Flour paste soup preparation equipment for dining hall

A technology of white soup and batter, applied in the direction of mixer, dissolving, mixing methods, etc., to achieve the effect of avoiding food waste, avoiding air pollution, and enhancing taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

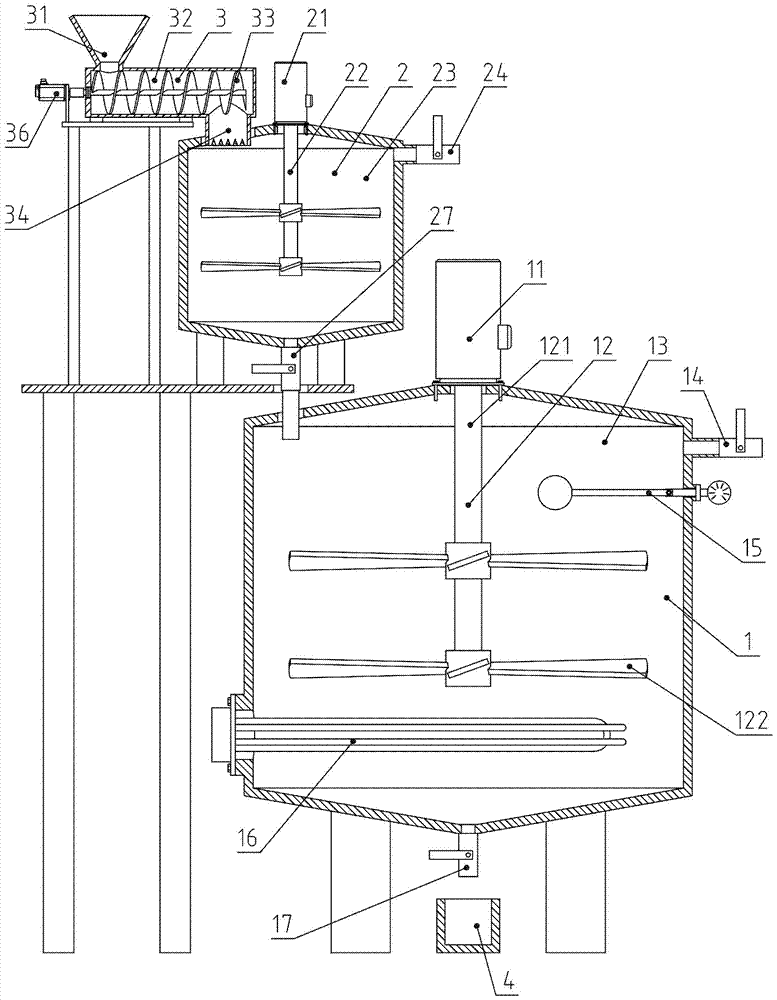

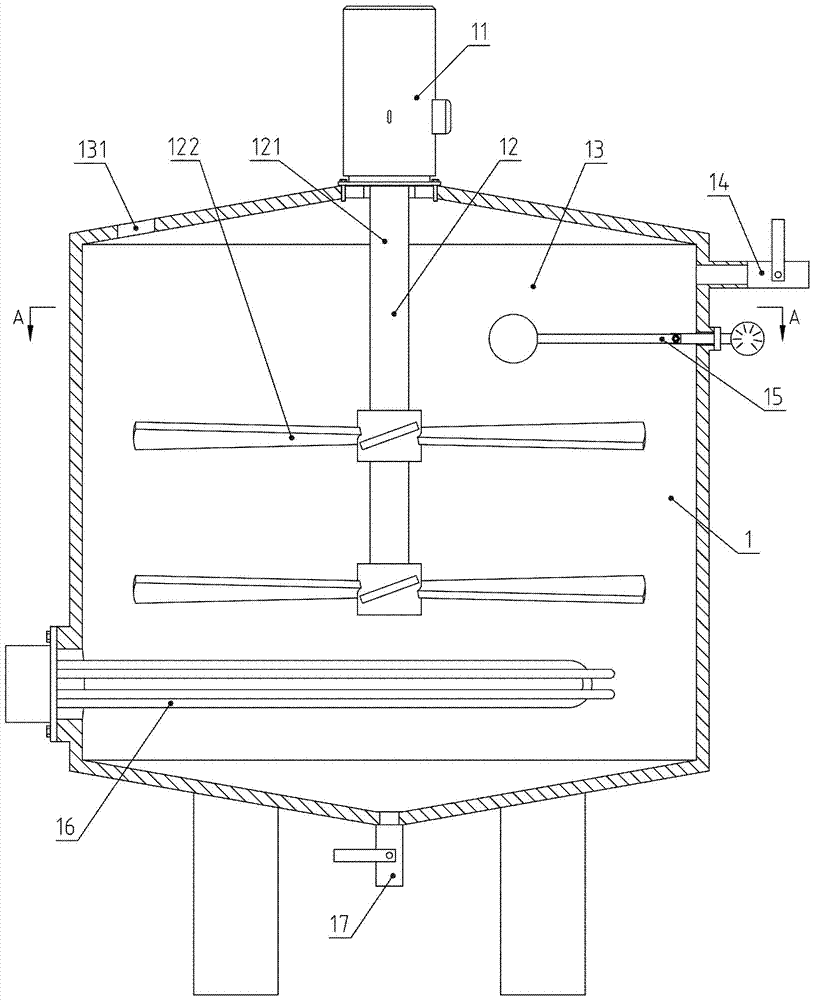

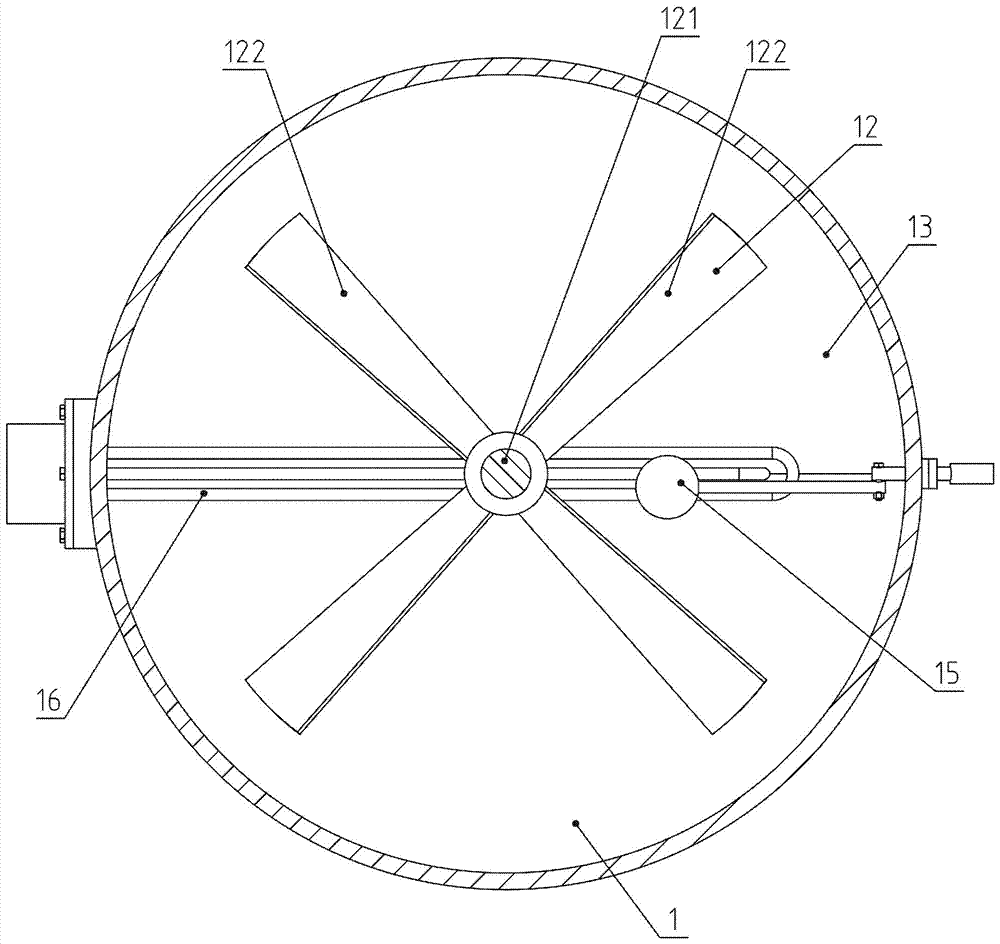

[0031] Example: see Figure 1 to Figure 7 .

[0032] A kind of white soup preparation equipment for canteens, including a white soup cooking tank 1, a batter mixing tank 2 and a flour sprinkler 3;

[0033] Flour sprinkler 3 comprises flour hopper 31, horizontal cylinder 32, propulsion screw 33, flour outlet 34, grate teeth 35 and propulsion motor 36, horizontal cylinder 32 is fixedly connected with frame, and the shell flange of propulsion motor 36 and machine The frame is fixedly connected, the center line of the horizontal cylinder 32 is horizontal, and the axis line of the propulsion screw 33 is horizontal, installed inside the horizontal cylinder 32, and forms a rotating pair with the horizontal cylinder 32, the output shaft of the propulsion screw 33 and the propulsion motor 36 Fixedly connected; the lower mouth of the flour hopper 31 communicates with the feed end of the horizontal cylinder 32; the discharge end of the horizontal cylinder 32 has a flour outlet 34 with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com