Energy-saving internal combustion engine crankshaft mechanism capable of increasing torque

An internal combustion engine and crankshaft technology, applied in the field of internal combustion engines, can solve the problems of low torque, waste of energy, affecting the torque power output of the internal combustion engine, etc., and achieve the effect of improving energy conversion rate and high torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

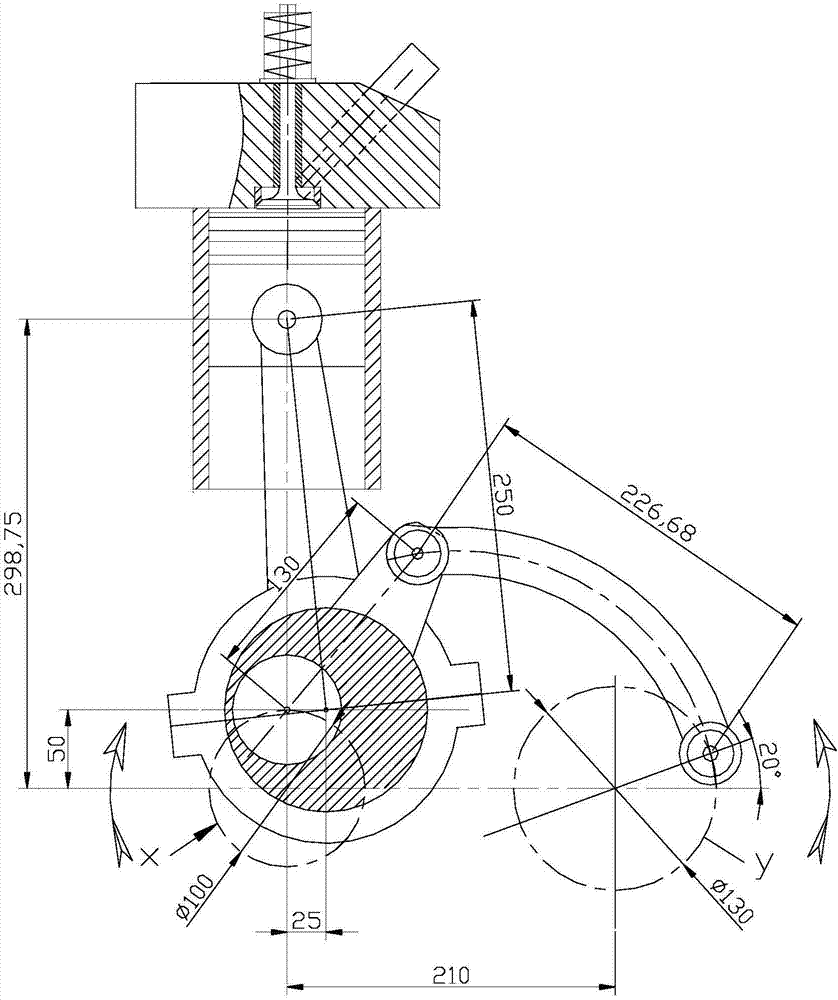

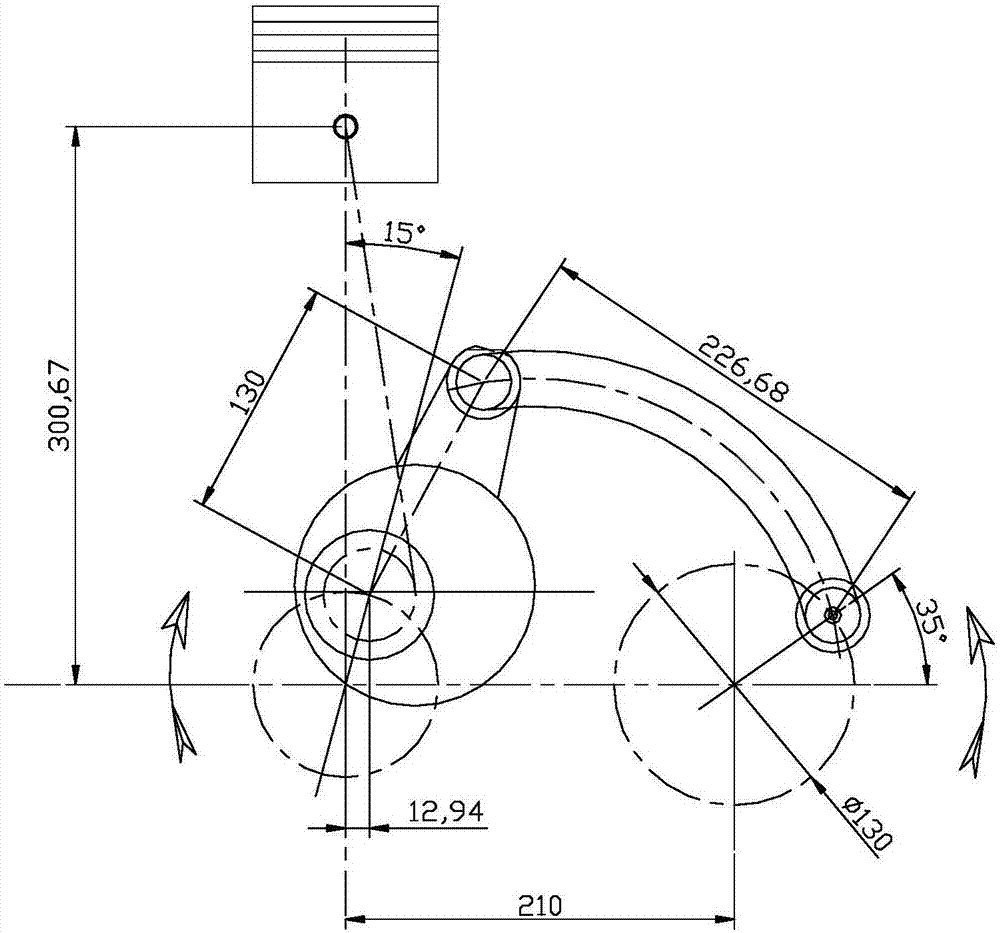

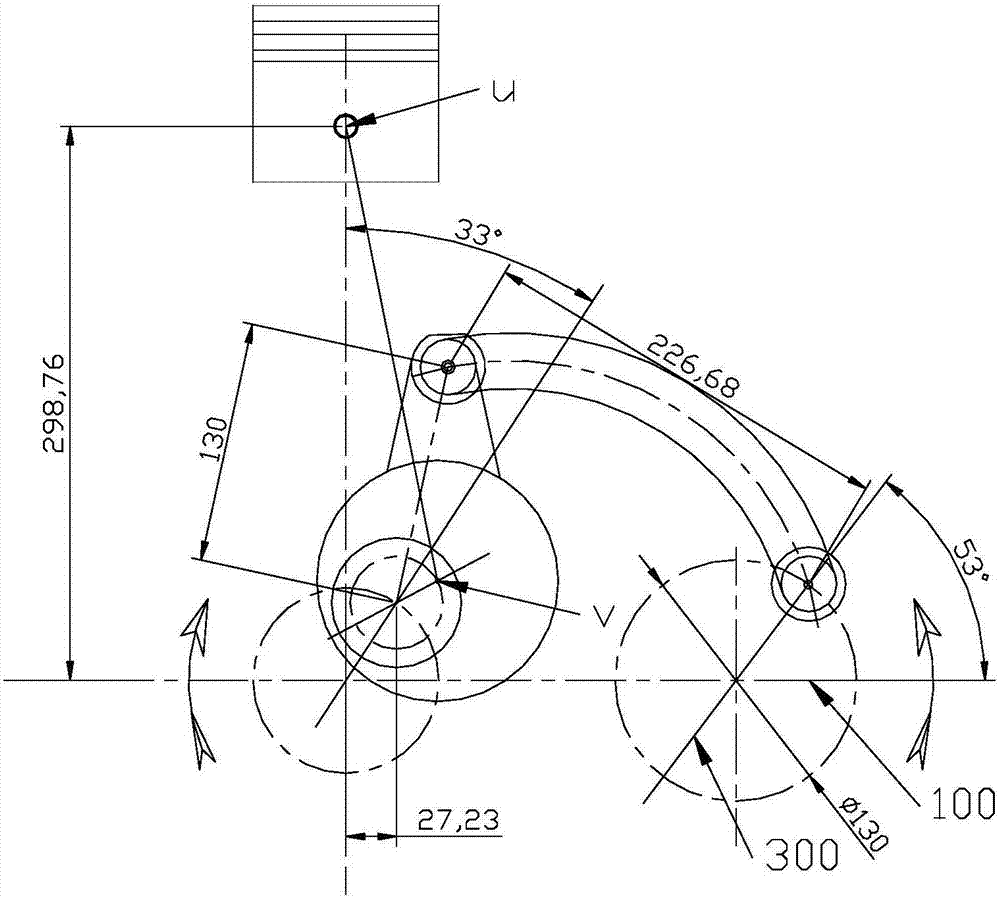

[0031] Take the eccentricity of crankshaft 1 as 50mm, the eccentricity of eccentric casing 4 as 25mm, the eccentricity of pull rod small crankshaft 3 as 65mm, the hole distance of tie rod 5 as 226.68mm, and the center distance between crankshaft 1 and pull rod small crankshaft 3 as 210mm as an example. Be explained.

[0032] see figure 1 The shown energy-saving and torque-enhancing internal combustion engine crankshaft mechanism includes a crankshaft 1, an eccentric sleeve 4, a pull rod 5, a pull rod small crankshaft 3, a connecting rod 2, and a piston 7.

[0033] Two meshing gears 6 with the same number of teeth are connected to the same end of the crankshaft 1 and the pull rod small crankshaft 3 by keys respectively. In order to prevent the size outer diameter of the gear 6 from being too large, an even number of meshing gears 6 can be set between the crankshaft 1 and the pull rod small crankshaft 3 for transmission, so that the crankshaft 1 and the pull rod small crankshaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com