Electric coupler pulling-out force testing device and method thereof

An electrical connector and testing device technology, which is applied in the direction of accumulator device, fluid pressure actuating device, measuring device, etc., can solve the problem that the connector pull-off force testing device does not involve water pressure environment and cannot test underwater connectors. Transient pull-off force, inability to meet the actual working conditions of pull-off force, etc., to achieve the effect of strong human-computer interaction ability, friendly interface, and large stepless speed regulation range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

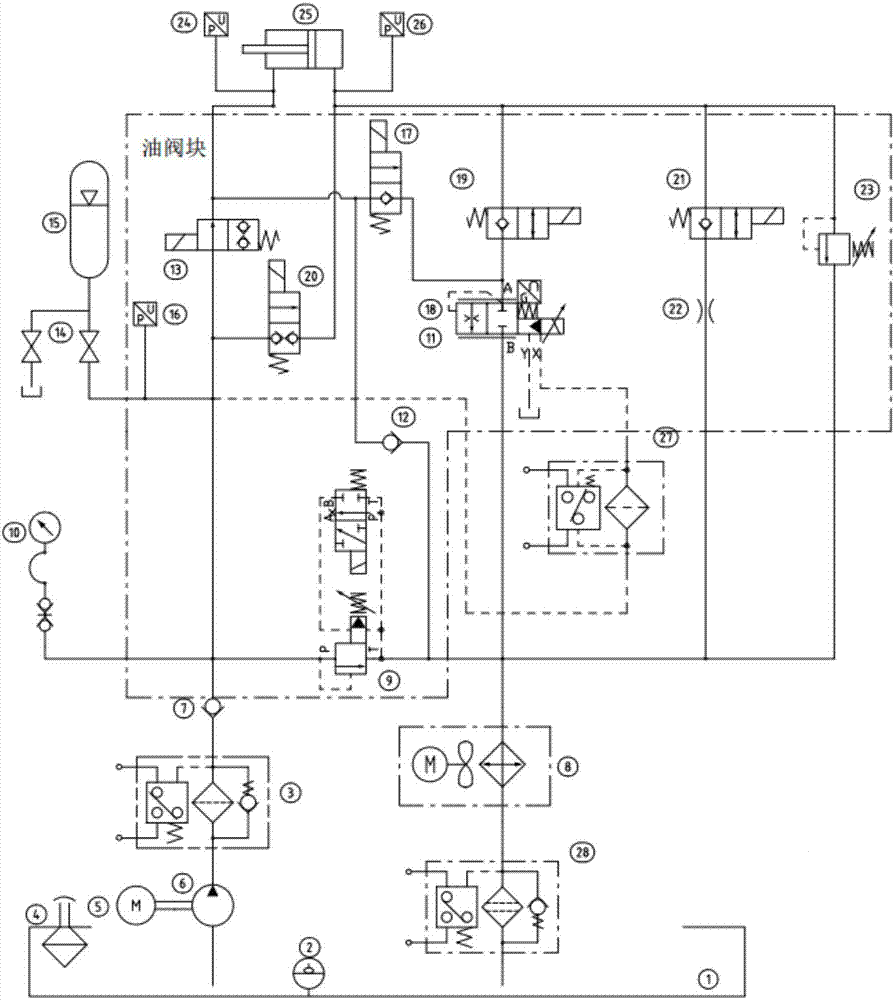

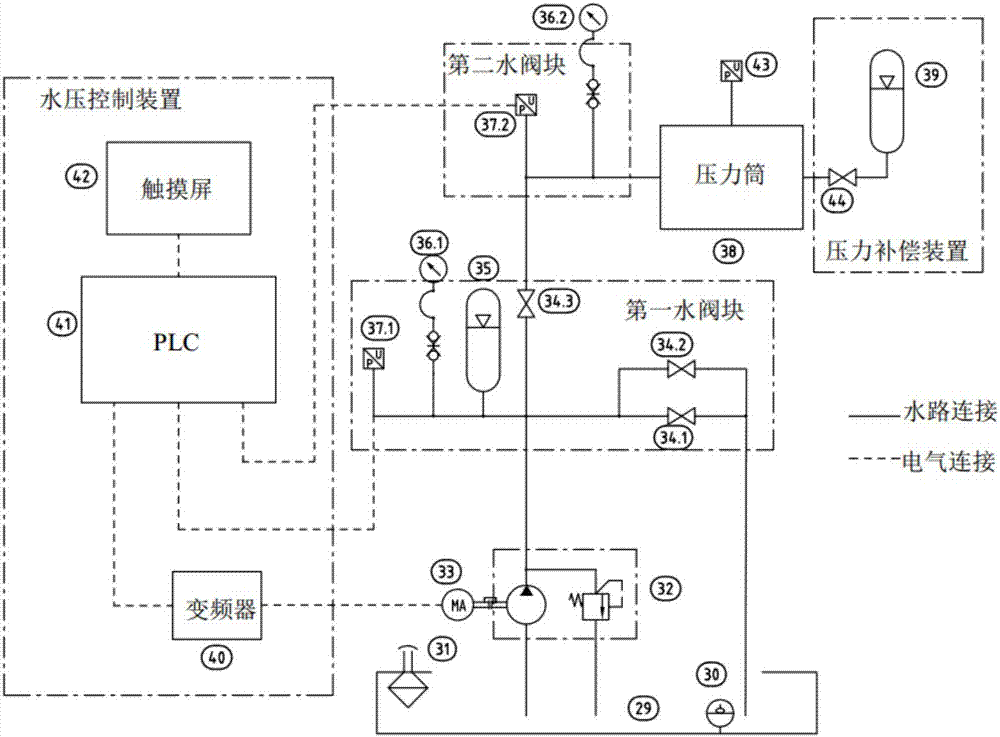

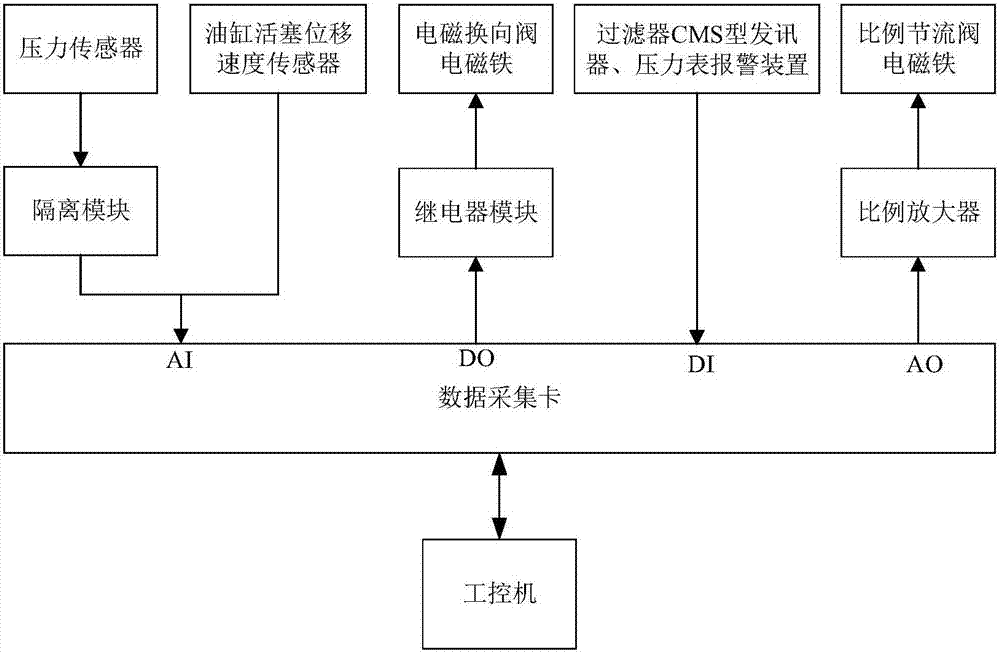

[0029] Such as figure 1 Described is the principle diagram of the hydraulic system of the example of the present invention. Among them, the pilot relief valve 9, the second check valve 12, the first electromagnetic reversing valve 13, the second electromagnetic reversing valve 17, the proportional throttle valve 18, the third electromagnetic reversing valve 19, the fourth electromagnetic reversing valve The valve 20, the fifth electromagnetic reversing valve 21 and the safety valve 23 are installed on the oil valve block. The oil tank 1 has the function of storing oil and providing the system with original parts to be placed and fixed. The fuel tank liquid level thermometer 2 displays the oil temperature and liquid level in the fuel tank. The first high-pressure filter 3, the second high-pressure filter 27, and the oil return filter 28 filter the oil to pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com