Battery pack

A technology for battery packs and battery cells, applied to battery pack components, circuits, electrical components, etc., can solve the problems of lack of safety protection structure, unstable battery pack structure, etc., and achieve the effect of reducing or eliminating expansion or compression deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

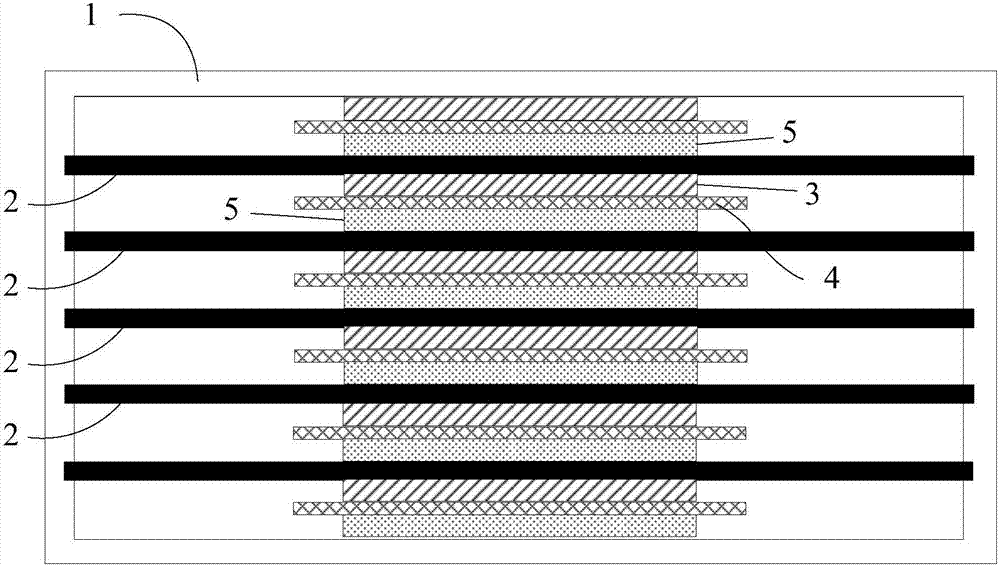

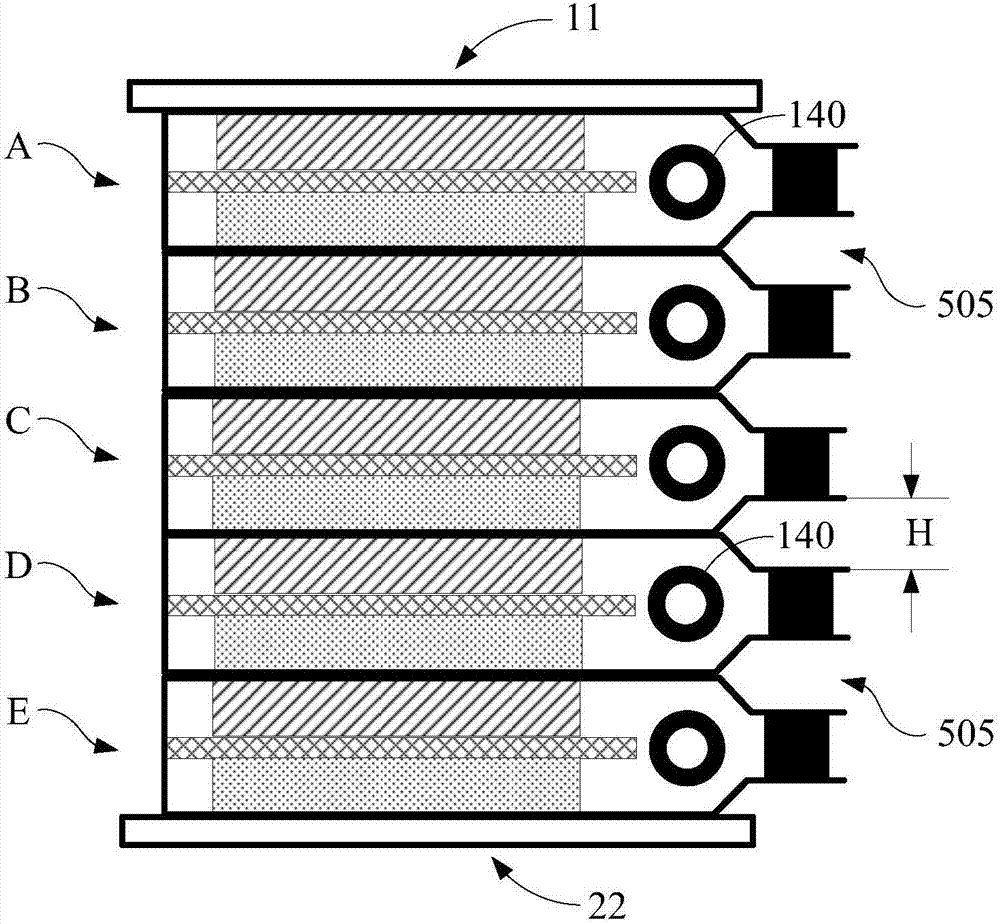

[0038] see figure 2 , figure 2 It is a structural schematic diagram of the first embodiment of the battery pack of the present invention; the battery pack in this embodiment includes 5 battery cells (A, B, C, D, E), of course, in other embodiments, the number of battery cells is not the same as Not limited to 5, can be 2, 3, 4, 6... or more. The exact number depends on the output voltage requirements of the battery. Multiple battery cells connected in series can form a battery pack with a specified output voltage.

[0039] The outside of the battery pack is the upper and lower end plates (11, 22), and the upper and lower end plates (11, 22) can be metal collector plates, which function to conduct electricity and provide external support, so they need to be conductive and have Certain mechanical strength. In addition, the upper and lower end plates (11, 22) can also be support plates for forming the casing of the battery pack. The upper and lower end plates (11, 22) can ...

Embodiment 2

[0051] It should be noted that in the subsequent embodiments, only the structural differences from the first embodiment will be emphasized, and the same or similar structural features will not be described in detail.

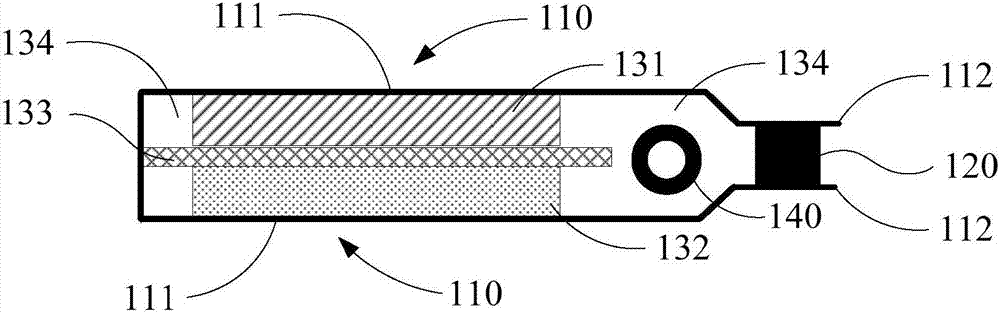

