Laminated optoelectronic interconnection printed board and its realization method

A technology of optoelectronic interconnection and realization method, applied in optics, light guides, optical components, etc., can solve problems such as failure of photonic devices, and achieve the effect of overcoming mechanical damage and thermal damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

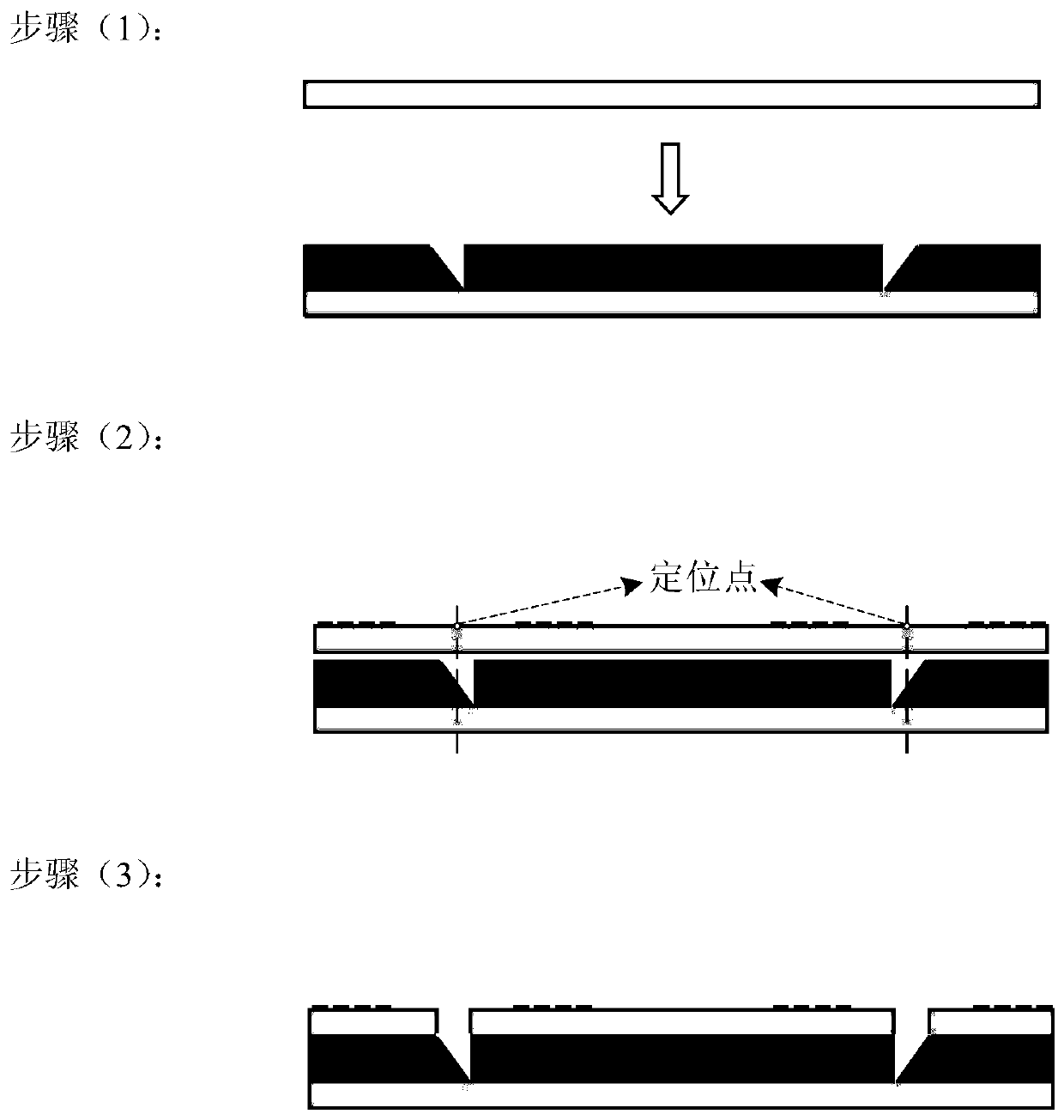

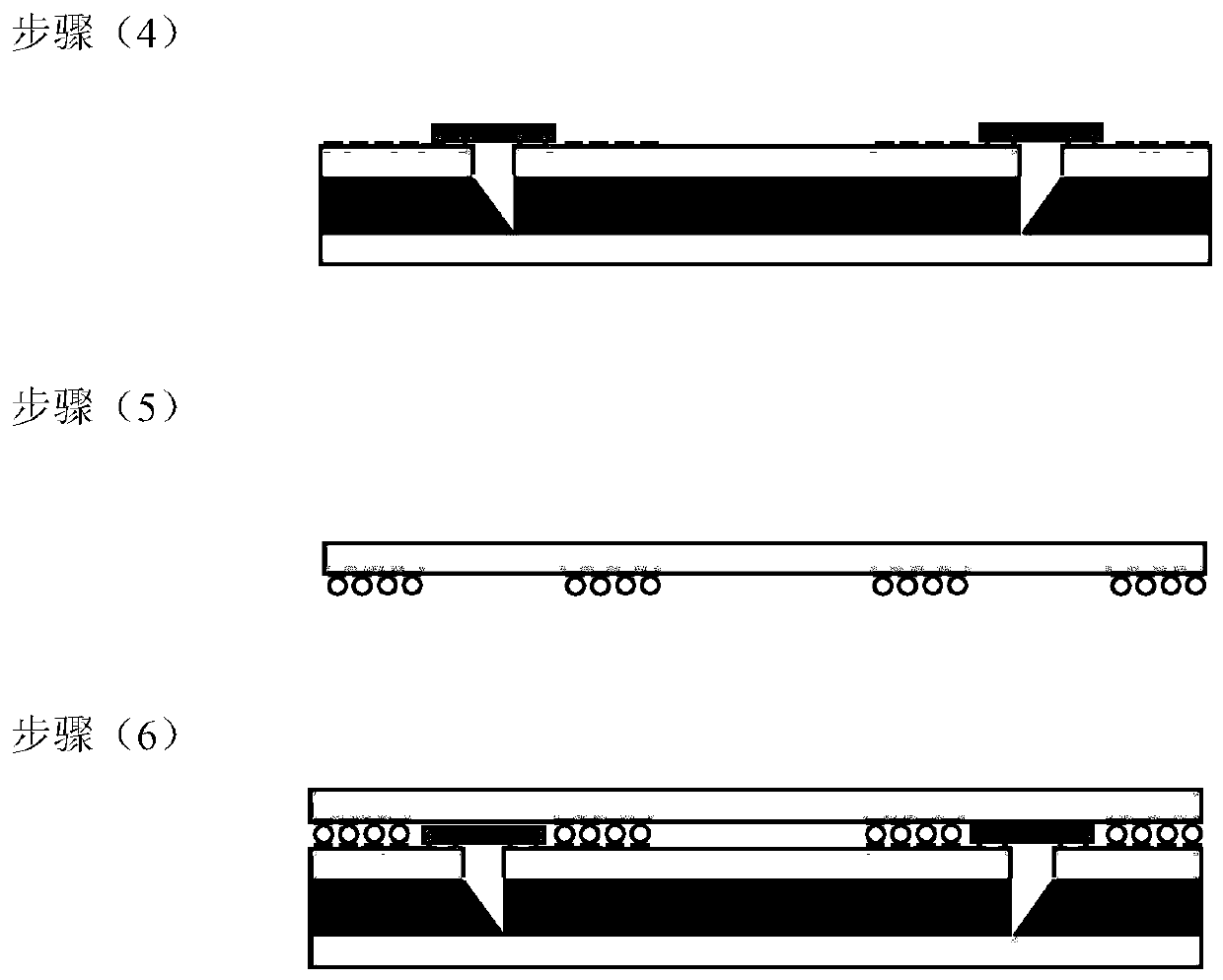

[0032] The present invention will be described in further detail below with reference to the accompanying drawings.

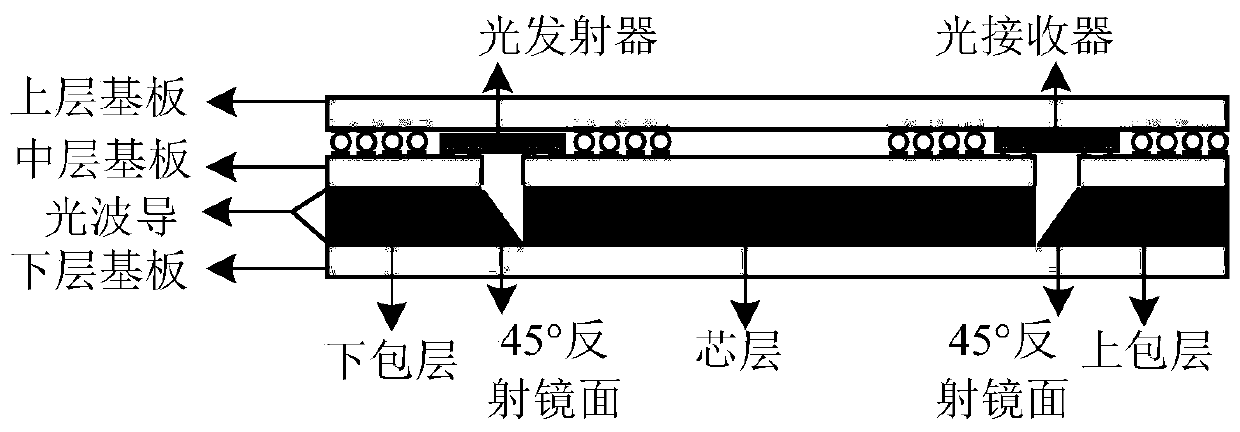

[0033] A laminated photoelectric interconnection printed board, its structure refers to figure 1 , including: upper, middle and lower 3-layer substrate, optical transmitter and optical receiver, polymer optical waveguide. The substrates are all copper clad laminates made of FR4, with a size of 15×5×0.5mm 3 .

[0034] The polymer rectangular optical waveguide is made on the surface of the lower substrate, and the intermediate substrate is pressed on the optical waveguide. The optical waveguide is provided with a 45° reflective micromirror, and the intermediate substrate has a light through hole, which is aligned with the 45° reflective micromirror.

[0035] The light emitter and the light receiver are mounted on the upper surface of the intermediate substrate, and are aligned with the light through hole and the 45° reflective micromirror.

[0036] An array of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com