Dewatering device for paper making

A technology of dehydration device and suction roller, which is applied in papermaking, papermaking machines, textiles and papermaking, etc. It can solve the problems of poor dehydration ability affecting paper processing and product quality, affecting the effect of wet paper pressing, and low paper compactness. Achieve enhanced dehydration effect, improve dehydration efficiency, and reduce drying energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific embodiments of the present invention will be further described below with reference to the accompanying drawings. It should be noted here that the descriptions of these embodiments are used to help the understanding of the present invention, but do not constitute a limitation of the present invention. In addition, the technical features involved in the various embodiments of the present invention described below can be combined with each other as long as they do not conflict with each other.

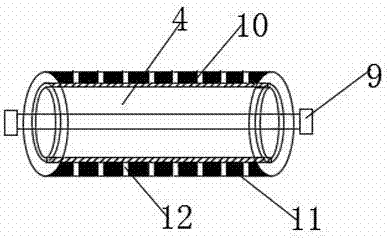

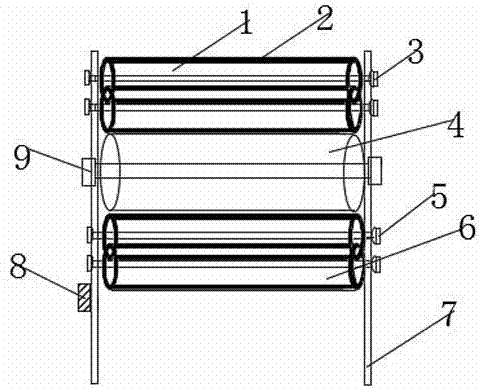

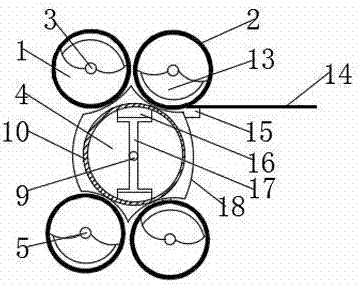

[0017] see figure 1 , figure 2 and image 3 , The present invention provides a technical solution: a dewatering device for papermaking, comprising a bracket 7, a driven water suction roller group 1 is arranged on the upper surface of the bracket 7, and a belt drive shaft 15 is arranged on the right side of the driven water suction roller group 1, A belt 14 for conveying paper is arranged on the belt transmission shaft 15, and a driven suction roller shaft 3 is arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com