OCA optical cement and OCA optical cement film

An optical glue and unsaturated technology, applied in the field of optical glue, can solve the problems of lower yield rate of OCA film, poor adhesion and peelability, poor wettability, etc., and achieve excellent wettability and excellent performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

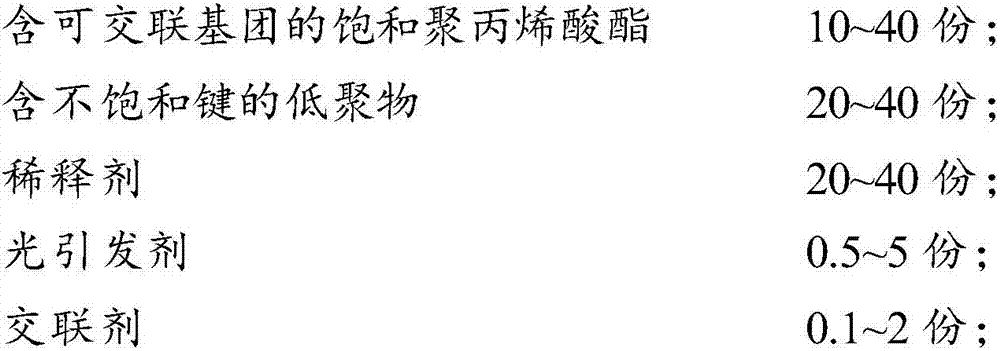

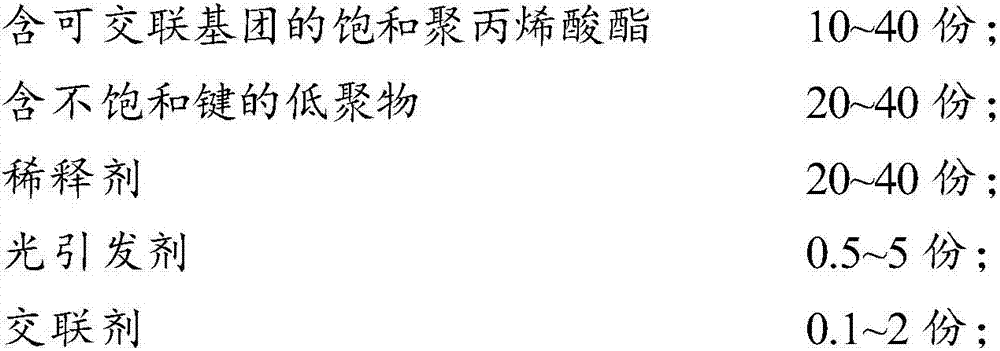

[0047] 1) Composition design

[0048] The composition of the OCA optical glue provided by the embodiment of the present invention is shown in the following table:

[0049] The composition of table 1 embodiment OCA optical glue

[0050]

[0051]

[0052] 2) film preparation

[0053] According to the proportions in Table 1, the components were mixed evenly to obtain the OCA optical adhesives provided in the four examples, which were named OCA optical adhesive 1, OCA optical adhesive 2, OCA optical adhesive 3, and OCA optical adhesive 4.

[0054] Use a slit coater to coat the OCA optical glue on the release film, first use a mercury lamp to cure with ultraviolet light, and the energy of ultraviolet light is 2000mJ / cm 2 , and then baked in an oven at 180°C for 5 minutes to obtain OCA optical adhesive films with a thickness of 200 μm, which were named OCA optical adhesive film 1, OCA optical adhesive film 2, OCA optical adhesive film 3, and OCA optical adhesive film 4.

Embodiment 5

[0056] With reference to the preparation method of Example 3, the only difference is that the energy of the ultraviolet light is adjusted to 2000mJ / cm 2 , the oven temperature was adjusted to 120°C, and the baking time was adjusted to 10 minutes to prepare an OCA optical adhesive film with a thickness of 200 μm, which was named OCA optical adhesive film 5.

Embodiment 6

[0058] With reference to the preparation method of Example 3, the only difference is that the energy of the ultraviolet light is adjusted to 3000mJ / cm 2 , the oven temperature was adjusted to 90°C, and the baking time was adjusted to 10 minutes to prepare an OCA optical adhesive film with a thickness of 200 μm, which was named OCA optical adhesive film 6.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com