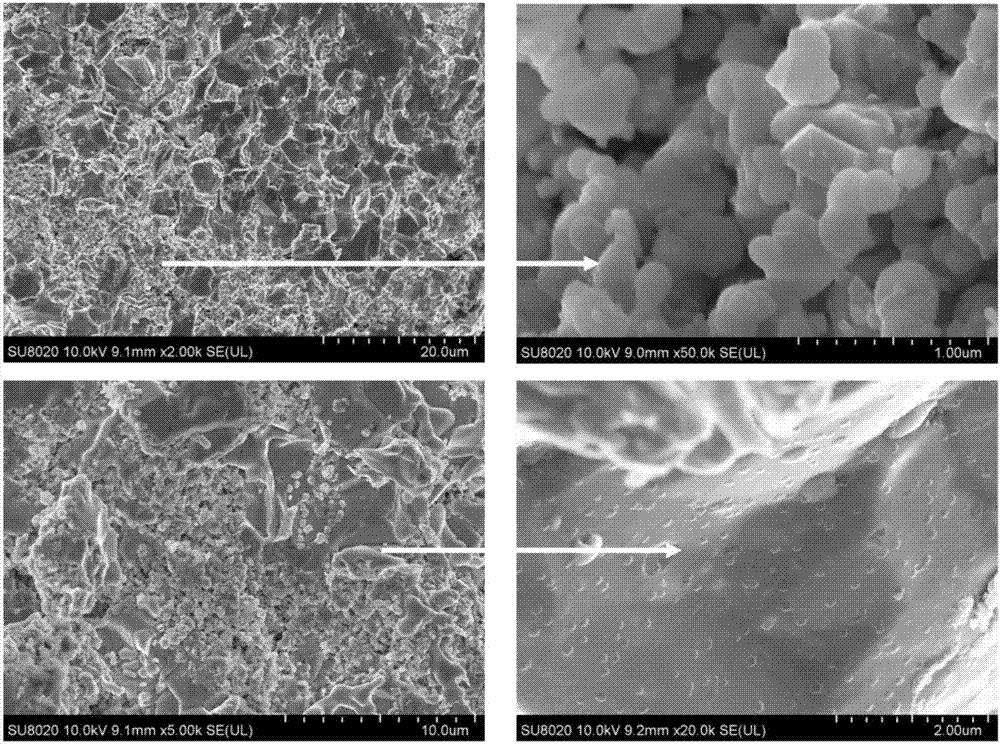

[0039] 2) Wrap the pressed columnar green body with quartz sand and put it into a steel mold, put the steel mold into the reaction chamber, and fill it with 50kPa argon after vacuuming; then, under the protection of argon atmosphere, Tungsten argon arc welding is used to initiate the chemical reaction, the arc starting current is 20A, and then an axial high pressure of 200MPa is applied to the columnar body within 2s, and the pressure is maintained for 10s, and finally a high-performance ZrNiSn bulk thermoelectric material with a density of 98.3% is o...

Embodiment 2

[0044] One-step ultrafast method for preparing high-performance ZrNiSn bulk thermoelectric material, it comprises the following steps:

[0045] 1) Weigh 12g of Zr powder, Ni powder, and Sn powder according to the stoichiometric ratio of 1:1:1 as raw materials, and mix them uniformly to obtain the reactant; cold press the reactant at 4MPa for 2min to obtain a preform with a diameter of 16mm and a height of 12mm cylindrical body;

[0046] 2) Wrap the pressed columnar green body with quartz sand and put it into a steel mold, put the steel mold into the reaction chamber, and fill it with 50kPa argon after vacuuming; then, under the protection of argon atmosphere, Tungsten argon arc welding is used to initiate the chemical reaction, the arc starting current is 20A, and then an axial high pressure of 300MPa is applied to the columnar blank within 2s, and the pressure is maintained for 10s, and finally a high-performance ZrNiSn bulk thermoelectric material with a density of 98.5% is ...

Embodiment 3

[0048] One-step ultrafast method for preparing high-performance ZrNiSn bulk thermoelectric material, it comprises the following steps:

[0049] 1) Weigh 12g of Zr powder, Ni powder, and Sn powder according to the stoichiometric ratio of 1:1:1 as raw materials, and mix them uniformly to obtain the reactant; cold press the reactant at 4MPa for 2min to obtain a preform with a diameter of 16mm and a height of 12mm cylindrical body;

[0050] 2) Wrap the pressed columnar green body with quartz sand and put it into a steel mold, put the steel mold into the reaction chamber, and fill it with 30kPa argon after vacuuming; then, under the protection of argon atmosphere, Tungsten argon arc welding is used to initiate a chemical reaction, the arc starting current is 20A, and then an axial high pressure of 300MPa is applied to the columnar blank within 2s, and the pressure is maintained for 10s, and finally a high-performance ZrNiSn bulk thermoelectric material with a density of 97.97% is o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thermoelectric figure of merit | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com