Amphibious robot applied to submarine cable operational maintenance

A technology for operation and maintenance of submarine cables, which is applied in the installation of cables, amphibious vehicles, and cable installation devices. It can solve the problems of long maintenance time, automation, high efficiency, and high maintenance costs of submarine cables, and achieve good upgradeability. The effect of good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

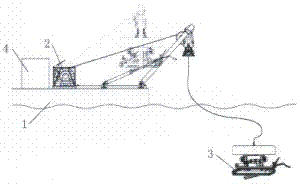

[0023] The system composition of the amphibious robot for submarine cable operation and maintenance mainly includes the underwater carrier system, the surface retractable system, the control system, and the power and auxiliary subsystems.

[0024] 1. Underwater carrier system

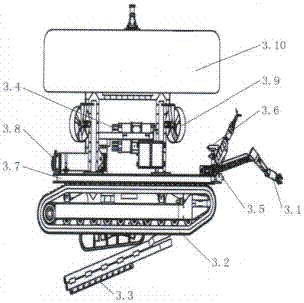

[0025] The underwater carrier system takes the amphibious robot 3 as the main body, and is mainly composed of manipulator 3.1, carrier frame 3.7, buoyancy chamber and ballast 3.10, propulsion system 3.4, power system 3.8, control cabin 3.9, crawler track 3.2, water jet trenching 3.3, It consists of a cable tracker 3.5, an attitude sensor 3.6, a sonar camera and working tools.

[0026] The attitude sensor is used to detect the attitude, depth and crawling heading of the carrier, and the feedback value of these sensors can be used for automatic control. Sonar and camera are used for submarine cable detection and fault inspection, and cable tracker is used for accurate cable burial information acquisition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com