Method for preparing water coal semicoke grout by coal dust filling modification and grading technology

A semi-coke and modification technology, which is applied in the field of coal powder filling modification and grading technology to prepare water-coal semi-coke slurry, can solve the problem that the clean and efficient utilization of semi-coke cannot be solved, the void structure of semi-coke is not improved, and the energy utilization efficiency is low. and other problems, to achieve the effect of good industrial application prospects, improved performance, and simple pulping process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

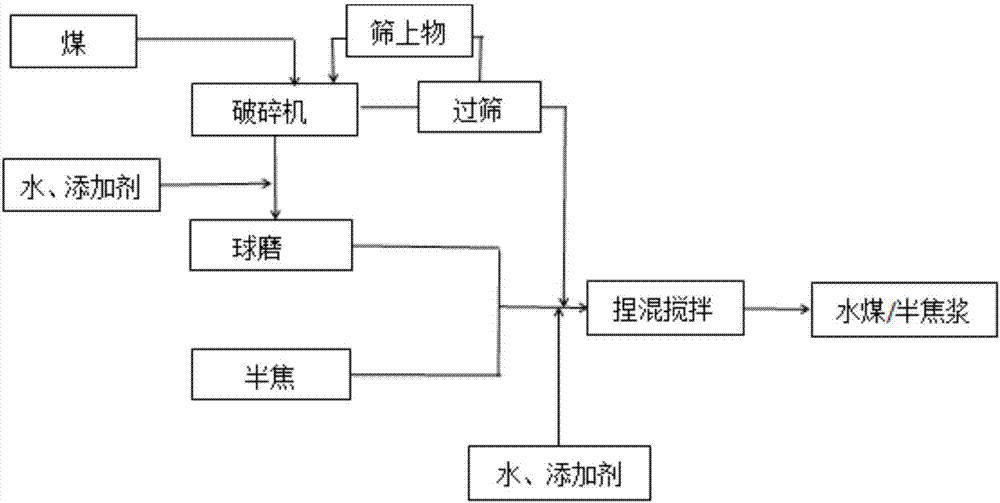

Embodiment 1

[0020] see figure 1 As shown, the dry basis ratio of coarse coal powder, fine powder and semi-coke is 40:40:20, and the dry basis dosage of dispersant accounts for 5‰ of the total dry basis. The coal is crushed by a jaw crusher and passed through a 14-mesh sieve to obtain a coarse powder, and the coal on the sieve is ball-milled to obtain a fine coal slurry. Weigh 144.6g Yankuang coal fine slurry (52.6% concentration, 25.3μm average particle size), add 3.2g 30% dispersant and 38.1g water, add 38.0g dried semi-coke and 76.1g water while stirring g Yankuang coal coarse powder, after the feeding is completed, stir quickly for 10 minutes to prepare the water coal / semi-coke slurry filled with modified Xinjiang semi-coke with Yankuang coal grading. Weigh 143.2g Zhundong coal fine slurry (47.6% concentration, average particle size 23.4μm), add 2.8g 30% dispersant and 51.7g water, add 34.1g dried semi-coke and 68.2 g Zhundong coal coarse powder, after the addition of materials, stir...

Embodiment 2

[0025] see figure 1 As shown, the dry basis ratio of coarse coal powder, fine powder and semi-coke is 40:30:30, and the dry basis dosage of dispersant accounts for 8‰ of the total dry basis. The coal is crushed by a jaw crusher and passed through a 14-mesh sieve to obtain a coarse powder, and the coal on the sieve is ball-milled to obtain a fine coal slurry. Weigh 121.4g Pingyi coal fine slurry (42.2% concentration, average particle size 19.3μm), add 4.5g 30% dispersant and 54.6g water, add 51.2g dried semi-coke and 68.3g Pingyi Coal Coarse Powder, after the feeding is completed, stir rapidly for 10 minutes to prepare Pingyi Coal graded filled modified Inner Mongolia semi-coke water coal / semi-coke slurry. Weigh 121.6g Erlin rabbit coal fine slurry (concentration is 41.3%, average particle size 18.7μm), then add 4.5g 30% dispersant and 56.7g water, add 50.2g dried semi-coke and 67.0g while stirring g Erlin Rabbit Coal Coarse Powder, and then quickly stir for 10 minutes after ...

Embodiment 3

[0030] see figure 1As shown, the dry basis ratio of coarse coal powder, fine powder and semi-coke is 40:35:25, and the dry basis dosage of dispersant accounts for 7‰ of the total dry basis. The coal is crushed by a jaw crusher and passed through a 14-mesh sieve to obtain a coarse powder, and the coal on the sieve is ball-milled to obtain a fine coal slurry. Weigh 147.8g of Daliuta coal fine slurry (40.5% concentration, 22.3μm average particle size), add 4.0g 30% dispersant and 37.0g water, add 42.8g dried semi-coke and 68.4 g Daliuta coal coarse powder, after the addition of the material, stir rapidly for 10 minutes to prepare the water coal / semi-coke slurry filled with modified Shaanxi semi-coke with Daliuta coal grading. Weigh 138.2g Yulin coal fine slurry (concentration is 43.7%, average particle size 21.4μm), add 4.0g 30% dispersant and 45.7g water, add 43.1g dried semi-coke and 69.0g Yulin coal coarse powder was stirred rapidly for 10 minutes after the feeding was compl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com