Harmless disposal technological process for organic synthetic waste

A harmless treatment and organic synthesis technology, applied in waste treatment, solid waste removal, plastic recycling, etc., can solve the problems of mixing impurities, degradation and crosslinking, physical performance reduction, resource waste, etc., and achieves low cost and effective Effect of recycling and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the examples, and the mode of the present invention includes but not limited to the following examples.

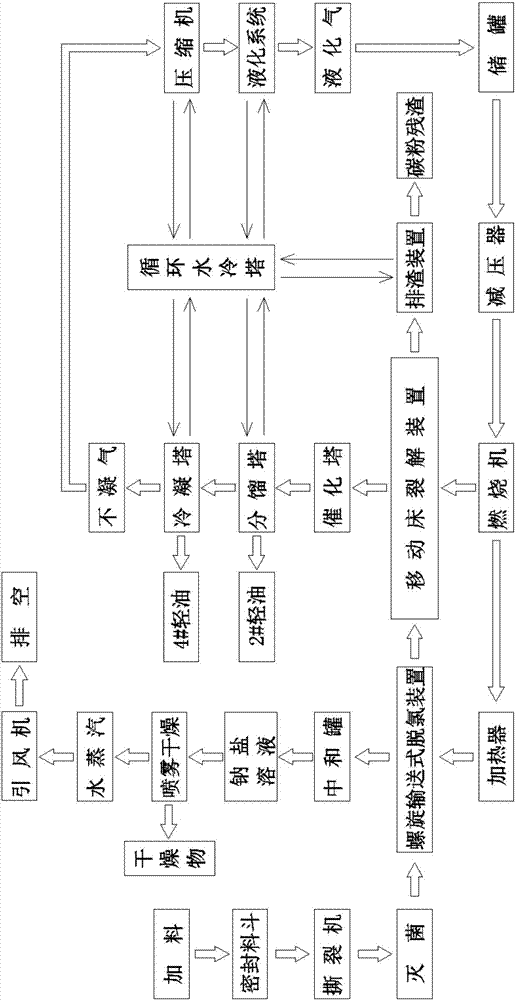

[0017] Refer to as figure 1 As shown, the harmless treatment process of organic synthetic waste includes the following steps:

[0018] (1) The crushed garbage plastics are put into the feeder from the feeding conveying device for sterilization, and the sterilized garbage plastics are pushed into the screw-feeding degassing device by the feeder, and the heater heats the screw-feeding degassing device The temperature reaches 300-500°C, so that the plastic can remove harmful gases during the conveying process, and the feeder includes a sealed hopper and a tearing machine;

[0019] (2) Continue to push the molten plastic after the removal of harmful gases into the moving bed pyrolysis device heated by the burner to a temperature of 600-800°C for pyrolysis, generating pyrolysis gas and carbon powd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com