Thermal power generator set and refuse incinerator working medium combined power generation system

A technology for waste incinerators and thermal power units, applied in incinerators, combined combustion mitigation, machines/engines, etc., can solve problems such as low efficiency and steam turbine cycle efficiency of less than 23%, so as to improve heat utilization efficiency and unit The effect of large capacity and improved cycle efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

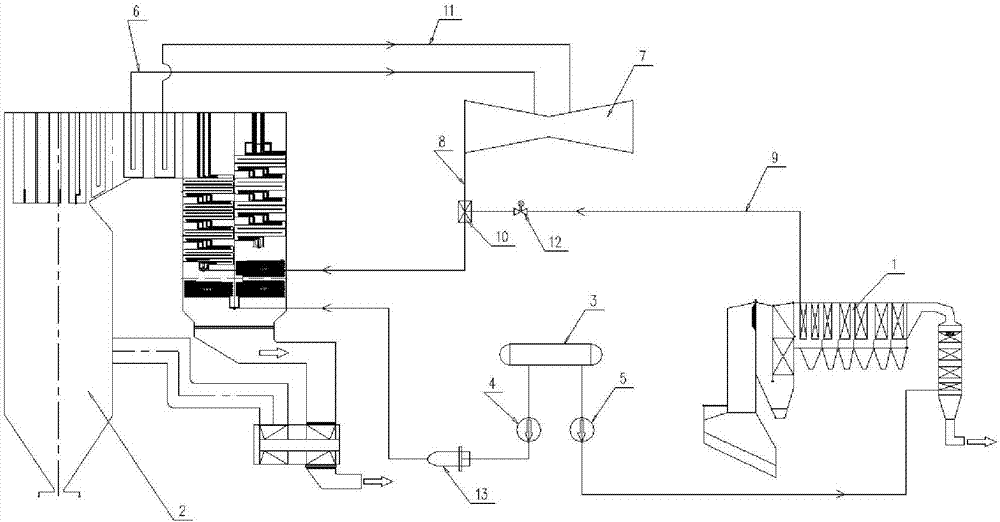

[0017] Specific implementation mode one: combine figure 1 Describe this embodiment, the combined power generation system of a thermal power unit and a waste incinerator working medium in this embodiment includes a waste incinerator body 1, a pulverized coal boiler body 2, a deaerator 3 and a turbogenerator set 7,

[0018] The pulverized coal boiler body 2 communicates with the deaerator 3 through the pulverized coal boiler feed water pump 4, and the pulverized coal boiler main steam pipe 6 of the pulverized coal boiler body 2 and the reheater outlet pipe 11 of the pulverized coal boiler communicate with the steam The turbo-generator set 7 establishes a connection relationship, and the high-pressure exhaust steam of the turbo-generator set 7 is introduced into the reheater heating surface of the pulverized-coal boiler body 2 by the reheater inlet pipe 8 of the pulverized-coal boiler to absorb heat;

[0019] The waste incinerator body 1 communicates with the deaerator 3 through ...

specific Embodiment approach 2

[0023] Specific implementation mode two: combination figure 1 To illustrate this embodiment, a cut-off valve 12 is arranged on the main steam pipe 9 of the waste incinerator described in the combined power generation system of the thermal power unit and the waste incinerator in this embodiment. In this way, the main steam pipe 9 of the waste incinerator is provided with a cut-off valve, and when the waste incinerator is shut down, the body 1 of the waste incinerator and the body 2 of the pulverized coal boiler can be disconnected.

specific Embodiment approach 3

[0024] Specific implementation mode three: combination figure 1 To illustrate this embodiment, the pulverized coal boiler feed water described in the thermal power unit and waste incinerator combined power generation system of this embodiment is drawn through the pulverized coal boiler feed water pump 4 and then introduced into the pulverized coal boiler body 2 after being heated by the high pressure heating system 13 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com