Method for producing ultra-low carbon steel through RH complex deoxidation

A technology of ultra-low carbon steel and composite deoxidation, which is applied in the field of steelmaking in the metallurgical industry to avoid nodules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

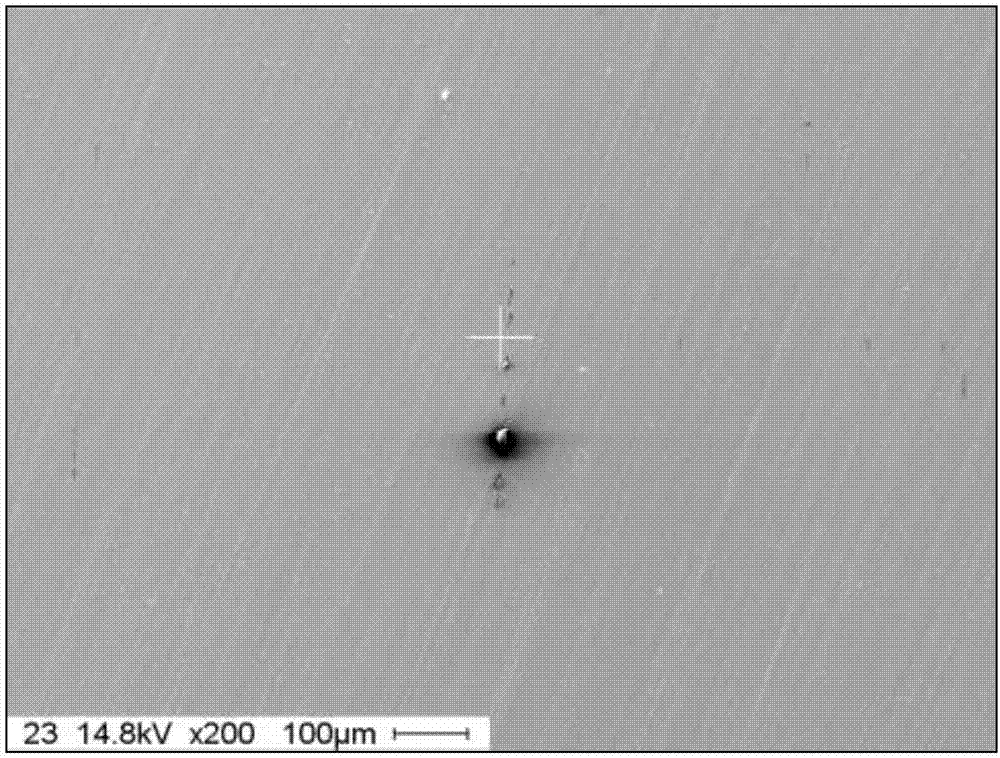

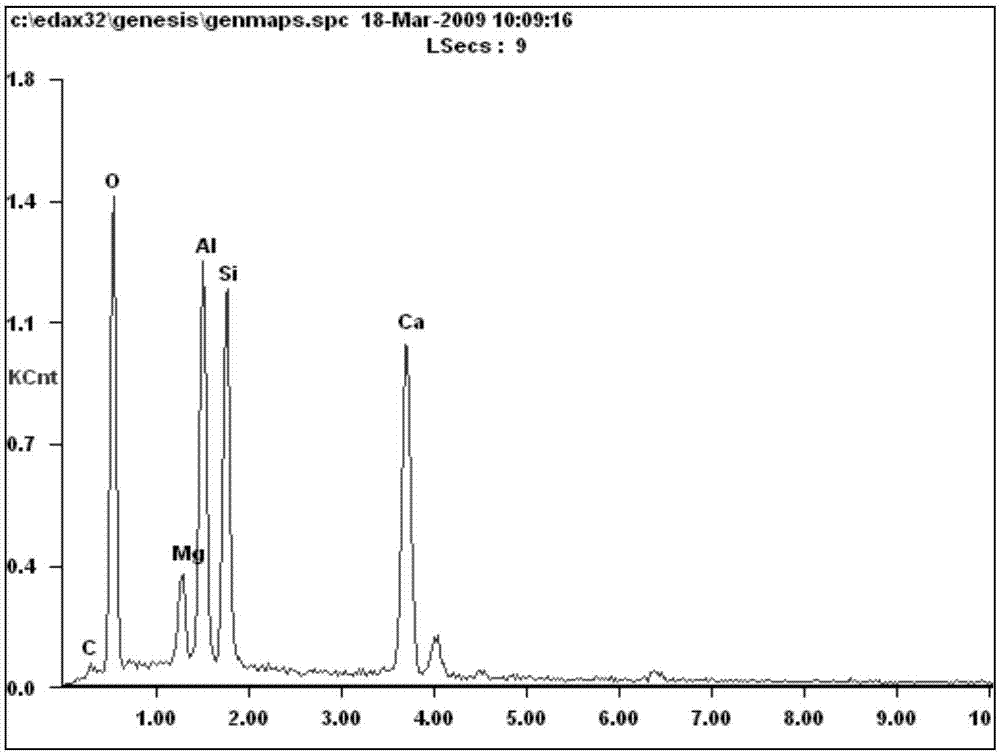

Image

Examples

Embodiment 1

[0055] (1) Pretreatment of molten iron: desulfurization by spraying method, slag removal after desulfurization, and control of sulfur content in molten iron after desulfurization to 0.002%.

[0056] (2) Converter smelting: use 260t top-bottom combined blowing converter smelting, control the carbon content of molten steel tapping: 0.03%, control the oxygen content in steel: 900ppm, control the end point temperature of molten steel: 1690°C, and control the temperature of the ladle top after tapping The slag is added into high alumina balls for modification treatment;

[0057] (3) RH vacuum treatment: the oxygen content in the steel is 900ppm, and the natural decarburization method is adopted, that is, the RH furnace does not blow oxygen. After decarburization, the carbon content in the steel is controlled at 10ppm.

[0058] After decarburization in the RH refining furnace, add silicon calcium magnesium deoxidizer 0.12kg / t steel first, and then add aluminum for deoxidation after...

Embodiment 2

[0062] (1) Hot metal pretreatment: Desulfurization by injection method, slag removal after desulfurization, and control of sulfur content in hot metal after desulfurization to 0.003%.

