Composite nonwoven cloth as well as preparation method and application thereof

A non-woven, usage-amount technology, applied in the field of air purification, can solve the problems of low efficiency, loss of functionality, difficult to effectively eliminate air pollution, etc., and achieve the effect of high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

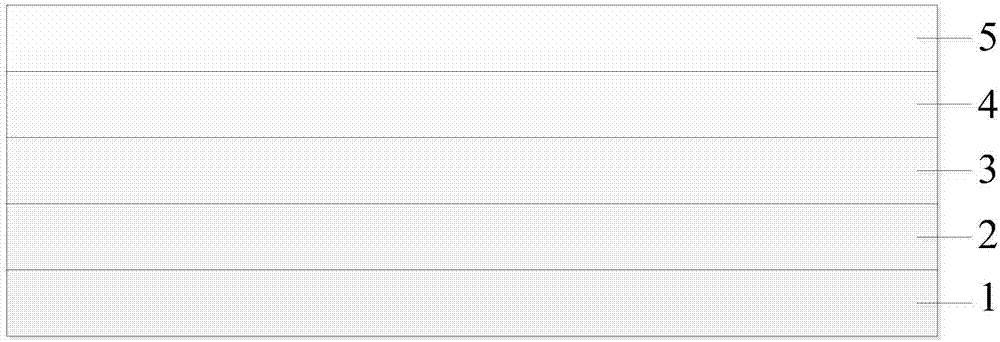

[0049] A composite non-woven fabric, such as figure 1 As shown, it includes a support layer 1, a fixed film layer 2 on the support layer 1, a granular filter material layer 3 on the fixed film layer 2, a functional layer 4 on the granular filter material layer 3 and a functional layer Protective layer 5 on layer 4.

[0050] Among them, the support layer is 70g / m 2 Polyester ultra-short fiber non-woven fabric; the fixed film layer is 20g / m 2 Environmentally friendly mucous membrane; the particles in the granular filter material layer are modified diatomite particles, specifically diatom particles loaded with nano-titanium dioxide chelated platinum catalyst, spherical in shape, with an average diameter of 0.8mm, and a usage amount of 250g / m 2 ;The functional layer is 25g / m 2 Melt-blown non-woven fabric; the protective layer is 30g / m 2 synthetic fiber non-woven fabrics;

[0051] The preparation method comprises the following steps:

[0052]1) Upper film: Fix the film layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com