Dispersing method for zero-valent iron

A zero-valent iron, dispersion technology, applied in the field of environmental engineering and environmental geotechnical engineering, can solve the problems of high cost of dispersants, easy oxidation, easy aggregation of zero-valent iron particles, etc., to achieve low price, increase consistency, and reduce usage volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

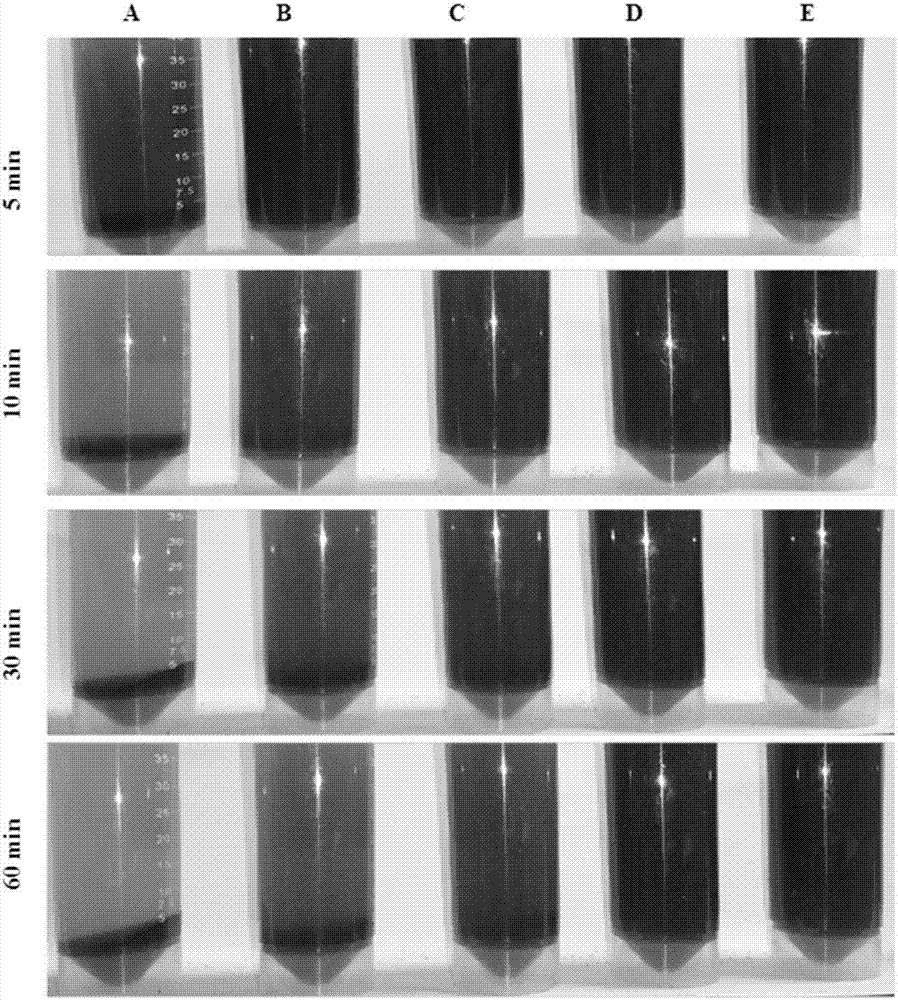

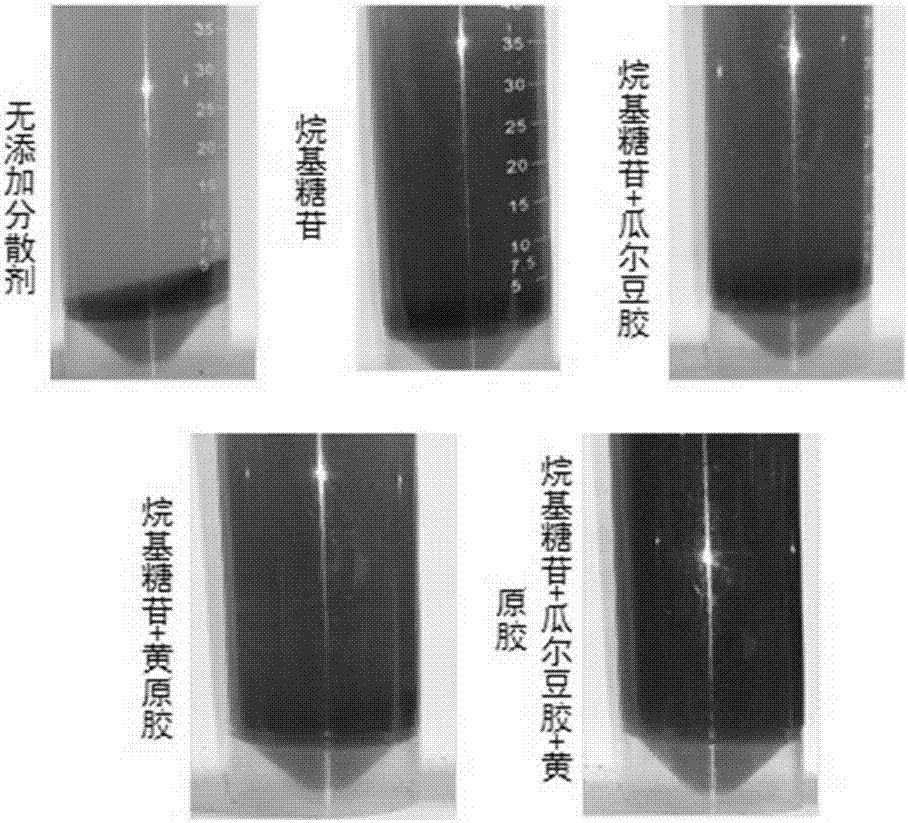

[0057] Example 1 Adding different components and different ratios of dispersants, the dispersion effect test of nanometer zero-valent iron in aqueous ethanol solution.