[0063] (2) Converter smelting: use a 260t top-bottom combined blowing converter to smelt, control the carbon content of the molten steel: 0.02%, control the oxygen content in the steel: 1000ppm, control the end point temperature of the molten steel: 1700°C, and place the steel on the top of the ladle after tapping. The slag is added into high alumina balls for modification treatment;

[0064] (3) RH vacuum treatment: the oxygen content in the steel is 1000ppm, and the natural decarburization method is adopted, that is, the RH furnace does not blow oxygen. After decarburization, the carbon content in the steel is 9ppm.

[0065] After the decarburization of the RH refining furnace is completed, 0.15 kg / t of silicon calcium magnesium deoxidizer is added first, and then aluminum is added for deoxi...

Embodiment 3

[0069] (1) Hot metal pretreatment: Desulfurization by injection method, slag removal after desulfurization, and control of sulfur content in hot metal after desulfurization to 0.003%.

[0070] (2) Converter smelting: use a 260t top-bottom combined blowing converter to smelt, control the carbon content of the molten steel: 0.06%, control the oxygen content in the steel: 500ppm, control the end point temperature of the molten steel: 1680°C, and place the steel on the top of the ladle after tapping. The slag is added into high alumina balls for modification treatment;

[0071] (3) RH vacuum treatment: If the oxygen content in the steel is 500ppm, the forced oxygen blowing method is adopted, that is, oxygen is blown into the RH furnace. After decarburization, the carbon content in the steel is 8ppm.

[0072] After decarburization in the RH refining furnace, add silicon calcium magnesium deoxidizer 0.18kg / t steel first, and then add aluminum for deoxidation after 2 minutes.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com