Ball screw of engraving-milling machine

A ball screw, engraving and milling machine technology, applied in the direction of metal processing machinery parts, metal processing, metal processing equipment, etc., can solve the problem that the ball screw does not have cleaning and dust, achieve high reversibility, high efficiency, and improve precision and quality, novel effect of structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

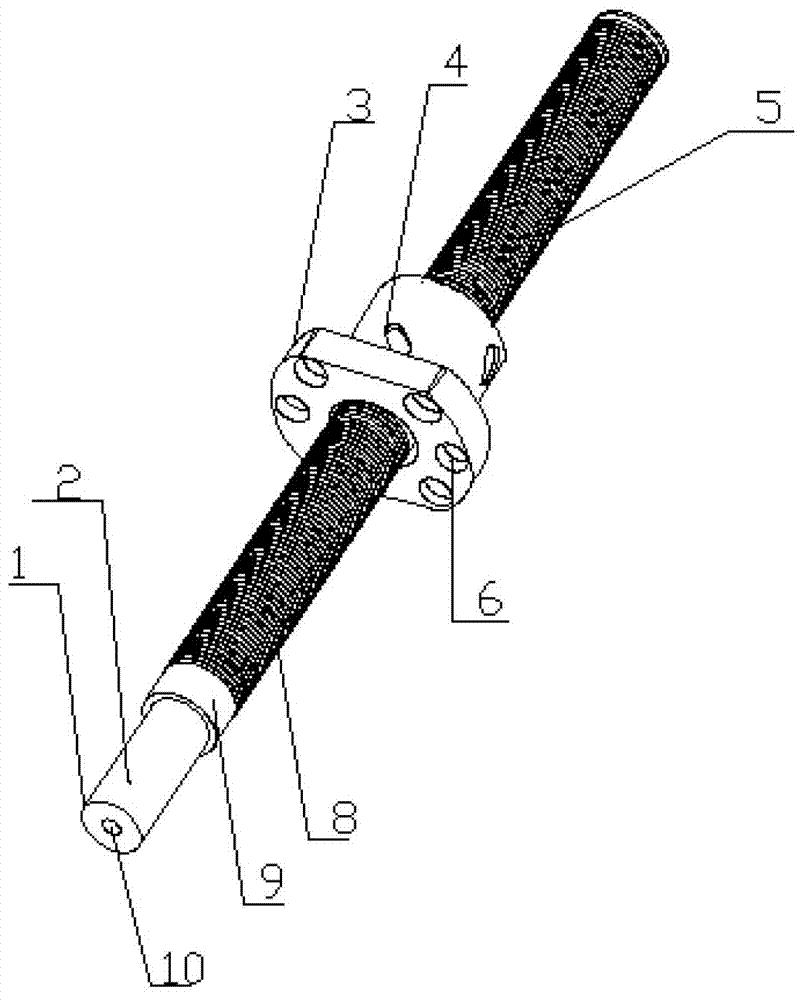

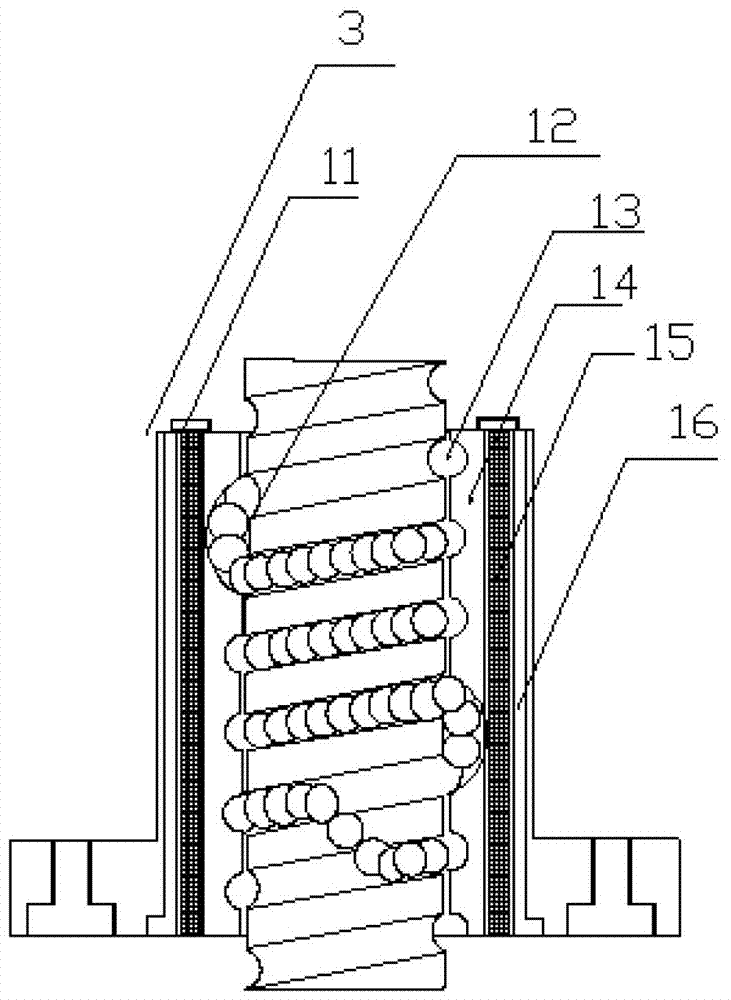

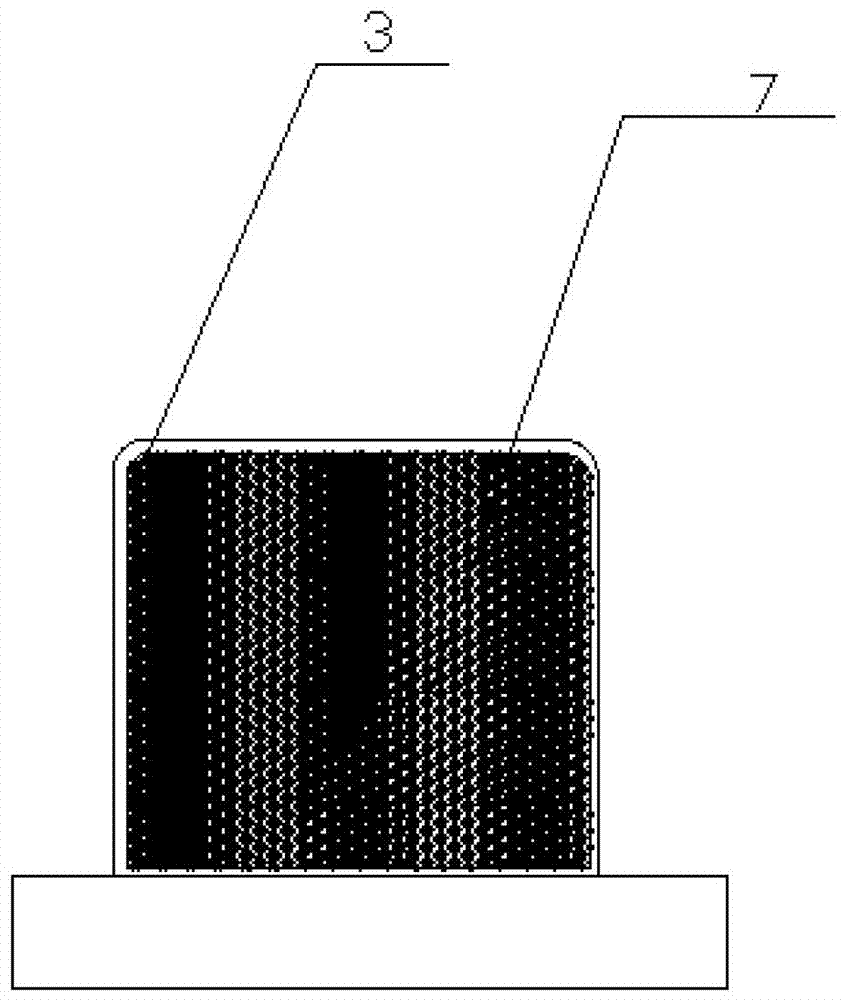

[0019] Such as Figure 1-3 As shown, the present invention provides a ball screw for engraving and milling machine, the rod body 1 is provided with a threaded rod 5, one end of the threaded rod 5 is provided with a shaft sleeve installation position 9, and one end of the shaft sleeve installation position 9 is provided with a processing shaft end 2, A screw hole 10 is provided on the processing shaft end 2, a threaded structure 8 is provided on the surface of the threaded rod 5, a nut 3 is provided on the threaded rod 5, a reverser 4 is provided on the nut 3, and one end of the nut 3 is provided with The countersunk hole 6 is installed on the flange, and the inside of the nut 3 is provided with a groove 13, one end of the groove 13 is provided with an inner wall 14, one end of the inner wall 14 is provided with an electrostatic sheet 15, and the top of the electrostatic sheet 15 is provided with a clamping shaft 11, One end of the electrostatic sheet 15 is provided with a holl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com