Axial-flow fan blade with high noise elimination degree

An axial-flow fan blade and high-noise technology, which is applied to components of pumping devices for elastic fluids, non-variable pumps, machines/engines, etc., can solve the impact of axial-flow fan blade operation and noise control, shaft The data parameters of the airflow blades are very high, and the low-noise performance of the blades needs to be further improved to achieve the effect of reducing the amount of noise and reducing the noise level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

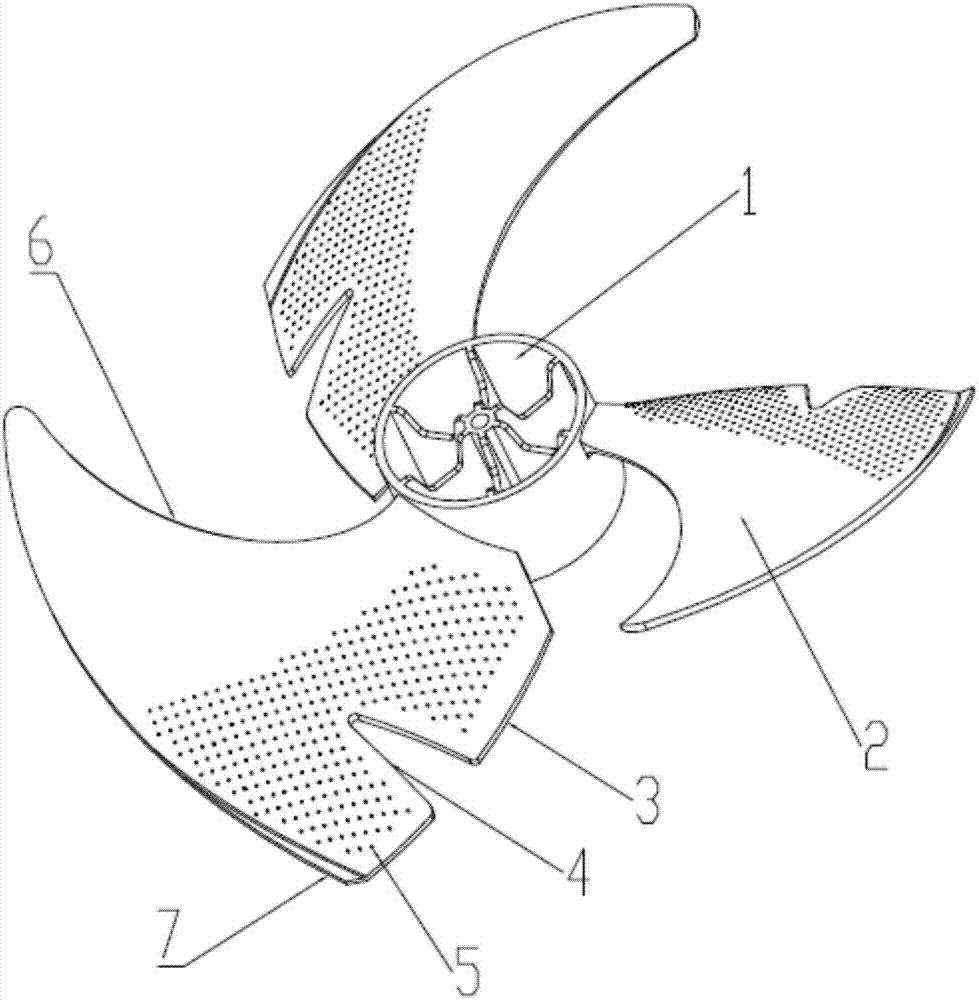

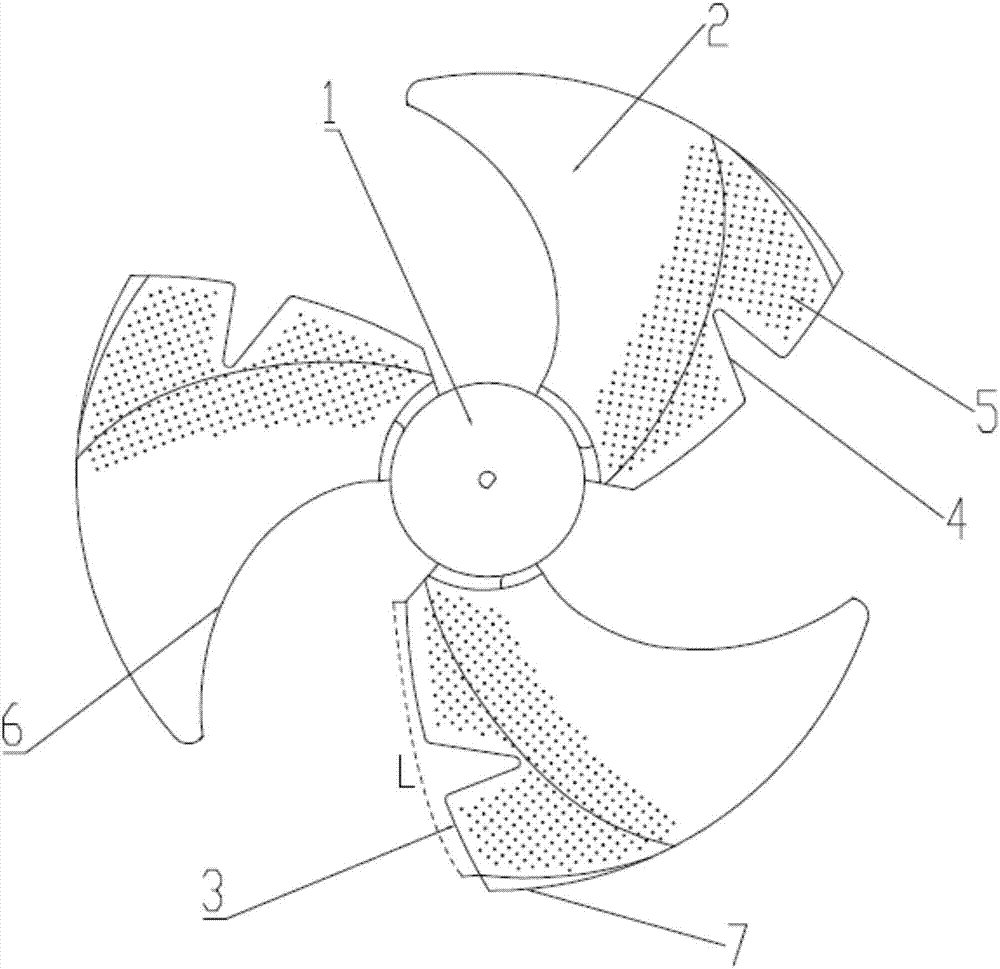

[0015] see figure 1 As shown, the present invention provides a high-noise elimination axial-flow fan blade, including a hub 1 and a blade 2 arranged on the side of the hub 1, the middle part of the trailing edge 3 of the blade 2 is provided with a blade extending toward the central area of the blade 2 V-shaped groove 4, the length of the sideline of the trailing edge 3 is assumed to be L, the starting point of the V-shaped groove 4 on the trailing edge 3 is located at the length of 0.55-0.64L of the sideline of the trailing edge 3, and the V-shaped groove 4 is at the trailing edge The end point on 3 is located at the length of 0.7-0.78L of the sideline of trailing edge 3, and the depth of V-shaped groove 4 is 0.4-0.65L; the blades 2 on both sides of V-shaped groove 4 are densely arranged with multiple miniature noise reduction devices. The h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com