[0058] (1) Weigh FeSO with a balance 4 ·7H 2 O 12.5g, dissolved in 100ml deoxygenated deionized water, transferred to a 500ml three-necked flask, and protected by nitrogen gas.

[0059] (2) Weigh NaBH 4 1.9g, dissolved in 100ml deoxygenated deionized water.

[0060](3) Under the conditions of mechanical stirring (r=200r / min) and nitrogen protection, the solution in step (2) was added dropwise to the solution in step (1) at a rate of 2 drops / min.

[0061] (4)BH 4 - Continue to react for 30 minutes after the solution is dripped, wash with deionized water and absolute ethanol for 2 to 3 times respectively, and separate zero-valent iron particles by magnetic separation, and store them in 50ml of ethanol aqueous solution, wherein the volume ratio of ethanol and water is 1:4, the mass fraction of elemental ir...

Embodiment 2

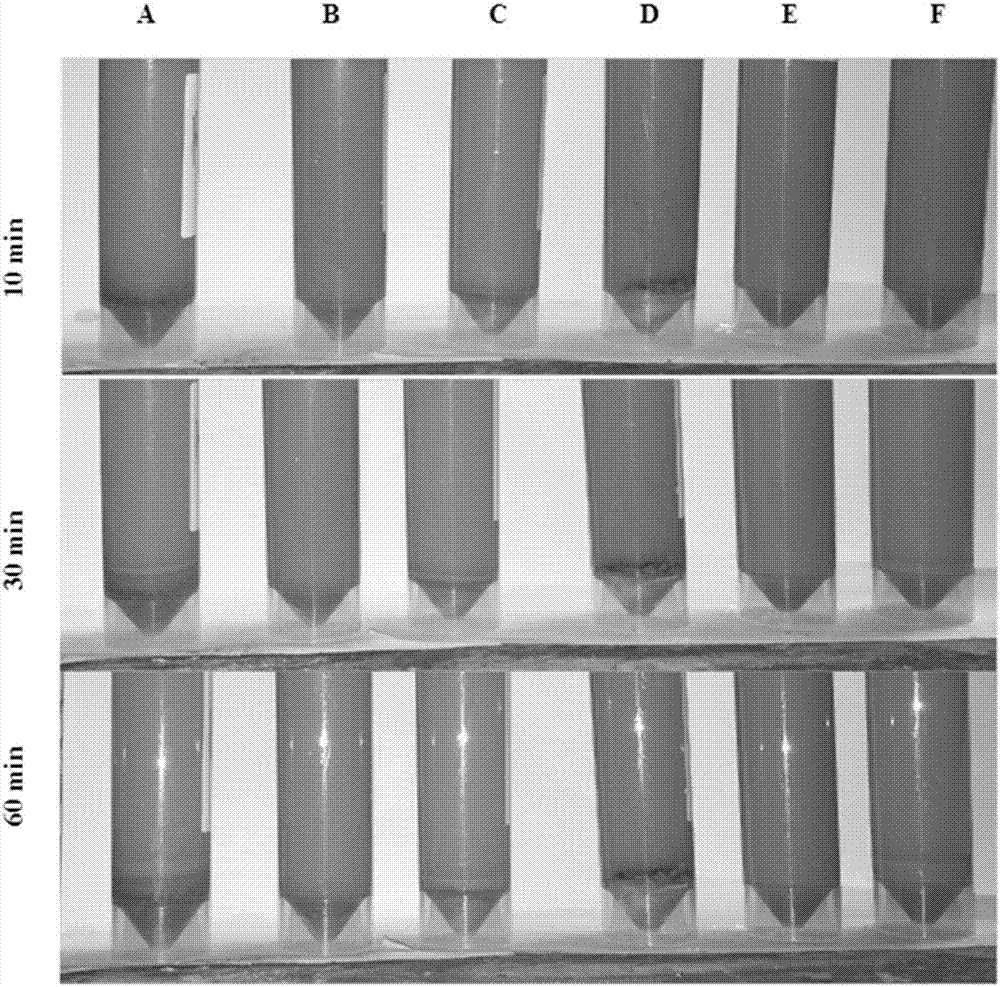

[0066] Example 2 Adding different components and different ratios of dispersants, the dispersion effect test of micron zero-valent iron in the mixed system of bentonite and water.

[0067] (1) Weigh 4.0g of commercial micron iron powder (Daramend iron powder) into a 50ml centrifuge tube, add deoxygenated deionized water to the 50ml mark.

[0068] (2) Weigh 20.0 g of bentonite and add it to the centrifuge tube of step (1).

[0069] (3) Steps 1 to 2 were repeated six times to obtain micron zero-valent iron-bentonite water systems numbered A, B, C, D, E, and F.

[0070] (4) Add 2.0g of alkyl glycosides + 20g of deionized water, 1.0g of xanthan gum + 1.0g of alkyl glycosides + 20g of deionized water, 1.0g of guar beans to B, C, D, E, and F respectively. Gum + 1.0g alkyl glucoside + 20g deionized water, 1.0g guar gum + 0.6g xanthan gum + 0.4g alkyl glycoside + 20g deionized water, 1.2g guar gum + 0.4g xanthan gum + 0.4g alkyl glycoside + 20g deionized water, add 20g deionized wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com