Aluminum substrate cleaning and paving production line

A production line and aluminum substrate technology, applied in spraying devices, liquid spraying devices, and devices for coating liquid on the surface, etc., can solve problems such as difficulty in framing, affecting work efficiency, and difficulty in aligning upper and lower substrates, so as to improve paving quality and efficiency, improve the effect of spraying quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

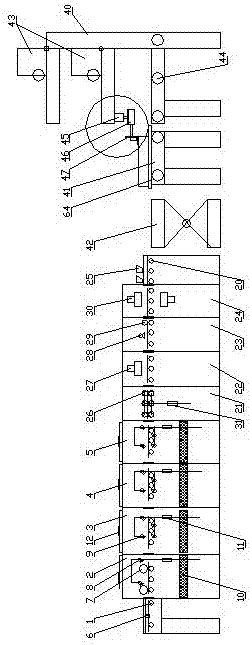

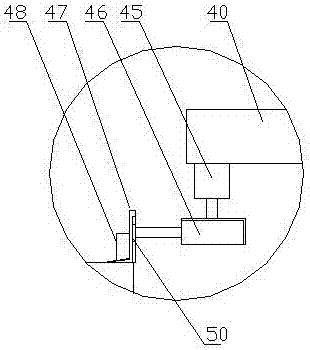

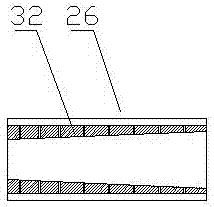

[0012] As shown in the drawings, the present invention includes a conveying roller table 1, a substrate cleaning device, a substrate drying and spraying device, and a substrate paving device. A set of guide rollers 6 are respectively provided on both sides of the conveying roller table 1, and the substrate cleaning device includes a polishing box 2. , The first washing tank 3, the degreasing tank 4 and the second washing tank 5, the substrate drying and spraying device includes a pre-drying box 21, a drying box 22, a glue box 23, a drying box 24 and a pair of air coolers 25, and a conveyor roller 1 Pass through the sanding box 2, the first washing box 3, the degreasing box 4, the second washing box 5, the pre-drying box 21, the drying box 22, the glue box 23 and the drying box 24, and the conveying roller in the grinding box 2 A pair of sanding rollers 7 are arranged above the track, and one set of cooling nozzles 8 are respectively arranged on one side of the pair of sanding ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com