Novel high-performance forward-penetration film and preparation method thereof

A forward osmosis membrane, high-performance technology, applied in semi-permeable membrane separation, chemical instruments and methods, osmosis/dialysis water/sewage treatment, etc., can solve internal concentration polarization, do not have high water flux and low Salt backdiffusion flux and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

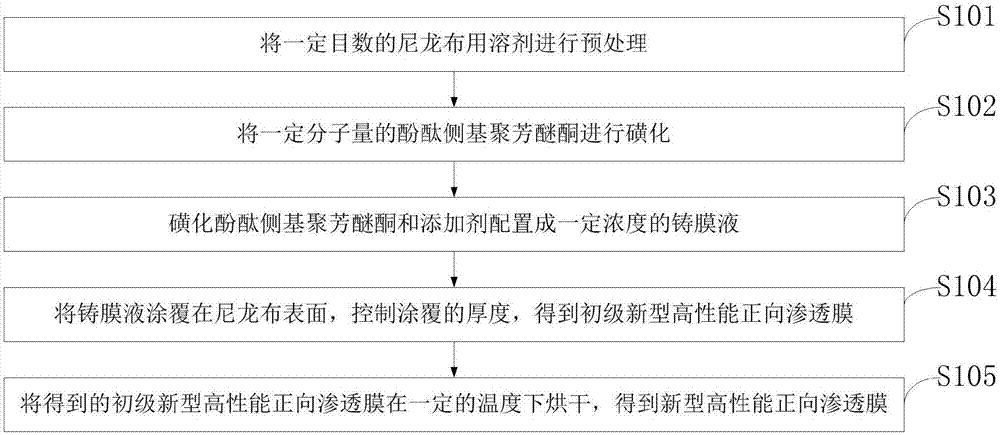

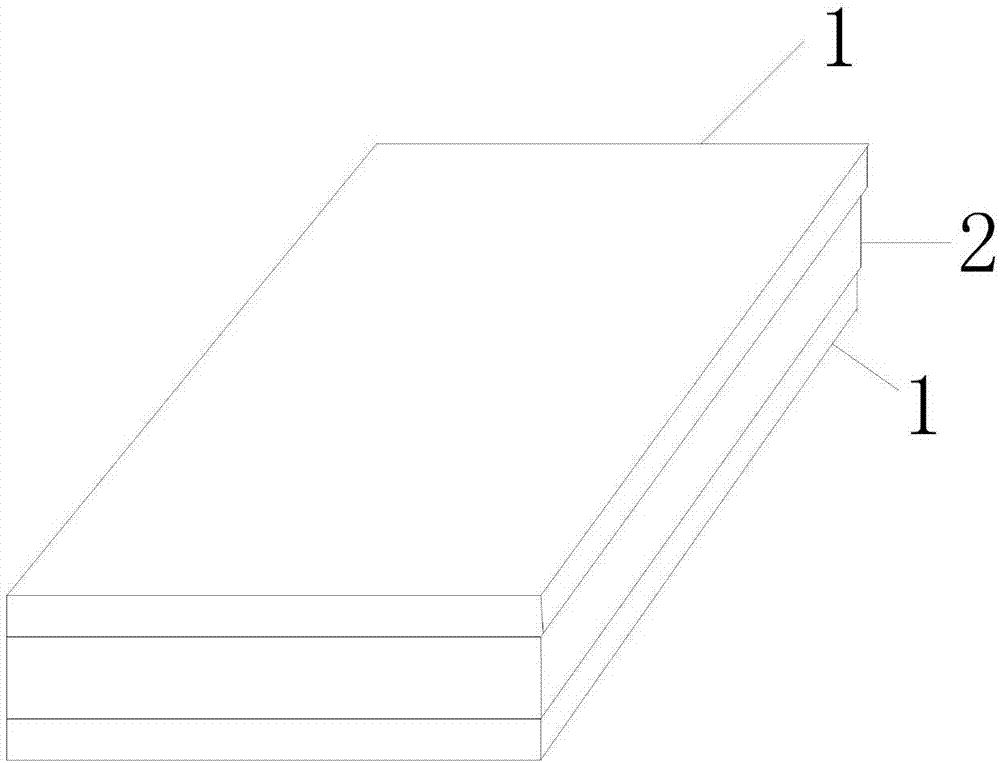

[0045] In the preparation method of the novel high-performance forward osmosis membrane provided by the embodiment of the present invention, it specifically includes:

[0046] Preparation of casting solution: take a certain amount and a certain molecular weight of phenolphthalein side group polyarylether ketone, anhydrous Na 2 SO 4 and concentrated H 2 SO 4 , Stir the reaction at a certain temperature for 6-12 hours. After the reaction, the reaction solution was cooled to room temperature, the product was precipitated with distilled water, and then the precipitate was washed with a large amount of deionization until the pH value was close to 7, and then placed in an electric constant temperature blast drying oven for drying. After mixing and dissolving a certain amount of sulfonated product, polyvinylpyrrolidone, acetone, N,N-dimethylformamide, dimethyl sulfoxide and N-methylpyrrolidone, a casting solution is obtained.

[0047] Pretreatment of the support layer: use a cert...

Embodiment 1

[0066] Stir 80wt% of N,N-dimethylpyrrolidone, 18wt% of SPEK-C and 2wt% of polyvinylpyrrolidone K-30 until completely dissolved, and let stand until defoaming is complete. Dip-coat the casting solution on nylon cloth soaked with N,N-dimethylpyrrolidone, dry at 50°C for 2 hours, dry and cool, then soak the film in deionized water for 24 hours at a constant temperature, and change the water during the period 2 times to ensure that the porogen is removed and the membrane required for the experiment is obtained.

[0067] Using 2mol / L NaCl solution as the driving solution, deionized water as the raw material solution, and the fluid flow rate on both sides of the membrane at 0.25L / min, the separation performance of the prepared forward osmosis composite membrane was tested, and the water flux was 120.65L. m -2 h -1 ; Salt back diffusion flux is 22.28g m -2 h.

Embodiment 2

[0069] 84wt% of N,N-dimethylformamide, 12wt% of SPEK-C and 4wt% of acetone were stirred until completely dissolved, and allowed to stand until defoaming was complete. Dip-coat the casting solution on nylon cloth soaked with N,N-dimethylformamide, dry at 70°C for 3 hours, dry and cool, then soak the film in deionized water for 36 hours at a constant temperature, and replace it during the period. Water was added 4 times to ensure that the porogen was removed to obtain the membrane required for the experiment.

[0070] Using 2mol / L NaCl solution as the driving solution, deionized water as the raw material solution, and the fluid flow rate on both sides of the membrane at 0.25L / min, the separation performance of the prepared forward osmosis composite membrane was tested, and the water flux was 113.65L. m -2 h -1 ; Salt back diffusion flux is 28.31g m -2 h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com