[0052] see Figure 4 , Figure 4 It is a structural schematic diagram of the second embodiment of the battery pack of the present invention. The battery pack in this embodiment also includes 5 battery cells A, B, C, D, and E. The difference from the previous embodiment is that in this embodiment Both ends of the metal plate of the battery cell are provided with separation areas, and a seal is provided between the separation areas of the two metal plates of the same battery cell. This structure can form more gaps 505 between the separation areas, thus further improving the Compared with the structure in Example 1, the expansion resistance coefficient of the battery cell is doubled. In addition, an elastic buffer 140 is added to further enhance the expansion res...

Embodiment 3

[0056] see Figure 8 , Figure 8 It is a structural schematic diagram of the third embodiment of the battery pack of the present invention. Compared with Embodiment 1, in this embodiment, an elastic support body 506 is provided between the adjacent metal plates of adjacent battery cells at the same end separation area, which is equivalent to Since the elastic support body fills the original gap 505 , the elasticity of the elastic support body 506 can enhance the extensibility of the stacking direction of the battery pack. Any suitable material can be used for the elastic support body 506 . For example, materials such as silicone rubber, EPDM rubber, polyethylene, and polyvinyl chloride have the following characteristics: good insulation, can coexist with electrolytes, and can be stable at voltages below 10 volts and below 200 degrees. Preferably, the elastic support body can increase the elastic deformation by at least 15% or more in the stacking direction of the battery cel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com