Spraying demonstration device of adopting machine vision and fiber optic gyroscope to position cooperatively

A fiber optic gyroscope and machine vision technology, applied in the direction of using optical devices, measuring devices, instruments, etc., can solve the problems of high job dependence of programming engineers, complex structure of teaching equipment, insufficient working range, etc., to simplify teaching equipment. structure, improve equipment flexibility, and improve the effect of flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

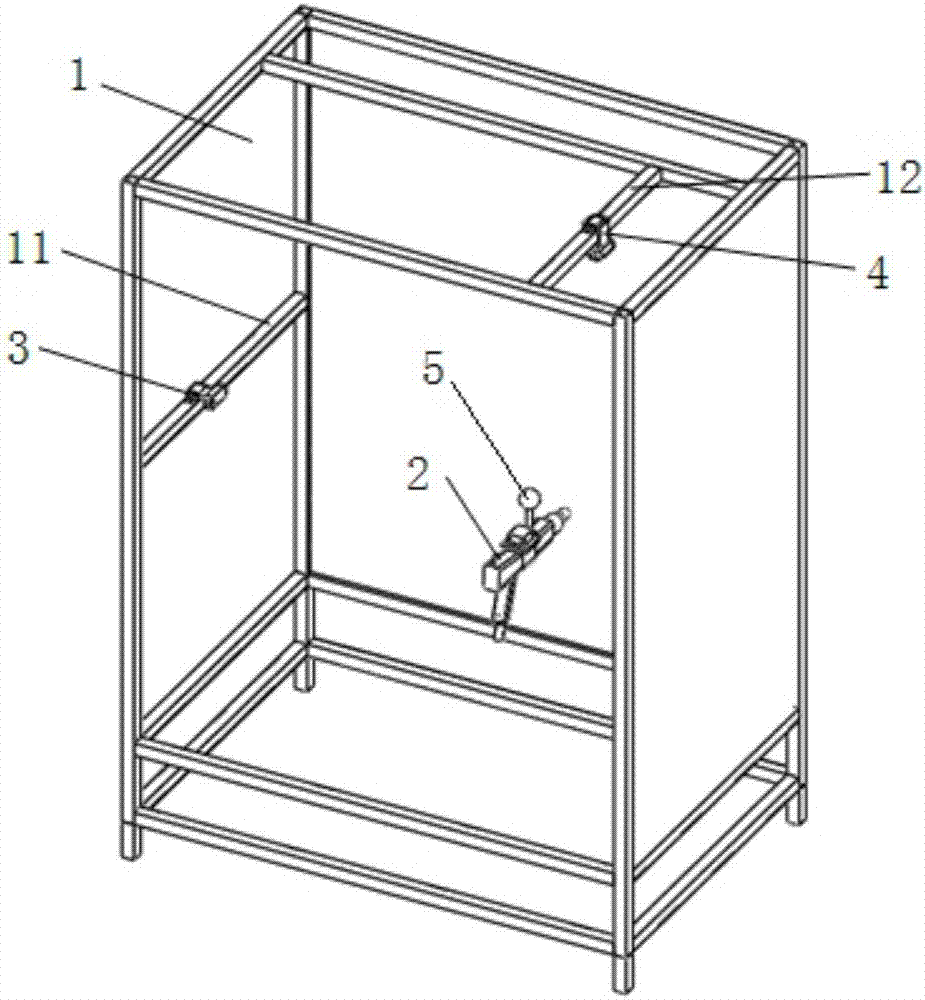

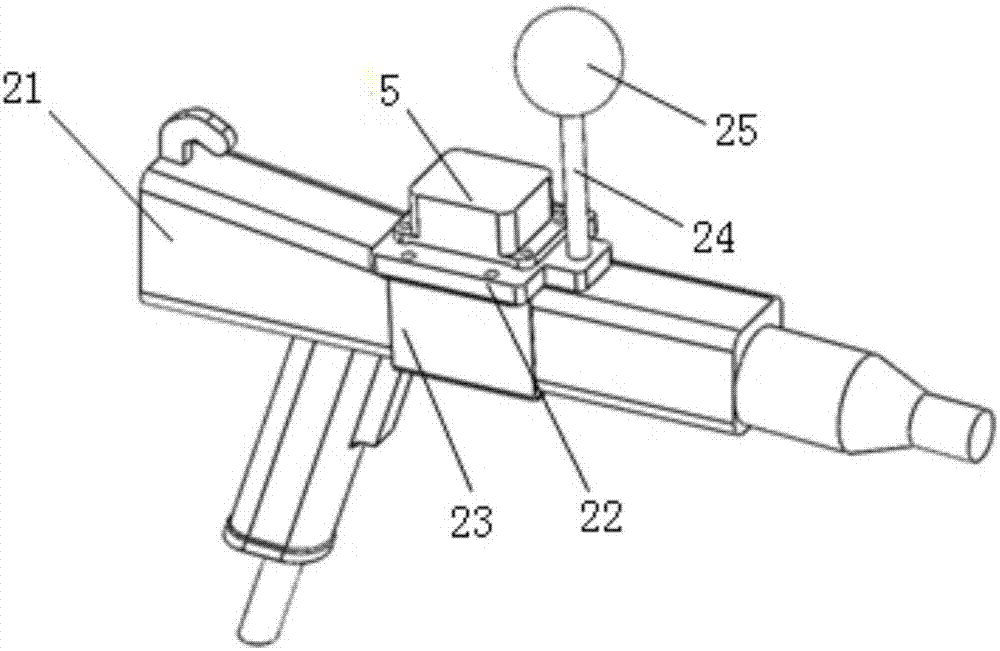

[0021] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

[0022] The present invention provides a spraying teaching device that uses machine vision and an optical fiber gyroscope for positioning. Its working principle is to obtain the coordinate parameters of the spray gun device by using the first camera and the second camera to replace the complicated mechanical mechanism in the prior art. The fiber optic gyroscope obtains the attitude parameters of the spray gun device, and the multi-axis controller obtains the coordinate parameters and attitude parameters to drive the manipulator to reproduce the operation process of the teaching mechanism. The flexibility of the multi-axis manipulator spraying operation mode achieves the purpose of simplifying the structure of the teaching equipment, reducing production costs, improving equipment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com